For those with DRO, NO problem, with Top or Cross slides.

Filters for cameras are usuall 0.75mm pitch threads.

For a mini lathe (Seig C3?) the Leadscrew is 1.5mm pitch, and a Handwheel with 60 graduations, provides resolution of 0.025mm /division, or 0.00098425 inch/division in old money. (Personally the "425" bit won't matter to me too much, the "98" will be hard enough to handle) .

BA is really a metric system, although perhaps some oddball pitches, so better produced with Taps and Dies.

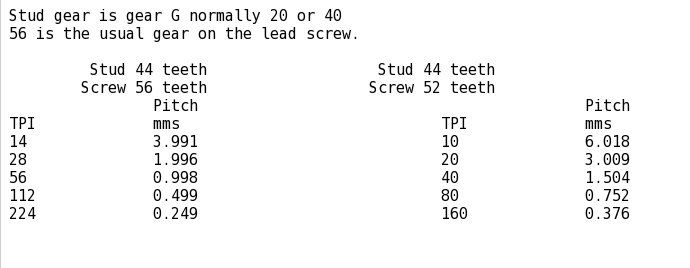

And, Yes, I have a 63T gear, but not yet used it. On machines with Norton boxes, such as Warco BH600, Chester Craftsman, or E T R BL12/24 the 120/127 compound gear allows fairly quick changeovers.

If all you normally screwcut is Metric, set up for metric and carry on. If you think that one day you MIGHT want to screwcut Imperial threads, buy a 63T gear "Just in case, it comes in handy one day" I did, still unused, but upto 1/2" I would use Taps and Dies for BA, BSW, BSF, BSB, BSP, UNC, UNF or ME.

I do have a very few Taps for Metric Fine, but unused (The "might come in handy one day" syndrome)

Have never needed to deal with electrical conduit, Cycle threads, or UNEF, and hope to keep it that way!

Howard

MW.