Posted by John Hinkley on 25/11/2018 08:38:56:

Once I've put the conrods and pistons "in", I'll investigate the motion system.

John

John, I would suggest making a separate assembly of the Conrod, cap, any bearing shells and wrist pin. You can this bring this assembly into your main one which makes life a bit easier.

You may also find it helps to set the crankcase to semi transparent so it is easier to see what is going on.

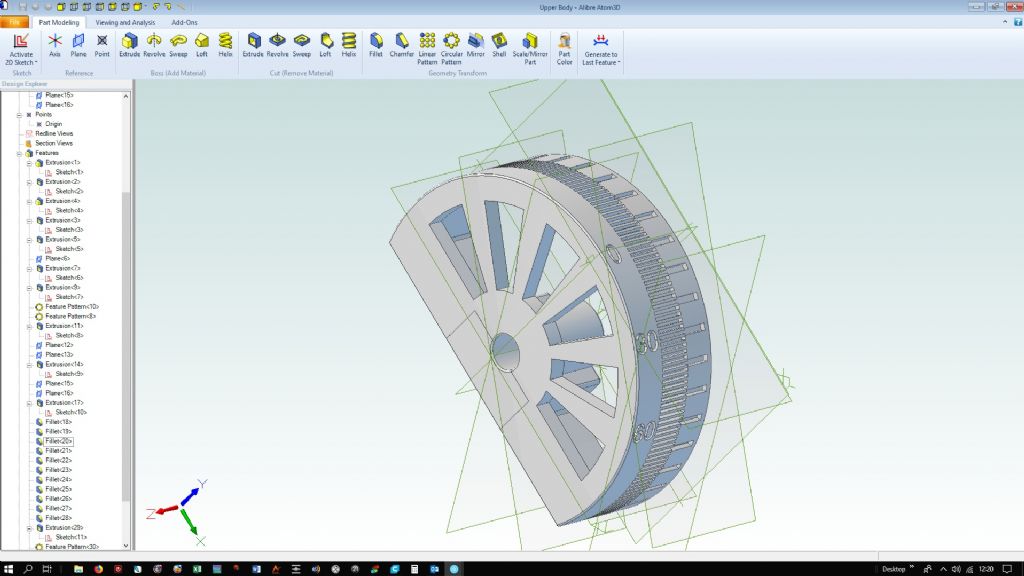

One other general comment for anyone is that if you go back to alter one of the sketches that make up a part do make sure you click on the "generate to last feature" before saving as the part will get saved at the point where that sketch is down the list on the left. You won't loose any subsequent sketches but the actions won't be shown.

This can also be taken advantage of by putting all of your cosmetic actions such as fillets, chamfers, visual threads etc at the end so they can be left off when doing assemblies or drawings to make files load faster and keep the drawings clearer.

It is also possible to "suppress" any item which removes it from the model but still has it in the list, just right click in the list and click suppress.

Ady1.

Ady1.