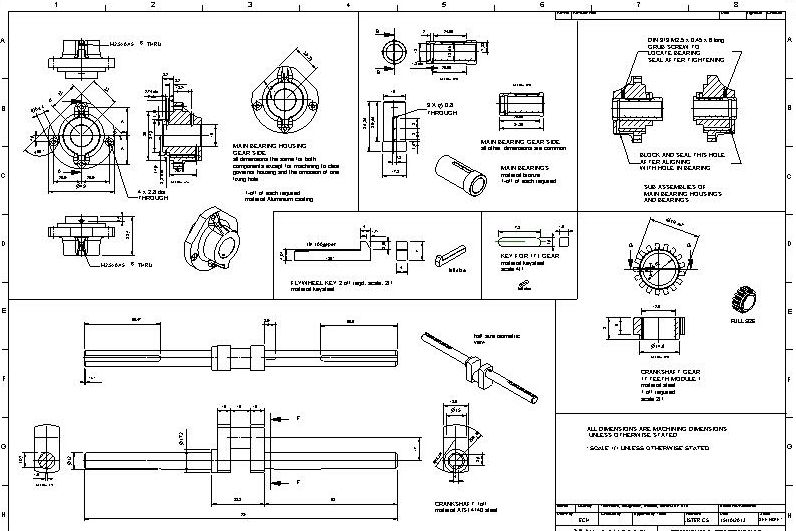

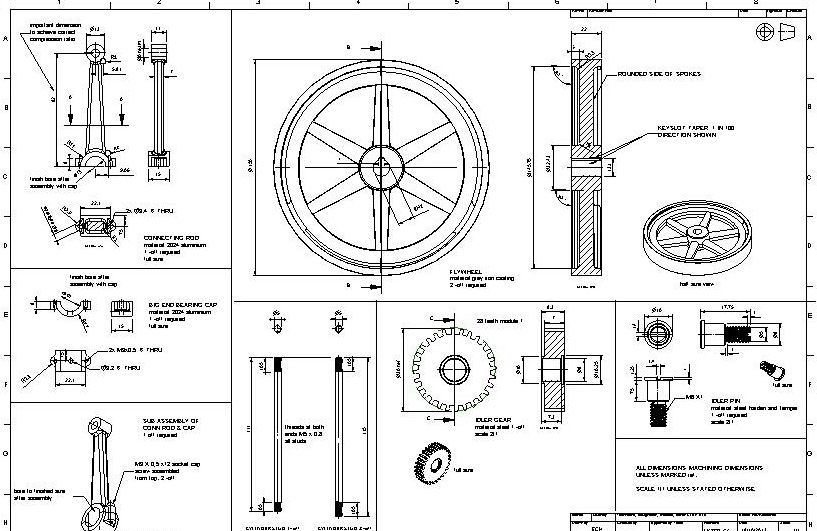

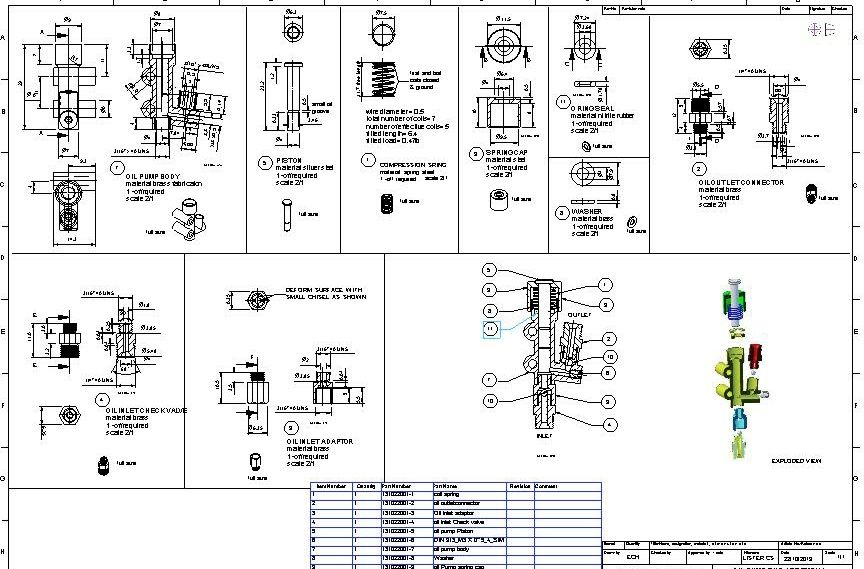

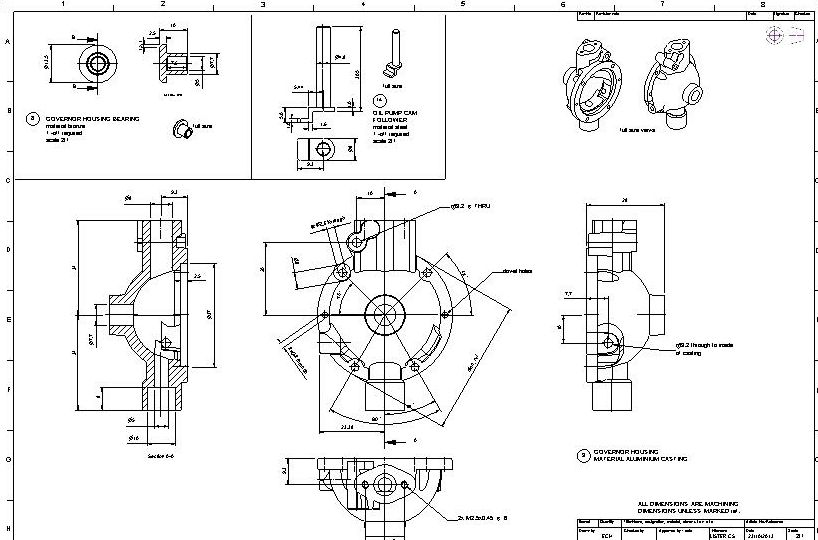

Lister Diesel Engine

Lister Diesel Engine

- This topic has 113 replies, 17 voices, and was last updated 19 January 2015 at 15:52 by

Larry Coleman 1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)