Posted by Andrew Tinsley on 17/10/2021 10:25:58:

…

I am just finishing off the mechanics of a coil winder , so I can wind my own. Anyone any suggestions as to how to calculate the required inductance? Most load reactors laminations are like those usually seen on 3 phase transformers. Is there any reason not to use a lamination stack for each of the 3 inductors. I ask simply because I have a large supply of such laminations.

Andrew.

You will need an Iron Core to make the inductor reasonably small physically!

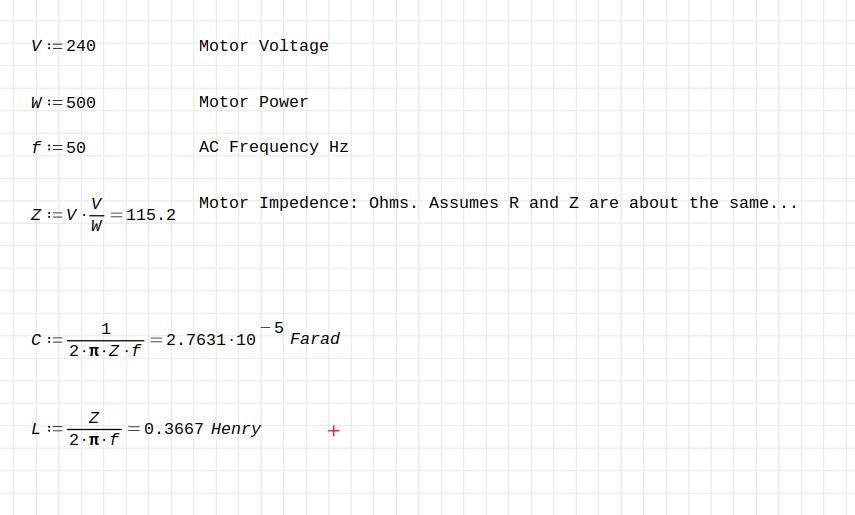

I'll have a go at the calculation: the formula are correct but I've made a big assumption about the impedance of the motor. Also, I am famously error prone when it comes to maths!

A simple Butterworth Filter is as simple as it gets – an inductor in series with a capacitor. Inline they make a bandpass filter, that is frequencies above and below 50Hz are filtered out.

The calculation assumes a motor consuming 500W from a 240V source, and that the impedance of the motor is the same as it's DC resistance R=E²/W. Trouble is impedance is the sum of reactive components, and a motor is mostly inductive, with a dash of capacitance. Better to measure the motor's actual impedance at 50Hz, and I think it will be found to vary with load, which complicates filter design.

However, the sum above suggests 27uF and 0.4H.

The reason reactors are expensive is 0.4H is a lot of turns, and the copper has to be beefy enough to take the current without overheating, here a few amps. The reactor is a fairly hefty lump of metal and three of them are needed, £££.

John Sykes mentions a couple of problems with old motors and VFDs, but not the worst, I think. It relates to the design of the bearings and how they deal with earth leakage currents. Basically, old motors earth through the working part of the bearings, and this causes spark erosion. The effect is quite small when the motor is fed generated 3-phase, but the sharp edges of VFD generated 3-phase cause voltage spikes when the bearing sparks. The spikes worsen erosion and also stress the motor's insulation. Unfortunately, the insulation of older motors is poor by modern standards, and a duff bearing is likely to punch holes in it.

Apparently pretty much all motors made after 1970 address the problem. If the motor was made before 1970, they become increasingly risky with age.

Personally, old electric motors make me nervous, VFD or not. Although reassuringly big and well-made, behind the scenes the years are unkind to electrical insulation! So are overheating and damp conditions. A proper insulation test is needed to reveal if there's a problem.

Dave

Edited By SillyOldDuffer on 17/10/2021 12:52:44

Andrew Tinsley.