Playing devils advocate here.

I like John's idea, it stirs the grey cells up to allow you to think out the box, is it new ? No, similar has been done for years but is it new to the forum readers ? that's what matters.

In a conversation on the phone the other day with Tony we discussed a lot of this and the negative side of the conversation I have is cost. John has quoted material cost and material cost X 2 for labour.

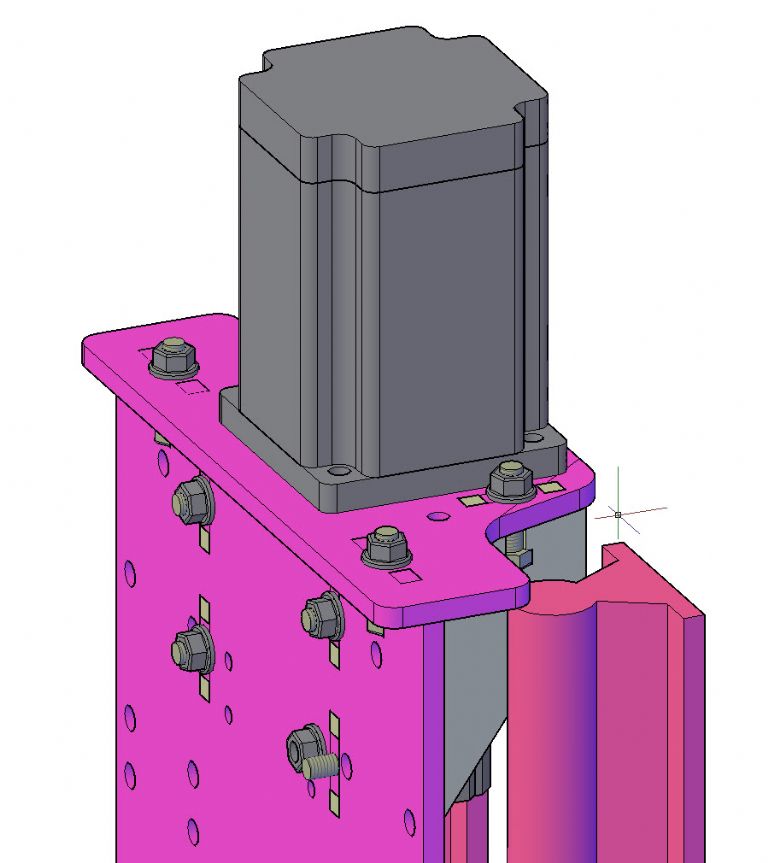

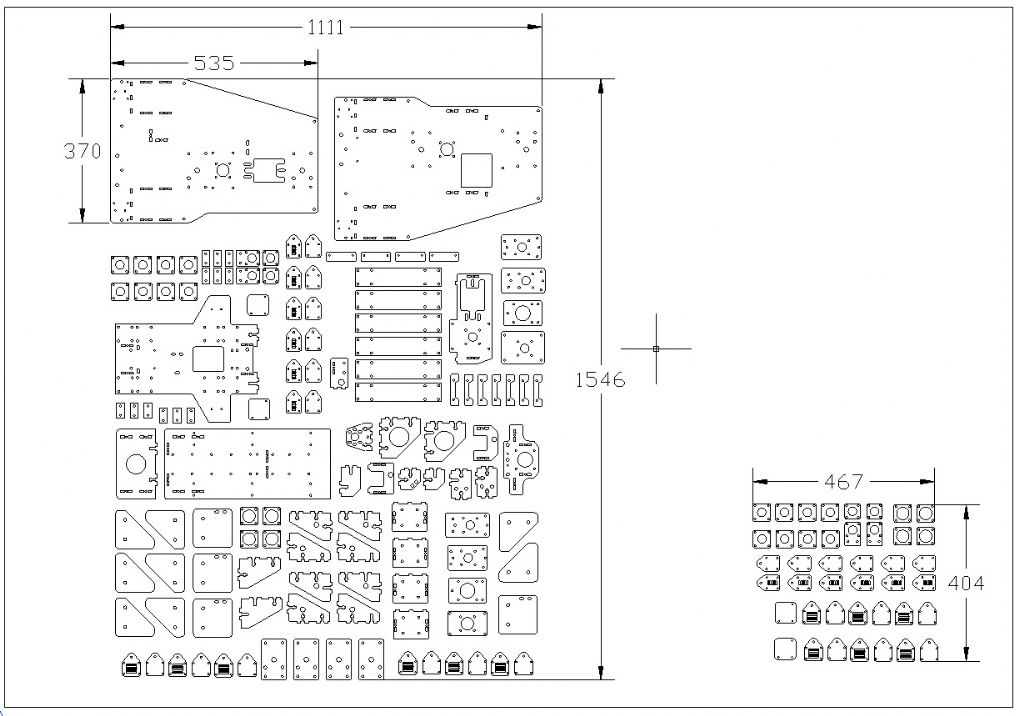

Now working from the layout drawings that John put up and taking the stepper motor as a size 23 for scale I did a quick work out and that first full sheet alone would cost me about £240 and I have very good laser cutting contacts.

Now material costs would be about £30 for this sheet at bulk rates and so total cost based on Johns figures should be £90. There is a big discrepancy somewhere.

Laser cutting works on a material cost and cost per inch or millimetre the machine has to travel, they know these costs to a fine art. That's why when you send a job in for cutting they always program it up before they get the order so they know the price.

If you then price up the common extruded alloy that a lot of routers use this method becomes expensive, at least in the UK on our prices.

However now for the positive bit, anyone of a squeamish disposition as regards CNC need read no further, thank you for your time.

On the market in the UK are cheap plasma cutters that can be bought for around £200. They use single phase and compressed air, no expensive gases or rental bottles.

Do a search on Ebay in Industrial tools for Cut40, if you search by lowest first you will get some 2 pin plugs followed by the consumables, tips etc which are very, very cheap.

Now if you get your CNC, bolt a length of box section to the bed sticking our with the torch on the end, pack the sheet you want to cut so it's just touching and clear of the bed movement if follows that any moves the bed makes will be transmitted to the torch.

Remember those 2 pin plugs [ incidentally Maplins are cheaper ] if you wire a push button switch to a length of wire and plug into the plasma cutter.

Now put the switch onto the spindle so any programmed Z move makes contact.

Is the light coming on ?

So you program your part, allow for the cut width just as you would with a milling cutter.

Z comes down, hits the bed [ best to put a sheet over the tee slots or fasten a sheet to the top of the box section ] plasma fires up and it goes round and cuts your shape.

Quick, easy, low cost and an extra manufacturing technique at your finger tips.

Incorporate John's captive bolt system and tenons and you have yet another skill.

John S.

Anonymous.