Learning CAD with Alibre Atom3D

Learning CAD with Alibre Atom3D

Home › Forums › Model Engineer & Workshop › Learning CAD with Alibre Atom3D

- This topic has 840 replies, 78 voices, and was last updated 8 February 2023 at 23:52 by

Ady1.

Ady1.

-

AuthorPosts

-

14 March 2019 at 00:29 #400261

Nigel Graham 2

Participant@nigelgraham2Errr, thank you SiilyOldDuffer but with great respect I can't quite understand what you mean, beyond your having totally misrepresented me!

I am not blaming the software either.

I have no idea what you mean by "world view" but I tried all 3 CAD programmes – plus AutoCAD 2000 – to see what I would find the best for me.

Neill – Sorry, but your comments about "parametric", "object trees" etc are over my head. I think they are for advanced users.

Your second paragraph does not apply to me. I am used to orthographic drawings by default and am not trying to "project" them anywhere; but I use isometric as an auxiliary tool.

David – I tried to import a TurboCAD file into Alibre, to see if it's possible. I found Alibre does not read TCW files.

I appreciate that CAD generates "solids" from planar figures, but in different ways giving the same shapes with very different internal characters and reactions.

It took me a long time to realise why I could not draw a simple cross-section. Apart from the term not being used anyway, the programme did NOT tell me why I could not make it work.

Those last two observations refer to TurboCAD, but I am not convinced any CAD programme would be any better.

I understand the notion of drawing a model by adding geometrical objects to each other, but 3D uses many ways to do so, and it is by no means obvious which to use and which not, how and why. Anyway, an orthographic drawings is also a set of objects stuck together. The only difference is in using a single work-plane.

Alibre, TurboCAD and Fusion360 essentially do the same things though in different ways. Fusion initially looked simpler than TC but I found it's about the same level of difficulty. It also seems to force the 3D-then-2D route as Alibre does.

TC offers you the 2D/3D choice from the start, if you do not need to draw in 3D. Orthographic-only is still difficult but at least avoids its 3D's incomprehensible morass of combinations and permutations of multiple "solid" generators, work-planes and co-ordinate systems. I don't know, but suspect Alibre and F360 will have comparable systems, as they all do fundamentally the same things.

Following a series to make a specific drawing of some specific, fairly simple example teaches you how to draw that example; but whilst useful you need far more than that to use CAD properly and usefully even for similarly simple items.

A video only shows you an expert demonstrating the software.

My requirements are simple:

1) A CAD programme that helps me to design and draw particular engineering items so I can make them.

2) Isometric: perhaps useful for clarifying awkward shapes and assemblies, but not essential.

3) The programme being reasonably easy and intuitive; with proper operating information available (some hope).

Rendered pictures merely add add a huge extra burden of skills, knowledge and work to the process.

Being able to make a prettily-coloured model is not itself a reason for doing so.. By corollary, recognising the limits of own abilities are a reason for not attempting that. I cannot learn how to make 3D CAD pictures, but I do not need to anyway, and do not see the why Alibre wants me to use a roundabout way to make the real drawings. I want to make metal things, not "paintings".

I have explained why I cannot change to Alibre now. I am perfectly well aware these programmes all differ significantly in how you use them, and there is no point in abandoning one I know enough to create admittedly-rough drawings, and start all over again with another!

Further, I now have quite a number of TurboCAD drawings, but Alibre does not recognise their file-types so cannot open them. I investigated this only today.

It seems I've found a gulf of understanding besides that already between CAD and me, but also between my CAD needs and others' preferences in using it.

14 March 2019 at 06:59 #400272 JasonBModerator@jasonbPosted by Nigel Graham 2 on 14/03/2019 00:29:02:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 14/03/2019 00:29:02:David – I tried to import a TurboCAD file into Alibre, to see if it's possible. I found Alibre does not read TCW files.

I don't think we can help you. Even with written instructions which you say you prefer you just can't read them. Look again at what David wrote. :

Nigel – it MIGHT be practicable to use work done in TC as a basis for Atom3D files. From you comments I believe that all your previous work is in 2D – this could probably be exported as DXF or DWG then imported into Atom3D

No mention of importing or opening Turbocad files.

14 March 2019 at 09:08 #400295 Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 00:29:02:

Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 00:29:02:Neill – Sorry, but your comments about "parametric", "object trees" etc are over my head. I think they are for advanced users.

Your second paragraph does not apply to me. I am used to orthographic drawings by default and am not trying to "project" them anywhere; but I use isometric as an auxiliary tool.

:

I understand the notion of drawing a model by adding geometrical objects to each other, but 3D uses many ways to do so, and it is by no means obvious which to use and which not, how and why. Anyway, an orthographic drawings is also a set of objects stuck together. The only difference is in using a single work-plane.

Hi Nigel,

I realise those things don't mean a lot – but if you were to work through the tutorials, they might make sense.

I think you demonstrate my second paragraph is exactly the issue, although perhaps I shoudl have said 'extrude' rather than 'project'. With an orthographic projection you have to develop drawings by taking shapes in one plane into another. This means when you change to 3D you tend to try and draw the part up in the same way, drawing one view and extruding it, and as this is the simplest way of making a 3D part and systems all start with it you tend to start there -and get stuck there.

3D is far more than producing an isometric view of your part.

You might well produce simple objects in 3D by working from three planes, but for any complexity you will end up with many planes, allowing you to do things like interpolating shapes to get compound curves in 3D, projecting features off other features, rotating parts and sweeping parts along lines. Having been taught traditional drawing anything beyond the 'angled cut through a cone' approach gets pretty complex from an orthographic perspective.

It sounds to me like you are entirely comfortable, and probably rather competent, working with 2D.

| I cannot learn how to make 3D CAD pictures, but I do not need to anyway, and do not see the why Alibre

| wants me to use a roundabout way to make the real drawings. I want to make metal things, not "paintings"I think this is the basic issue – by definition Atom3D is primarily for 3D modelling, but allows you to produce 2D drawings if required.

As you just want 2D drawings you really are better off using a package that is 2D led or allows you to work in a predominantly 2D environment – TurboCAD is probably better for this approach.

Neil

14 March 2019 at 09:34 #400303David Jupp

Participant@davidjupp51506I'd say that there is significant benefit of using something like Atom3D even if you only want 2D drawings – it's often faster than a pure 2D approach once you get the hang of things, especially if you need cross section views, enlarged detail views, isometrics etc. Also when the design evolves/changes, the 2D drawings update automatically.

The vast majority of commercial users of Alibre produce 2D drawings for manufacture of their designs.

14 March 2019 at 10:37 #400316SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 14/03/2019 00:29:02:Errr, thank you SiilyOldDuffer but with great respect I can't quite understand what you mean, beyond your having totally misrepresented me!

I am not blaming the software either.

I have no idea what you mean by "world view" but I tried all 3 CAD programmes – plus AutoCAD 2000 – to see what I would find the best for me.

…

Hi Nigel, apologies if I've misunderstood you, but what you've been saying in the thread rather suggests the opposite. I'm trying to help, not criticise.

'World View' can be found on Wikipedia. I mean it in the sense of 'the fundamental cognitive orientation of an individual'. Briefly, our understanding of the world and the things in it is built on the sum of our individual experiences. Most of the time building on experience works extremely well, but it can cause severe problems when previous experience is inappropriate to a new situation. The way I run my life in South West England would need radical revision if I was stranded on a desert island!

What I'm getting from your posts is a strong belief that 3D CAD software should operate as you imagine it. At root your approach to drawing is orthographic, I guess for good historic reasons. Unfortunately none of the 3D packages take that approach. An orthographic mind-set has you swimming against the tide. Your search for a 3D CAD package in tune with your requirements may be doomed to failure – I don't know of one.

You're not alone; when 2D CAD first appeared quite a few professional draughtsmen couldn't cope with it. Not because they were incompetent, or because 2D CAD was outrageously difficult, but because their old drawing board skills had to be unlearned. In the next generation others came unstuck unlearning 2D and learning 3D CAD. Not had any success breaking bad habits myself, even though my doctor has carefully explained all the nasty consequences of my life-style.

If you want to persist with 3D CAD, I suggest:

- Ignore all previous experience. (This is really hard to do.)

- Do not make any assumptions about how the software behaves.

- Concentrate on one package only.

- Start at the beginning and patiently master the basics. (Hard to be patient!)

- Do not skip steps or jump ahead.

The Alibre Tutorial running in MEW coupled with the ability to ask questions in this thread is a golden opportunity.

My 'world-view' leads me to believe that there isn't a CAD package that meets Nigel's requirements. I could be wrong! Can anyone else suggest one?

Dave

14 March 2019 at 10:49 #400320Steve Skelton 1

Participant@steveskelton1Here's my experience for what it's worth.

I tried to use the package based on my AutoCAD 2D experience and fell flat on my face.

I then read the tutorials and had a lightbulb moment.

I found I had to forget everything I had learnt about 2D CAD and drawing board draughting and imagine I was trying to make the item from a solid block or adding to it in a solid block as if I was machining it (or welding on to it). I then found it made sense.

I am not suggesting I am proficient at using the package but if I think in terms of adding or taking away material then I seem to be able to do what I want.

Not sure if others are with this??

Steve

14 March 2019 at 11:02 #400324Nigel Graham 2

Participant@nigelgraham2Thankyou Jason.

Yes, I did read the verb "might", and I did try other file types including ones with the magic letters 'DW', but without success. Given the very long list of possibilities though, it would be very easy to miss the one that might work..

Neill – I did spot your accidental use of "project" but wasn't quite sure what it ought have been.

I'm familiar with the "extrude" principle, as it's a basic one in TurboCAD 3D too. TC though gives several different ways of producing a "solid" – extruding from a planar figure, and editing a "primitive" ready-made object being perhaps the main ones; and I spent lot of time experimenting with them.

I never reached the advanced levels of "sweeps" and the like, but I found even with those two basic actions the properties of the generated solids and their reactions to editing tools differ markedly, with no clear rhyme, reason, pattern or manual instructions to help you choose the right type where both will give the same figure (mainly cuboids and cylinders). I assumed this will be common to all 3D CAD packages, because they have to perform essentially the same calculations and routines behind the presentation.

The MEW example works because all such decision-making has been done for you, so if you follow the instructions carefully you end up with a prettily-coloured picture of scribing-block already designed, without you really understanding how. It's a rote technique, valuable as a primer, but if Alibre has the same subtleties as TurboCAD and no doubt "others available", a rote primer won't guarantee future success with your own designs.

I still have the drawing of the scribing-block's base from Part One – I even succeeded in enlarging its diameter and recessing its underside so a real version would be more stable.

[That's as far as I reached. I had bought the magazine in Smiths, and took out a subscription (itself not as simple as it had seemed) to start with the next issue, but I think it jumped one. I have not yet verified edition numbers but the Alibre series appeared to refer to things not in Part One.]

I do realise advanced CAD skills can let you make images that would be horrendously difficult to draw manually; but that can be a trap, as the components would become horrendously difficult to make on an ordinary lathe and milling-machine with normal model-engineering skills.

Don't forget our own projects as model-engineers are either new to our own design and can use modern design practices, or are replicas of machines built in the days of exquisite draughtsmanship by pencil, T-square and set-square. Either way they have to suit our own workshops and craft abilities.

Having said that, I do know a lot of model-engineers now are using small CNC milling-machines and 3D-printers, so provided they still ensure the design suits the machine, the problem of physical difficulty is reduced somewhat.

(I recall seeing my first CNC mill in the factory where I was a storekeeper. One of the work-pieces for which it was intended was carved out of a big aluminium-alloy slab. The first attempt revealed it too large for the machine, which itself was sizeable; so while that batch was milled conventionally the drawing-office re-designed the part to fit the CNC mill! Pencil and paper designs, too.)

You still need to understand both Design and CAD. They are separate. The latter is extremely difficult, and exists to express the former as images.

14 March 2019 at 11:11 #400328 JasonBModerator@jasonbPosted by Nigel Graham 2 on 14/03/2019 00:29:02:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 14/03/2019 00:29:02:My requirements are simple:

1) A CAD programme that helps me to design and draw particular engineering items so I can make them.

Can you show us an example of what you want to draw, just a link to a photo or drawing or post a photo or screen shot of the sort of thing you want to draw. maybe if you can see it being drawn in a 3D package you will get a better idea of whats involved.

14 March 2019 at 11:59 #400339Nigel Graham 2

Participant@nigelgraham2To SillyOld Duffer.

I'm afraid you are reading too much into my motives and needs.

I am trying to design things I can make with my workshop and abilities. I am not in the plans business, nor making brochures. I don't really believe in phrases like "world view", either.

I can see the point of 3D CAD images, and I know CAD anyway requires a new approach of its own, beyond manual draughting.

Vicarious experience at work showed me the advantages of CAD, and I bought TurboCAD. It was the only genuine CAD package available to the amateur at the time – only a few years ago .

I sampled Fusion360 (like Alibre, 3D-model-then-draw) – gritting my teeth at its "in your face" presentation – and AutoCAD 2000 (2D-only I think). SolidWorks is not intended for amateurs. Of various low-budget or "free" CAD packages on-line, those not devoid of engineering-drawing facilities anyway were heavily-stripped "student" or "trial" editions of costly industrial software.

After a monumental struggle I can make good-enough-for-me orthographic drawings, and very, very simple 3D images; but much further is beyond me, including accurately placing and linking multiple 3D elements. (For simple cases and symmetrical elements, I calculate their co-ordinates, but that is slow, error-prone, poor practice.) I will have to live without 3D CAD despite having hoped originally to be able to use that facility.

So I tried Alibre, hoping it might be easier to learn than TurboCAD despite doing the same things. I think I missed an edition of MEW so that won't help, and so far only have the scribing-block base from Part 1 of the series. Given all this, it is not logical to start completely anew on a very different make of CAD with a 3D-first approach.

14 March 2019 at 14:01 #400354Nigel Graham 2

Participant@nigelgraham2JasonB

According to the e-posted notification you invited me to send an example, but I can't see the invitation here.

Never mind, thank you for the invitation.

I don't know if I can take you up on that, I'm afraid, but the machine I am trying to design is the enclosed, inverted-vertical compound engine for a 4"-scale Hindley steam-wagon.

It took me a long time to find a way to design it, irrespective of how to draw it, with no original drawings known. I have now found a proven miniature engine design as a template for the motion-work's geometry; and have started to draw the assembly and parts.

So far, I have drawn the crankshaft from scratch. I'd already part-machined the cylinders so have drawn them from their measurements, and presently I am designing and drawing the engine case.

Geometrically, so far this is a fairly easy set of rectangles and circles, and all in 2D mode.

I had drawn the crankshaft and even started trying to draw the engine's GA, both in 3D. I found both were long and laborious tasks; but the latter soon proved impossible.

I found out how to place that first version of the shaft on the TurboCAD forum gallery as a first 3D attempt, in outline only. Another user kindly coloured it for me! It looks pretty but that's about all.

As a last straw, after my becoming disheartened by a beautiful Alibre rendering of a marine engine on a recent ME or MEW cover, the TurboCAD User's Forum log-on no longer works, at least from my computer. So far IMSI has been unable to repair it, and it prevents my seeking help.

14 March 2019 at 16:21 #400364 JasonBModerator@jasonb

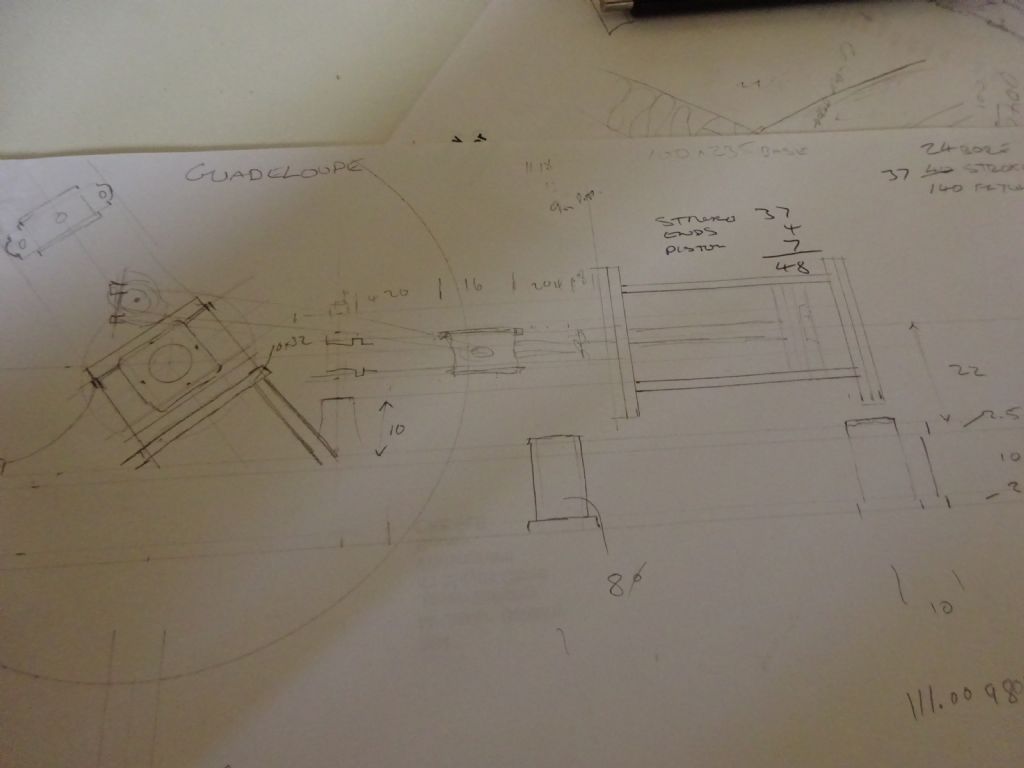

JasonBModerator@jasonbMuch like producing the 2D drawings first attempting a general arrangement as the first step is kind of the opposite to how you use the 3D programs. The following are some examples from an engine that I am working on at the moment for which I only have a couple of photos one of which is this

Started with a basic fag packet hand sketch just to get a few basic proportions

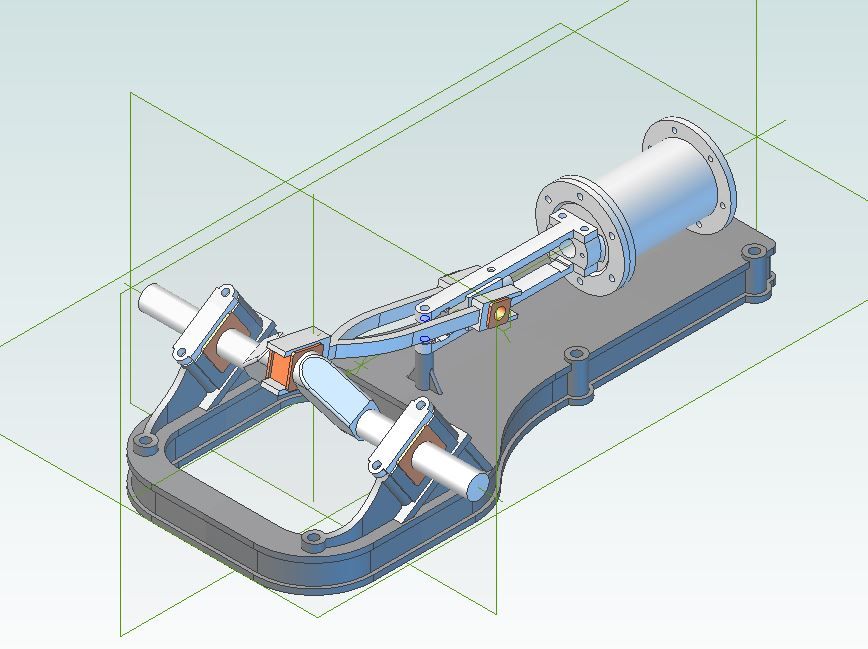

From that I went straight to alibre and started drawing individual parts starting with the base, then as each part is drawn it is placed into a 3D assembly. I will then flit back and forth drawing and adding new parts and tweaking and altering those already sketched to get the fit, proportions etc that I want.

This is the screen shot of what parts I have drawn so far, just basically coloured to indicate material no nee dfor fancy renderings at this stage.

And this is the assembly. What you can't do if you draw it as a set of 2D elevations is rotate the crank and see how the piston rod and cross head move or move the whole assemby around to look at it from any angle. Or if i change any one of those parts it will automatically update the assembly this is the parametric part.

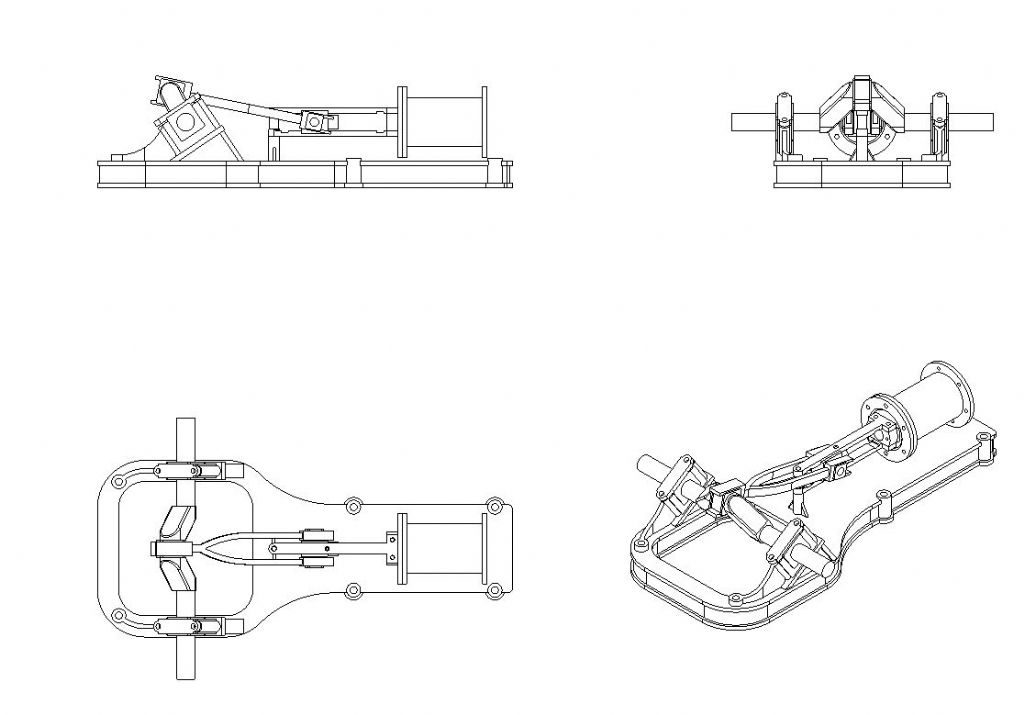

From there it is just a few clicks to produce the GA drawings complete with an isometric and this drawing will automatically update with every change or additional part added.

As I said earlier I'm just a self taught user, not even an engineer and just picked it up by watching a few videos and having a go. That's about 2hrs work at the most on that engine so far

14 March 2019 at 16:24 #400365Anonymous

Interesting debate. I've been using Alibre Design Expert for the last 15 or so years. I'm old enough to have started with drawing boards, pencils of differing widths and a copy of BS308. So I've got substantial 2D experience. Back in the 1990s I started using a simple 2D CAD package – can't remember it's name. But it ran under DOS rather than Windows and was lightning fast. I used it to design parts for racing cars at a time where our draughtsman at work was still using a drawing board. He was cockahoop when a CNC machined box came back with some holes that didn't line up. Turned out the the machinists had made a mistake so he had to grovel. I then graduated to a cut down version of AutoCad, which I didn't get on with. It wasn't anything more than an electronic drawing board, for instance lines didn't snap to the nearest other line, so you had to zoom in to connect and then zoom back out. Hopeless. That was the point at which I bought Alibre. I've not really had any problem using it. Sure there are some quirks and things it doesn't do well. But all real parts are 3D so it's completely natural for me to think in 3D and so it's easy to create a part by extruding and/or cutting. For workshop use I create 2D drawings plus an isometric view of the part. I also make extensive use of assemblies. On my traction engines there are several reasons. One, to account for different size materials due to obsolescene. Two, where I'm changing the design to reflect the original engine, and three because the original drawings are poor and full of fundamental errors that mean parts as drawn would never fit or work.

I find 3D CAD invaluable, it's 2D CAD that's a bit odd. I'm idle and I like parts that I make separately, maybe months apart, to fit together. For that 3D assemblies are crucial to eliminate design errors. After that it comes down to my machining.

In a sense 3D is much older than computers. In the "good" old days things like engine rooms on ships where created as a scale 3D model to establish pipe runs and lengths rather than try and do it as a 2D drawing.

Andrew

Edit: Still got my Rotring pens, although I haven't used them in a month of Sundays.

Edited By Andrew Johnston on 14/03/2019 16:26:43

14 March 2019 at 20:35 #400399Nigel Graham 2

Participant@nigelgraham2A rather unusual engine design there, Jason, with that long bifurcation on the connecting-rod and very wide angles in the crankshaft. What was it (the original)?

Two hours work so far… Ah, but such productivity with shapes like those is possible only with considerable operating skill; beyond my realistically achievable level whether I convert to Alibre or stay with TurboCAD. It would take me two hours to draw even one of the simpler components, and most are by no means straightforward.

I like your system for using colour to signify materials. In fact 19C designers sometimes used colour-wash for a similar purpose, and I think a certain standardising came into use. In some cases, civil-engineers at least also to tinted what might have been contract-negotiating drawings, to make them more eye-catching to the client.

My last attempt at a 3D drawing was of my steam-wagon's cross-head. These will use a siamesed casting pair I chanced upon in one of those boxes of lonely and forlorn castings that appear on model-engineering show trade-stands. A bit big for the scale of my steam-wagon engine but as it's all enclosed and their are no surviving drawings and prototypes, I don't think anyone will quibble!

It's similar to your engine's cross-head but with an internal small-end, and triangular cut-outs at the front and back. I think they were originally for a 7.25"g loco, and narrow-gauge at that. I measured the castings to establish possible machined sizes, then drew it as an extruded outline in thickness, with extruded cuboids subtracted to give the guide-bar channels.

As it happens an Alibre "magazine" has just appeared among my e-posts, containing a short (8 minute) video on common sketch errors. For some reason I couldn't get the separate amp and speakers to work so had to watch in silence (well, to the background of the concert on Radio Three!), but it clearly showed the effects of misclosures not apparent until you magnify the image.

That was one of the first things I learnt eventually on TurboCAD and probably common to any similar make of CAD – that closures have to be pixel-perfect (in fact I think their real definition is finer still; numerical not visual).

I think its point was that in Alibre an extrusion won't work and an un-closed or over-stepped joint is the likely cause. In TurboCAD it might extrude but as a thin-walled polygonal "tube".

I've also found in TC and I imagine you can equally unwittingly do this in Alibre: a lot of editing can leave tiny line fragments hidden under the visible lines; and these fragments play merry hell until you find and exorcise them.

14 March 2019 at 20:47 #400403Nigel Graham 2

Participant@nigelgraham2Andrew Johnston;

Re your, "For workshop use I create 2D drawings plus an isometric view of the part."

From what I saw at work (I retired a couple of years ago) it is common professional practice to put a coloured isometric picture alongside the annotated orthographic views to help the machinist see what he's making.

Having bought both their boring-bar and Worden tool-grinder kits, I see Hemingway Kits uses the same principle.

14 March 2019 at 20:48 #400404 JasonBModerator@jasonb

JasonBModerator@jasonbIts just an engine from a Rum Distillery, may have run a small set of cane crushing rolls or been used for something else.

Alibre will analyse each sketch as you deactivate the sketch and if it finds any problems with the sketch such as you mention above it will list them out and you just click on the item on the list which will then be highlighted red so easy to locate, you may very well have to zoom right in to see the problem but at least you know where to look. From other posts in this thread some users have not had this turned on but it is worth doing so and setting it to come on as default.

14 March 2019 at 21:48 #400411 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattNote that when lining up nodes or shapes or centrelines etc. the cursor changes to show when it has 'snapped' to be perfectly aligned. Watch for this and you will rarely get 'open' shapes.

Neil

14 March 2019 at 21:50 #400412 Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 20:35:55:

Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 20:35:55:I've also found in TC and I imagine you can equally unwittingly do this in Alibre: a lot of editing can leave tiny line fragments hidden under the visible lines; and these fragments play merry hell until you find and exorcise them.

Less of a hazard in Alibre as it doesn't habitually convert curves to multi-segment lines until you export.

Could be an issue with an imported DXF of course.

14 March 2019 at 21:52 #400413 Neil WyattModerator@neilwyattPosted by David Jupp on 14/03/2019 09:34:12:

Neil WyattModerator@neilwyattPosted by David Jupp on 14/03/2019 09:34:12:I'd say that there is significant benefit of using something like Atom3D even if you only want 2D drawings – it's often faster than a pure 2D approach once you get the hang of things, especially if you need cross section views, enlarged detail views, isometrics etc. Also when the design evolves/changes, the 2D drawings update automatically.

The vast majority of commercial users of Alibre produce 2D drawings for manufacture of their designs.

Yes if you are happy working in 3D and then producing a 2D drawing, but I think Nigel wants to work in 2D.

Neil

14 March 2019 at 21:53 #400414 Neil WyattModerator@neilwyattPosted by Steve Skelton 1 on 14/03/2019 10:49:58:

Neil WyattModerator@neilwyattPosted by Steve Skelton 1 on 14/03/2019 10:49:58:Here's my experience for what it's worth.

I tried to use the package based on my AutoCAD 2D experience and fell flat on my face.

I then read the tutorials and had a lightbulb moment.

I found I had to forget everything I had learnt about 2D CAD and drawing board draughting and imagine I was trying to make the item from a solid block or adding to it in a solid block as if I was machining it (or welding on to it). I then found it made sense.

I am not suggesting I am proficient at using the package but if I think in terms of adding or taking away material then I seem to be able to do what I want.

Not sure if others are with this??

Steve

I think you are spot on Steve.

Neil

14 March 2019 at 22:02 #400417 Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 11:02:44:

Neil WyattModerator@neilwyattPosted by Nigel Graham 2 on 14/03/2019 11:02:44:I never reached the advanced levels of "sweeps" and the like, but I found even with those two basic actions the properties of the generated solids and their reactions to editing tools differ markedly, with no clear rhyme, reason, pattern or manual instructions to help you choose the right type where both will give the same figure (mainly cuboids and cylinders). I assumed this will be common to all 3D CAD packages, because they have to perform essentially the same calculations and routines behind the presentation.

:

You still need to understand both Design and CAD. They are separate. The latter is extremely difficult, and exists to express the former as images.

Turbocad has two ways of making 3D from 2D – you can give an object 'thickness', doing this to a circle creates a smooth cylinder. You can also extrude, which leaves the original flat shape and creates a faceted 3D version (typically a circle will have up to 90 facets). These two types do behave differently.

Alibre just has one consistent extrude which does not create a separate, but a smooth one still connected to the original shape, like TC's 'thickness' but more flexible.

MY feeling is that DESIGN is the hard bit and which needs lots of experience. CAD is a lot of unfamiliar things at first but the steep learning curve soon flattens out.

If you have missed parts of the series you can get back issues at mags-uk plus Mintronics are looking at producing a PDF version of the series.

Sorry to harp on, but I suspect that if you were asking 'how do I do this?' rather than 'why should I bother to learn this?' we would have you happily using Alibre by now.

Neil

Edited By Neil Wyatt on 14/03/2019 22:05:12

14 March 2019 at 23:01 #400430Nigel Graham 2

Participant@nigelgraham2Thank you Neil. I would ask if I do convert to Alibre and need help.

I need decide whether to continue to attempt to learn CAD or give up; then choose whether to stay with TurboCAD or to convert to Alibre.

TurboCAD has a third way to generate solids: "Primitives", a few common solids like cuboids and cylinders you set to your own dimensions. These too, have their own characteristics.

I think the relative difficulty of Design and CAD is in favour of the design to start with but I understand your point.

I see using CAD or indeed manual drawing means acquiring a set of fixed skills, as tools to perform a project. Those tools change only in minor details; but the project is the real variable. In model-engineering, it can be anything from a simple machine-tool attachment to a showmen's road-locomotive or radial aero-engine.

However, I find CAD far harder to learn than I had envisaged, irrespective of what I design; and I can learn any difficult subject only to a random, unpredictable but rigid level. I abandoned CAD for about 6 months within a year of buying it; but having tried again I think I am near or even on my level for it.

15 March 2019 at 10:51 #400491John Davies 6

Participant@johndavies6Am just starting. Drawing the 25 mm circle went OK; but after deactivating and going to Extrude, the circle disappeared from the screen. and the Extrude dialogue box "enter box" was greyed out. I am sure there is a simple explanation; but I have not been able to find it yet.

Be very grateful for any help. John

Edited By Neil Wyatt on 01/05/2019 13:54:51

15 March 2019 at 11:10 #400495David Jupp

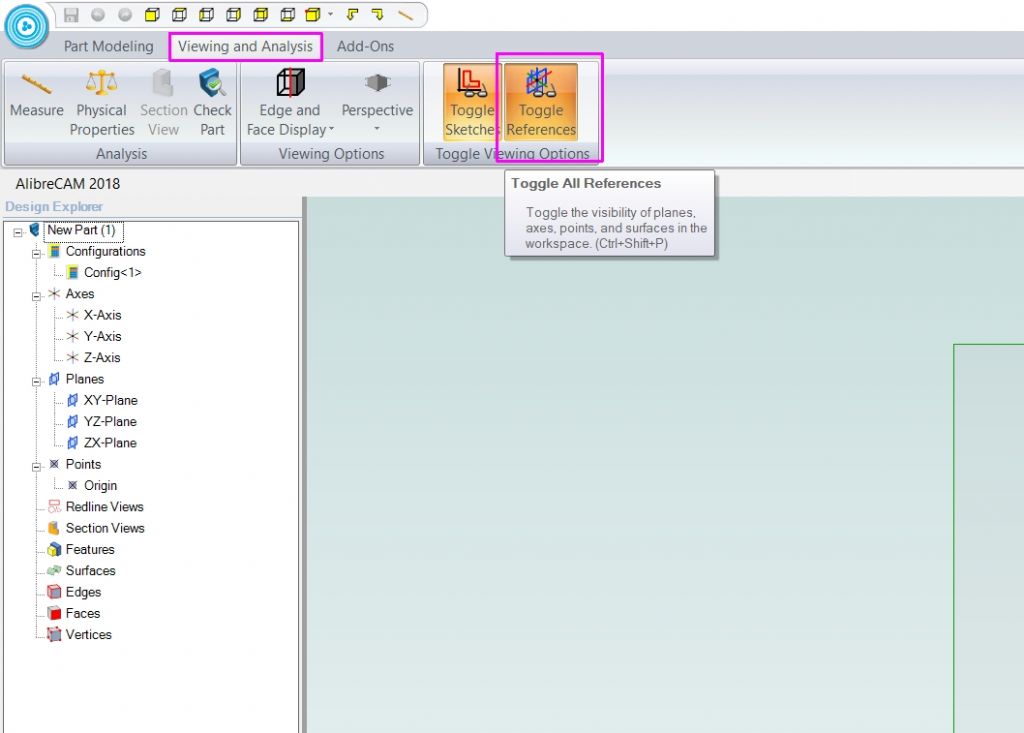

Participant@davidjupp51506Circle disappearing – you may have 'sketch visibility' toggled off. There's a button for that on the Viewing & Analysis tab of the Ribbon, or try key combination Ctrl+Shift+K to toggle it. Sketch visibility is not required to be on, it's a preference choice.

Enter box greyed out for Extrude dialogue – some key information is missing – is the 'Sketch' field populated? If not clik in it, then click on the sketch to be used (in Design Explorer).

Edited By Neil Wyatt on 01/05/2019 13:54:57

15 March 2019 at 11:13 #400496Anonymous

Posted by Nigel Graham 2 on 14/03/2019 20:47:27:From what I saw at work (I retired a couple of years ago) it is common professional practice to put a coloured isometric picture alongside the annotated orthographic views to help the machinist see what he's making.

I don't colour or shade the isometric view. The isometric view is helpful to give a quick overview of the part without having to interpret the 2D views. It is also useful as a sanity check for asymmetric parts to ensure you don't drill, or countersink, for example on the wrong side.

Andrew

Anecdote: In my O-level metalwork practical I countersunk some holes on the wrong side of a part. Fortunately the part was then riveted to another part so the boo-boo was hidden, and I passed metalwork with grade 1. Which was pretty much the highlight of my school career.

15 March 2019 at 11:19 #400500 JasonBModerator@jasonb

JasonBModerator@jasonbYou want the one on the left of the pink box "toggle sketches"

Edited By JasonB on 15/03/2019 11:20:00

Edited By Neil Wyatt on 01/05/2019 13:55:05

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Model Engineer & Workshop › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Forthcoming improvements in White LEDs

Started by:

Michael Gilligan

in: Electronics in the Workshop

Michael Gilligan

in: Electronics in the Workshop

- 2

- 2

-

12 March 2025 at 18:53

Grizzly bear

-

Continuing the Television theme …

1

2

Started by:

Michael Gilligan

in: Electronics in the Workshop

Michael Gilligan

in: Electronics in the Workshop

- 13

- 27

-

12 March 2025 at 18:49

Robert Atkinson 2

Robert Atkinson 2

-

FB2 Clone – aligning the column

Started by:

Diogenes in: Manual machine tools

- 11

- 24

-

12 March 2025 at 17:53

Graham Meek

-

Whistling TV

Started by:

Speedy Builder5 in: Electronics in the Workshop

- 6

- 9

-

12 March 2025 at 17:45

Speedy Builder5

-

Farm Boy

1

2

3

4

Started by:

Dalboy in: I/C Engines

- 15

- 91

-

12 March 2025 at 17:07

Dalboy

-

3/16″ lathe chuck key wanted

Started by:

Wink Hackman in: Workshop Tools and Tooling

- 10

- 13

-

12 March 2025 at 16:37

DC31k

-

Identify

Started by:

melvsals in: Introduce Yourself – New members start here!

- 4

- 4

-

12 March 2025 at 15:08

Andrew Tinsley

-

Su251-53

Started by:

parovoz in: Locomotives

- 8

- 14

-

12 March 2025 at 15:04

Nigel Graham 2

-

Lathe cutting a taper

Started by:

Chris Mate in: Beginners questions

- 9

- 13

-

12 March 2025 at 14:53

Clive Foster

-

Boiler Examinations: 7-yearly External Query

Started by:

Nigel Graham 2 in: Traction engines

- 4

- 6

-

12 March 2025 at 14:30

Nigel Graham 2

-

NEW LOOK – Model Engineer & Workshop

1

2

…

6

7

Started by:

sohara in: Model Engineer & Workshop

- 55

- 175

-

12 March 2025 at 13:13

parovoz

-

Where/How will you be watching ?

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 2

- 2

-

12 March 2025 at 10:43

Nicholas Farr

Nicholas Farr

-

Mobile workshop

Started by:

Sonic Escape

in: The Tea Room

Sonic Escape

in: The Tea Room

- 12

- 23

-

12 March 2025 at 06:50

Diogenes

-

Myford 254s

Started by:

dt-tech in: Manual machine tools

- 3

- 3

-

12 March 2025 at 04:50

Howard Lewis

-

Another Fobco Chuck

Started by:

spencerd72 in: Workshop Tools and Tooling

- 5

- 9

-

11 March 2025 at 21:54

Chris Crew

-

Morse Key

Started by:

Steve Withnell in: Work In Progress and completed items

- 7

- 8

-

11 March 2025 at 21:27

rjenkinsgb

-

Firth Valve Gear

Started by:

Andy Stopford in: Traction engines

- 6

- 13

-

11 March 2025 at 21:07

Andy Stopford

-

Just got my first loco – advice on consumables/accessories

Started by:

Beardy Mike in: Beginners questions

- 6

- 9

-

11 March 2025 at 21:02

noel shelley

-

Readability / clarity in new combined magazine

Started by:

Trevor Gale in: Model Engineer & Workshop

- 7

- 10

-

11 March 2025 at 20:29

Clive Foster

-

Chips away! First cut

Started by:

Dave S in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 3

- 3

-

11 March 2025 at 20:19

Michael Gilligan

Michael Gilligan

-

Cheap MMA inverter (aka stick welder)?

Started by:

Fulmen

in: Workshop Tools and Tooling

Fulmen

in: Workshop Tools and Tooling

- 4

- 8

-

11 March 2025 at 18:37

Fulmen

Fulmen

-

Model steam marine boiler

Started by:

raindancer in: Help and Assistance! (Offered or Wanted)

- 4

- 7

-

11 March 2025 at 17:32

raindancer

-

Discussion on the Future Direction of Model Engineer and Workshop

1

2

…

11

12

Started by:

Neil Wyatt

in: Model Engineer.

Neil Wyatt

in: Model Engineer.

- 72

- 295

-

11 March 2025 at 16:27

David Standing 1

-

Mystery casting

Started by:

Phill Spowart in: General Questions

- 4

- 4

-

11 March 2025 at 16:16

bernard towers

-

Fritz Werner Universal Mill

Started by:

Bob in: Manual machine tools

- 4

- 11

-

11 March 2025 at 14:58

sjoerd981

-

Forthcoming improvements in White LEDs

-