Thanks for the further replies and info.

pgk, whilst long reach hedge trimmers are great for allowing you to stay on the ground and still cut tall hedges, this only really applies to A-shaped hedges; to cut the tops of flat-topped hedges you still have to get off the ground yourself if only in order to see what you’re cutting. The long reach cutters do, however, allow you to easily cut right across a wide hedge once you’re up there.

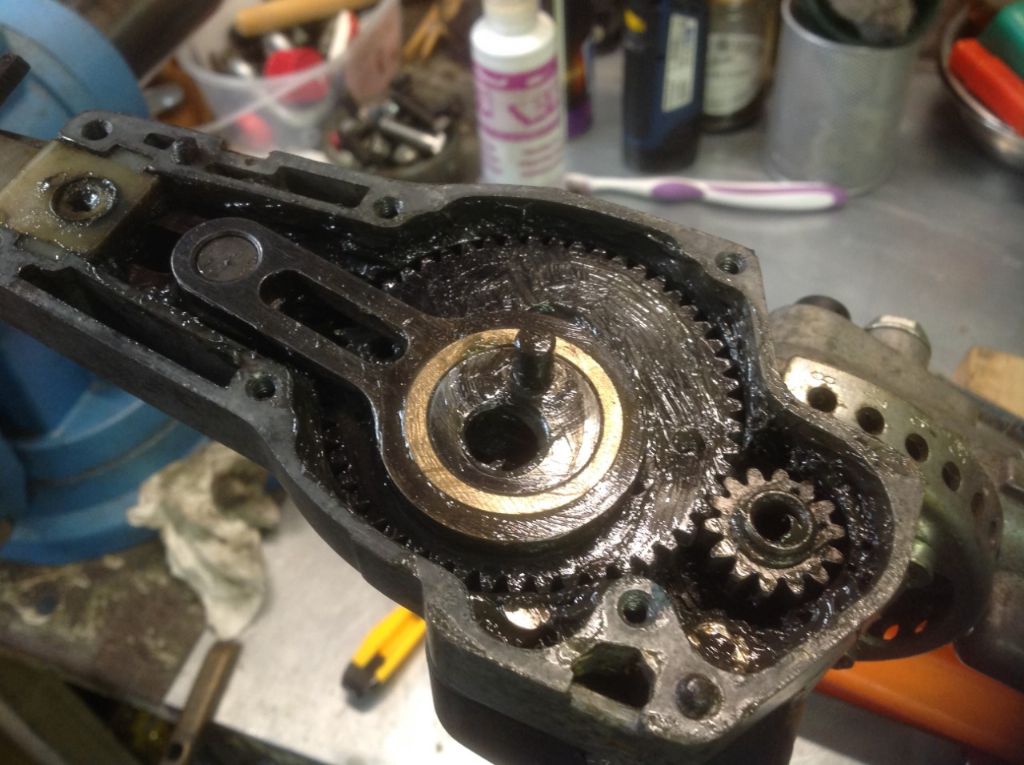

NDIY, you may be right about the lubrication. However, given that in all the examples of these gear boxes I’ve examined there was as much (or more) good quality grease in the gear boxes as when the machines left the factory I’d want to qualify your statement: if lubrication failing to protect critical surfaces was the cause of bearing failure in the examples I’ve handled, then that failure can only be laid at the door of the manufacturer for designing a gear box or recommending a grease that did not effectively distribute lubrication to the places that needed it.

I’ve voiced my own reservations about the video, but I’m not quite sure what you objected to. What did he get wrong in installing either the new conrods or the 6x10x9 bearings in the top and bottom of the gear case? I wouldn’t have used a hammer directly on the small bearing like he did, but he got them the right way up, didn’t he?

Nigel, yes, the carbs on Stihl stuff can be temperamental. One thing I’ve discovered only recently is the value of doing a leak-down test on two stroke carbs before you go changing the diaphragms, gaskets etc., or the whole thing. I found that all three of the carbs I’ve had on one piece of Stihl equipment were not airtight at either the metering end or the pump end or both. Curing that can help cut down on guesswork. I’ve not yet found non-OEM conrods or spur gears of the kind needed in these particular gearboxes, unfortunately.

Clive, I’m not quite sure how to understand your third paragraph. When you say a filler piece is needed around the outside of the bush, is this simply because no bush of the right dimensions is available in this case? I’ve not yet fully explored the sizes available so I’m not sure what choices I have. Mark’s earlier suggestion of a thin-walled bearing is also still attractive as long as I could get one of a width nearer to the required 6mm than 4mm, or somehow compensate for this dimensional discrepancy.

Interesting to see that Stihl use a caged rather than an uncaged bearing in the conrods of one of their more recent hedge trimmers. I suspect I don't need to be told why.

Bill Phinn.