This is my first modelling project. I am 63 y.o. and hoping that my skills set will see me through.

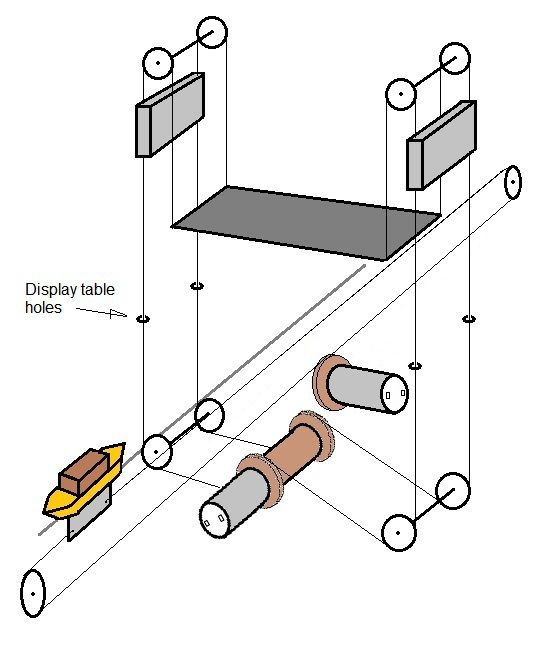

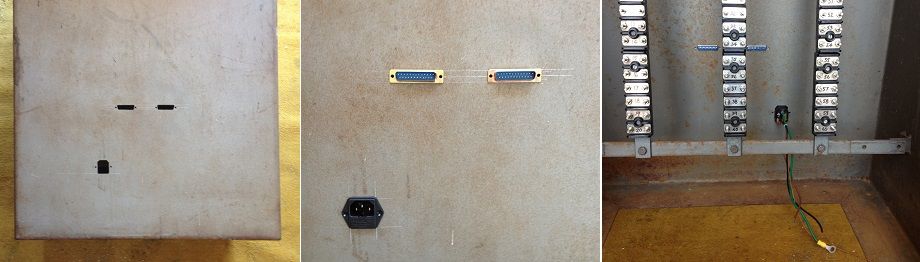

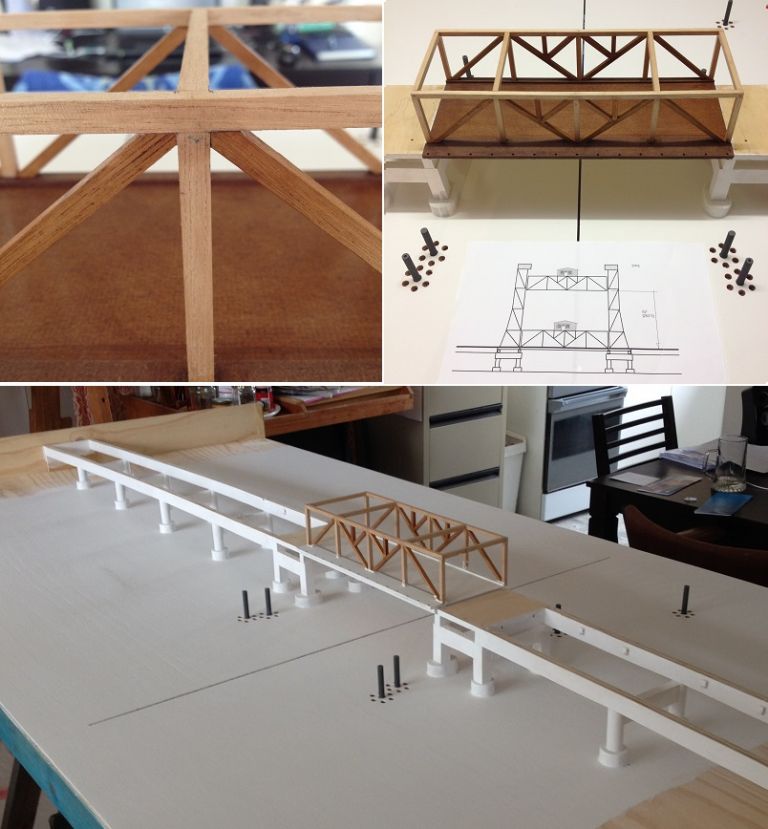

A while ago our local maritime museum acquired an antiquated lift-span bridge console (1964-1995). They wanted to know if it could be used somehow as an interactive display. A friend, who knows my background in avionics (RAAF 1980-86), and works at the museum, asked me to examine the console. After a brief discussion, with the curator and president, I got roped into converting the console to operate a working model of the lift-span bridge come diorama. Nobody there had the skills to build the model, or do the electronics, To do both projects (console and bridge) I became a volunteer worker. Gratefully, they left me alone to do the whole lot (no bosses).

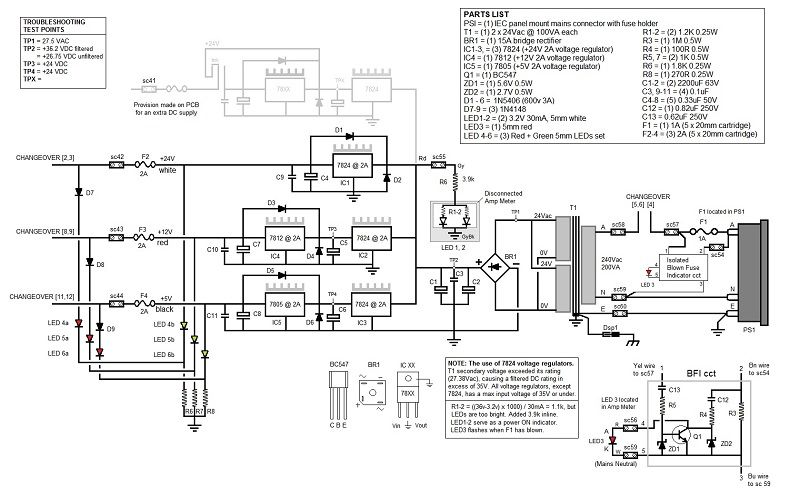

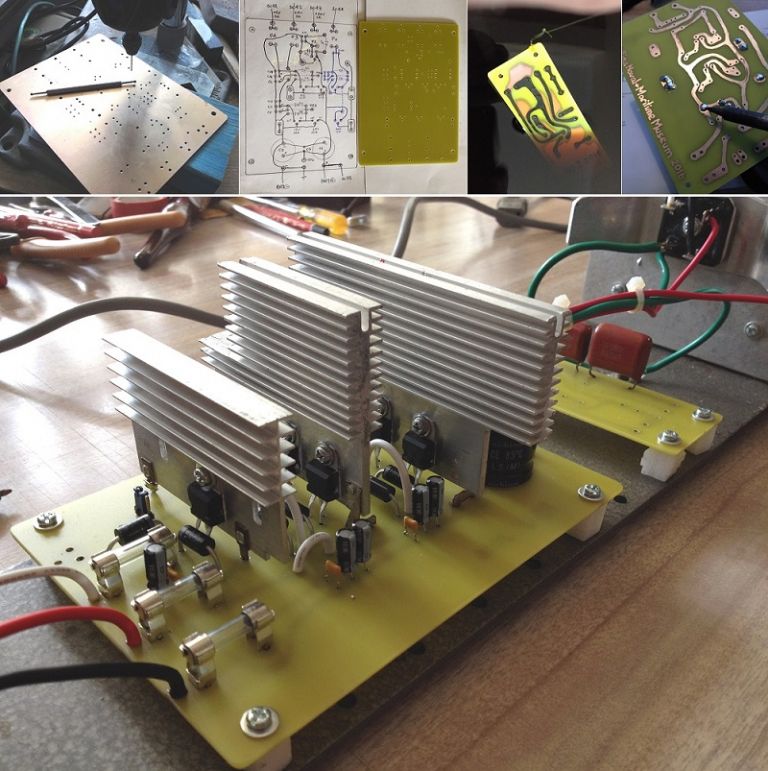

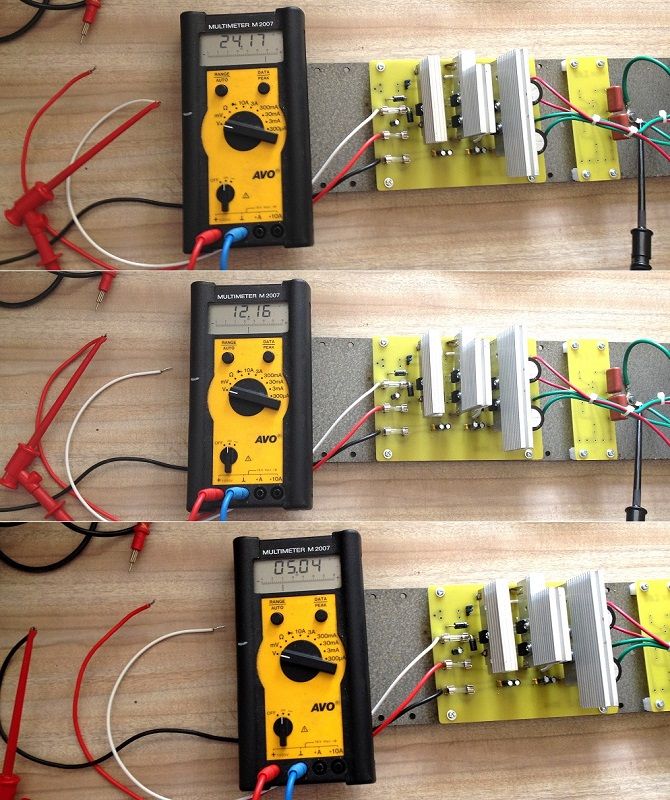

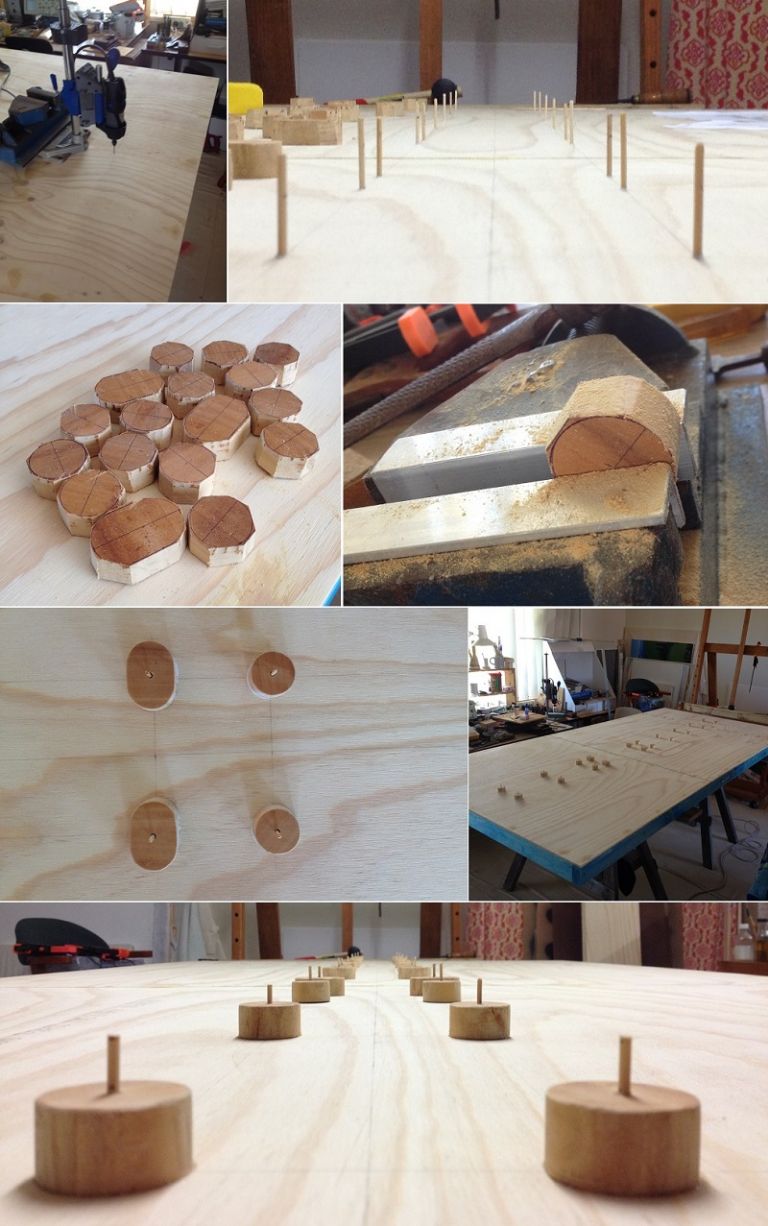

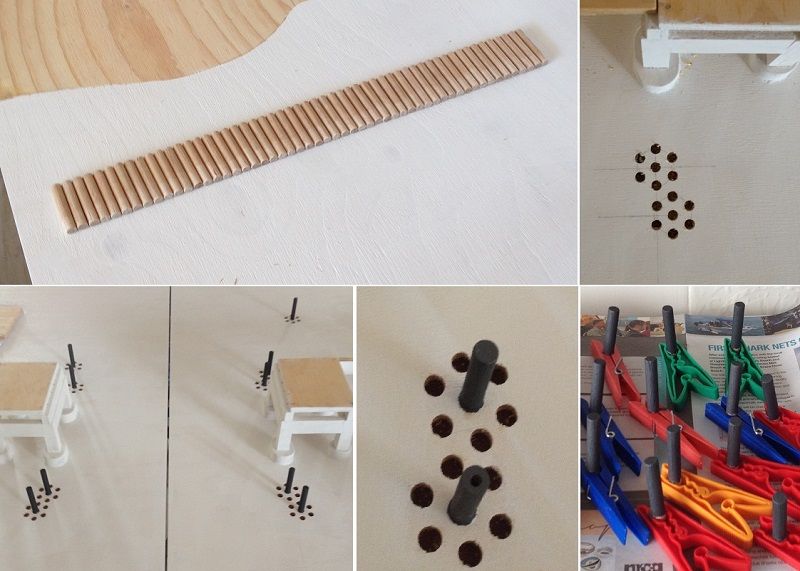

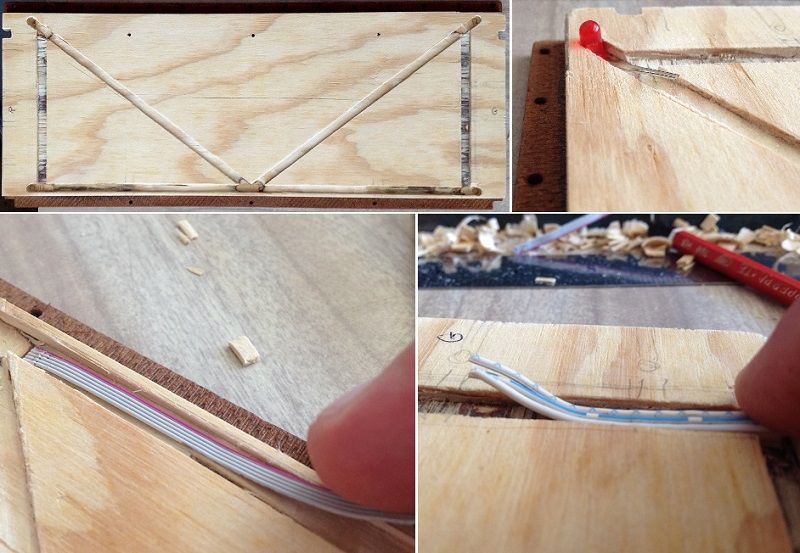

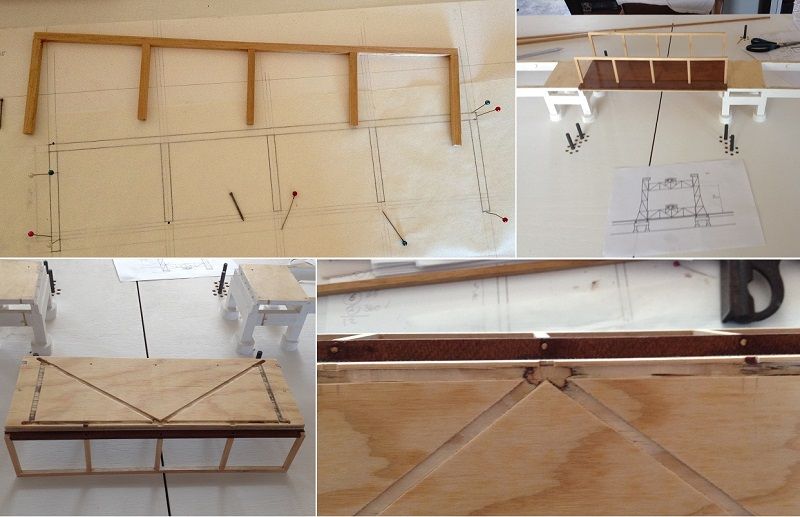

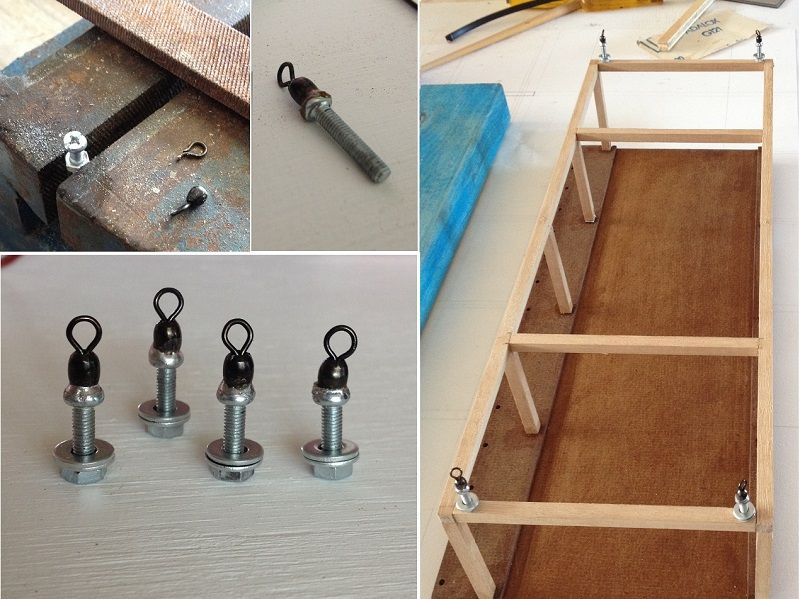

Actually, the whole museum is run by volunteers. It is a non-profit organisation, so it has limited funding. This project is going to be built with minimum expense. The museum workshop has few tools and space to build this display. So I am building it in my lounge room (I have no garage). Besides a Dremel drill press with a bent spindle, and a few electronic instruments, everything is built by using basic hand tools. So please accept my methods as I use them.

The lift-span bridge is at Wardell, NSW, Australia. The museum is in Ballina, the next town downstream on the Richmond River.

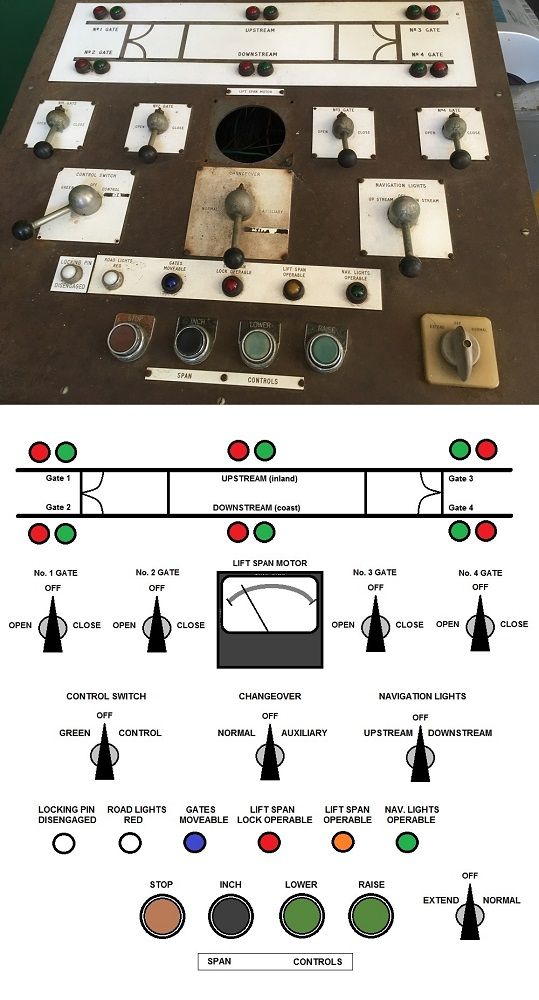

Here is the console as photographed when it arrived at the museum:

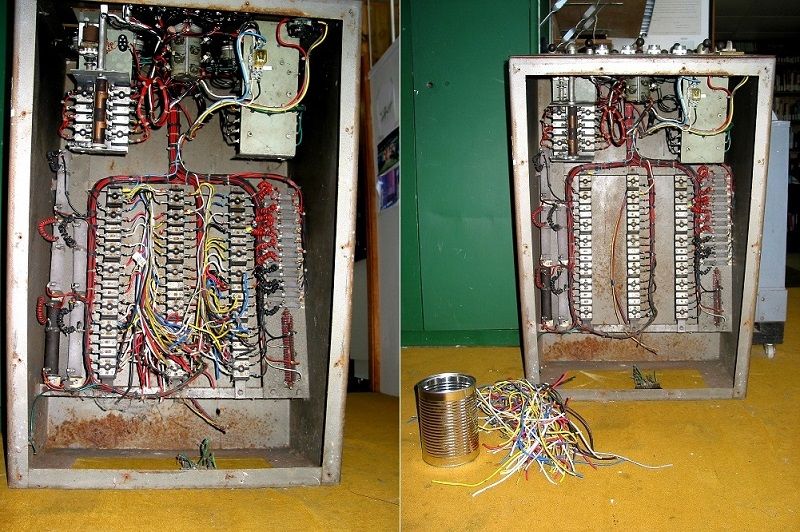

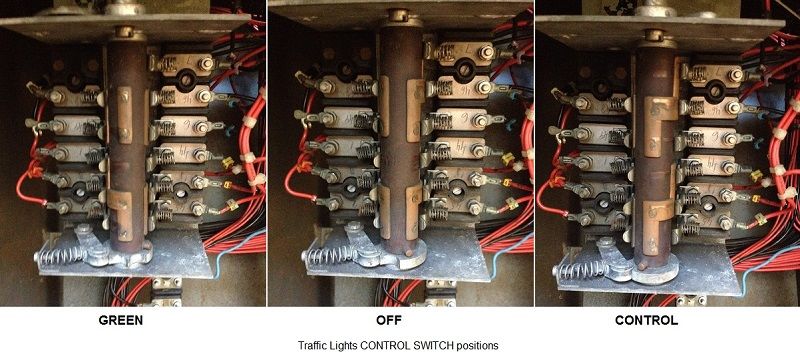

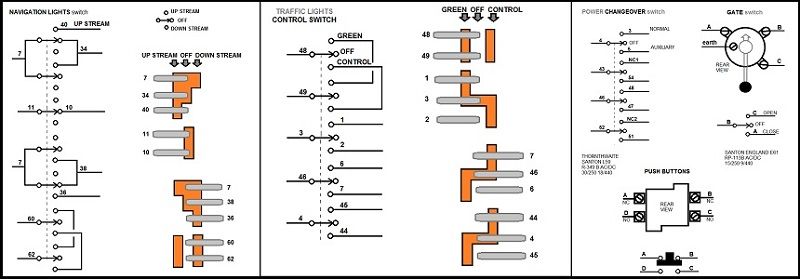

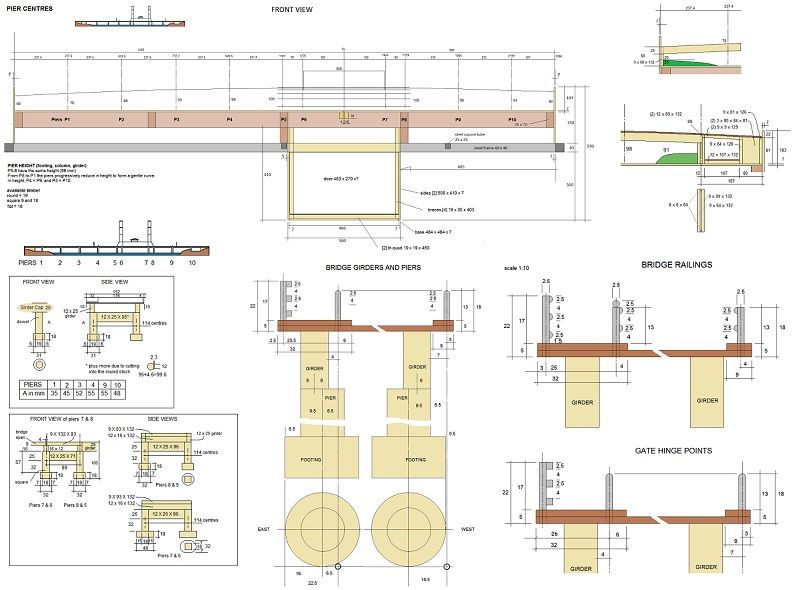

I was unable to get any schematics for the console, so I have to reverse engineer it to understand how the switches work. Also, the bridge plans were not available for the public, or any information on how to operate the bridge (a security caveat). Instead, I got as many photos I could from the Internet about the Wardell bridge, and measured the span length and the width of the bridge road. From these two I was able to extrapolate the rest of the measurements from the photos (I snapped many photos as well).

As to the bridge operations, I interviewed the current operator. I was informed that he cannot tell me how to operate it. However, he was able to tell me what each switch and button did (though he has never seen the control panel before). From this, and many hours of deciphering the information, I was able to work out the operating sequence. It is not a simple matter of raising and lowering the span. In a nutshell, there is much safety precautions, and both road and vessel traffic conditions need to be controlled.

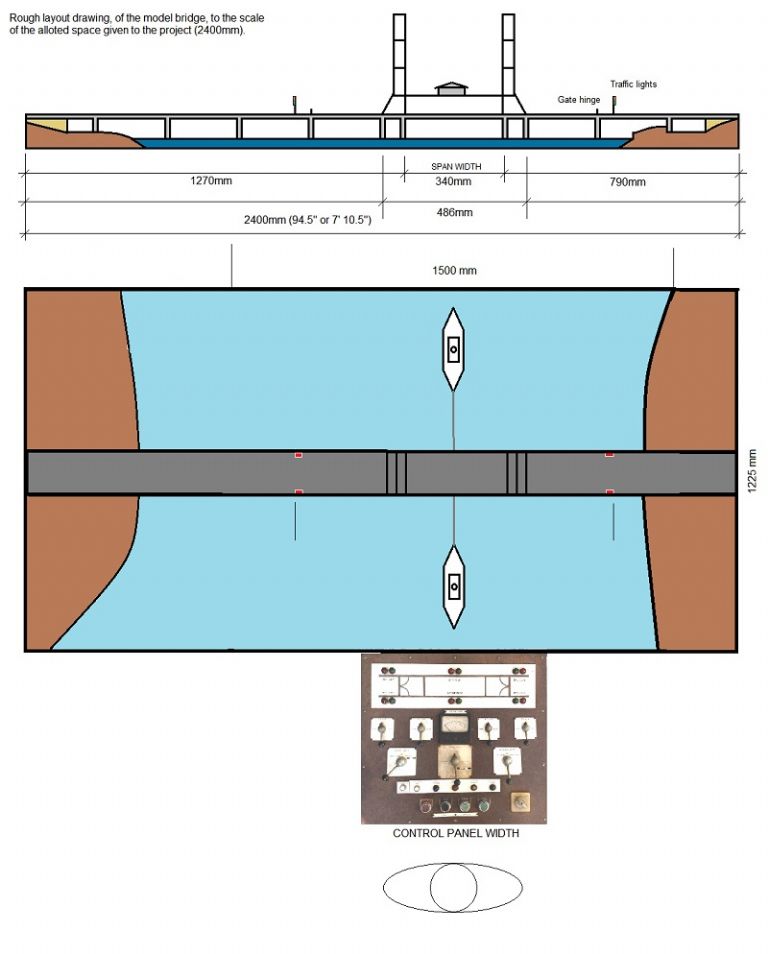

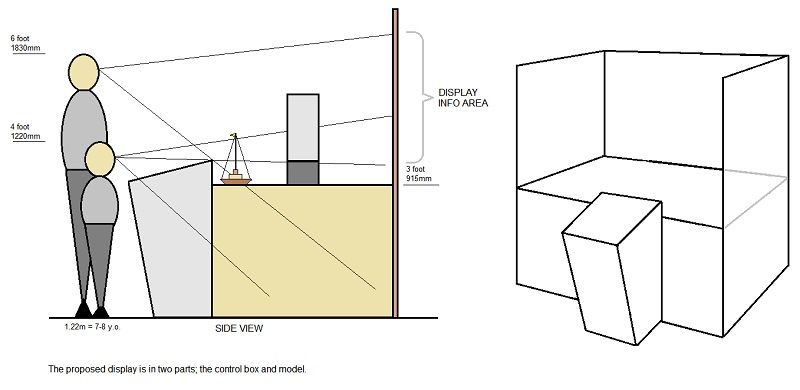

The curator wanted the model bridge to fit across a display area of 2400 x 1200 mm (8 x 4 feet). From my measurements, a 1/72 scale would fit the bridge nicely into the 8 foot length. I made plan drawings for the model to that scale. Later I discovered that a 1/76 scale would have been better due to the resources available for that scale, being OO model railway gauge.

to be continued:

Perko7.

Perko7.