As you say, Mach 3 and LinuuCNC have the capacity to do what you want. Both ot them will have an internal variable in the stlye of CURRENT_X_AXIS_VALUE. You would have to write a macro that runs continually and compares that value to your required one and then dives off into an interrupt routine that rings the bell when the values become sufficiently close (not necessarily 'equal' ).

To do this in principle in either program is not difficult, but it is the time and effort spent learning how to do it that will weary you.

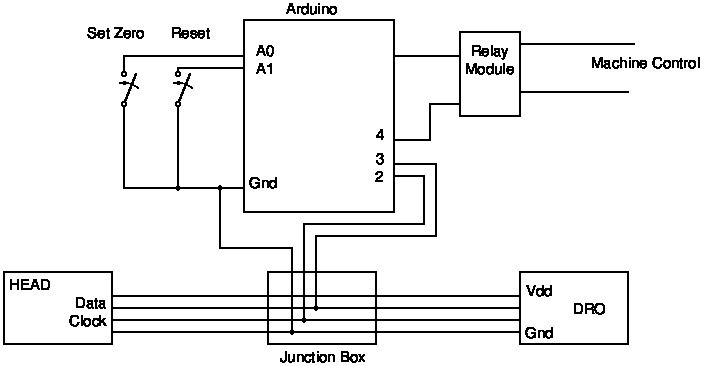

Someone has posted here an Arduino sketch that does a DRO summing (quill and knee). It would be possible to use that as a building block for what you want. You can intercept the signals from the scale, let the relevant part of that program decode them and them perform the routine described above for Mach. You would need to give it both the current value and the desired value so it can do its work.

The main thrust of this is to suggest you do some trials on the human-machine interaction aspect of your idea before going much further. Stopping something moving on the sound of a buzzer (triggered by your pulse) is not repeatable. What you do at the moment is to look at the DRO display, see how close it is to zero and how fast it is changing and adjust your handle turning to suit.

Rig up a dial indicator and a microswitch-triggered buzzer on the machine. Set the bzzer to sound when the indicator is at zero. Now cover the indicator and drive into the microswitch. See how close to zero you get. Repeat nine more times.

An analogue dial with a moving hand (or its on-screen equivalent) or even watching the numbers of a digital display count down will help you a lot more than a single tone.

Think of it in reverse: starting an athletics race or the Christmas tree at a drag race. The best athlete is the one who goes on the 'B' of the bang, not the 'G'. The winning car is the one that takes off as the lights start to dim, not when they are fully extinguished.

If you want to take the quadrophenia route, then the parking sensors on a modern vehicle might be a good model. The programming is not trivial as it has to take into account not only distance but speed and acceleration. It would be interesting to experiment to see if you can stop your car the same distance from the brick wall every time, just using the onset of the continuous tone to guide you.

Edited By DC31k on 01/05/2021 11:39:44

duncan webster 1.