As an aside – like Ray, I purchased the Aldi bandsaw and I'm generally happy with it. I've built a vertical stand for it (which I suspect it will mostly be used with) but not found a suitable bit of plate steel for the table as yet. The horizontal stand included works well but needs 'squaring' up carefully – I've used it to cut steel bar, block and pipe up to about 60mm square.

The only thing I haven't really liked about the horizontal stand is the cam-vice. Most times it holds firmly enough but occasionally it doesn't. As this might well lead to the blade jamming or breaking, I decided to try to improve things.

I have several sub-tables for my mills & lathes and occasionally use them in my McMaster power hacksaw to hold things that are a bit awkward. The McMaster vice is a very solid bit of kit, OK for square bar and such but not ideal for odd shaped and smaller things. So I clamp these on a sub-plate and then grip that in the McM vice for cutting.

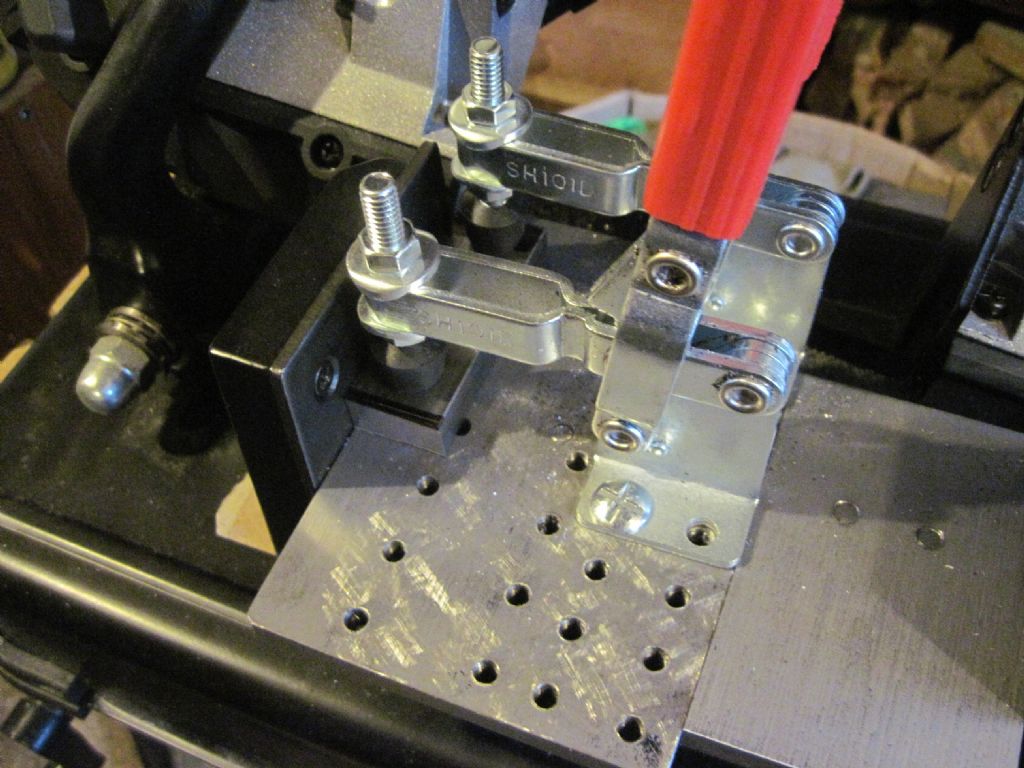

This gave me an idea for the Aldi. I removed the 'cam' jaw and cleaned up two bits of hot-rolled plate from the scrap bin, that together fit the available space on the existing vice between the fixed jaw and rear block. I drilled and tapped some M6 holes, originally for my usual clamping sets but it occurred to me to also try some Axminster hold downs, so spaced the M6 holes appropriately. They do work and are quick in use but another problem emerged in that the blade tries to pull the work away from the fixed jaw (which might also help explain the problems with the cam arrangement) – as it's running towards the other end. It's not caused me any real problems yet but I need to experiment further with clamping or perhaps a new (screwed) jaw of some kind.

I've also been meaning to get some new blades for the Aldi (I'm a happy Tuffsaw customer too) which I think will also help improve things.

Regards,

IanT

Edited By IanT on 22/10/2020 11:41:26

Ady1.

Ady1.