Posted by Pero on 21/01/2023 03:48:00:

What on earth is Schlesinger doing using a spirit level? I thought that was verboten!

I find a pair of winding sticks ( as taught by my woodworking instructor many decades ago.) to be much more satisfactory. For our purposes these can be as simple as two good quality rulers.

…

Pero

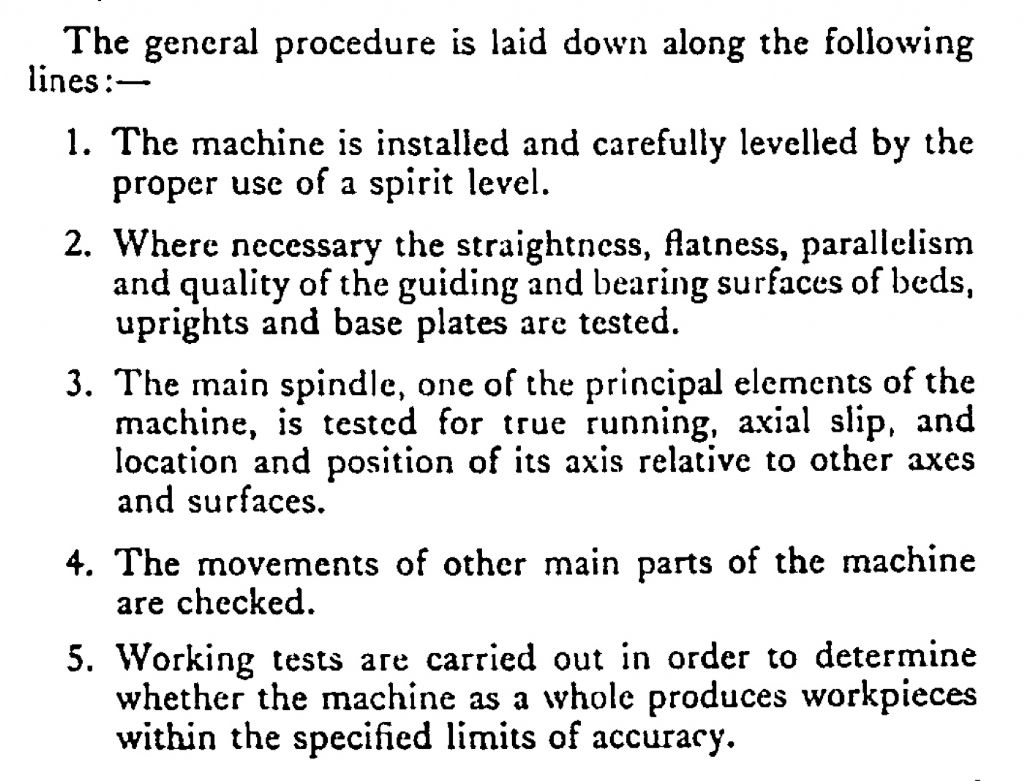

This is confusing two separate steps.

Winding sticks are one way of tackling Step 2, not a substitute for Step 1.

My feeling is two different reasons for levelling have become intertwined and this causes confusion.

Schlesinger's step 1 is basic engineering best practice. Lathes are designed to operate upright on a flat floor. Consider the lathe as a bridge or girder rather than a machine tool. Its substantial weight is best managed by taking it straight down to ground. If the weight isn't taken straight to ground the frame is likely to twist and the machine might topple over. Builders level and use plumb lines to ensure their walls are true for this reason. Failing to level a tower block or even a garden wall is incompetent. Perhaps less obviously levelling is also necessary when installing any kind of large machine, and the need for level accuracy becomes more important as size and weight rises.

New machines were set-up level by the maker, and could be expected to perform properly if installed level in the same way by the customer. Stage 1 is applied first to the floor, then the stand, and finally to the lathe. Schlesinger emphasizes levelling because he was a professional engineer concerned with getting the best out of large machines, not the tiddlers we own!

Considered as bridges, mini- and other small lathes are stubby and stiff compared with Myfords. They can be plonked on any reasonably flat surface without twisting the bed. Levelling these likely to be a waste of time.

Considered as bridges, Myfords are bendy. Their beds twist making it necessary to take reasonable care installing them. Having a bendy bed isn't all bad, because they can be deliberately bent to improve alignment.

Moving on to Stage 2, all big lathes should be considered bendy. Even monster machines sag under their own weight, and more when loaded. A stiff lathe lightly loaded with small work may be fine, but not if asked to turn something heavy. How much each machine bends varies, but it's best to install on a stiff straight stand supported by a firm flat floor.

One way of correcting alignment in Stage 2 is with a sensitive engineering spirit level, another is the 'Rollies Dad' method, and I suppose 'Winding-sticks' would get close too, at least with a flat-bed lathe. How accurate is aligning by straight-edge and does it work on a prismatic bed? I don't know.

Once a lathe is installed in a fixed position, it doesn't need to be level to turn straight. Within reason they work tilted on ships or in outer-space.

So two related but different reasons for levelling lathes, both potentially optional. It's confusing, especially when 'levelling' is used to mean 'aligning'.

Dave

Edited By SillyOldDuffer on 21/01/2023 13:39:37

Niels Abildgaard.

![wp_20230122_001[1].jpg wp_20230122_001[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/918586.jpg)

![wp_20230122_002[1].jpg wp_20230122_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/918587.jpg)