Posted by Rockingdodge on 03/07/2023 17:33:45:

…

The one thing that confuses me is the difference between the safety earth and shielding earth … then surely earth is earth and thus the mains cable carries the difinitive earth?

Earthing is complicated and done for different reasons.

- In an electrical supply system, generators produce a 3-phase output which is distributed over three wires, with no earth. 3-phase is inconvenient for most domestic purposes: a 3-phase light bulb or TV would be bonkers. Also more dangerous in a home than need be because all three wires are 'hot'. Instead, 3-phase goes to a sub-station, where a transformer outputs 3 single-phase supplies, each of which serves different properties. Single phase has two wires, both of which would be 'hot', except one is earthed by the supplier at the transformer. Thus homes get two wires, Line (or Live), and Neutral. Although Neutral carries current, it's safe because it and anyone likely to touch it are all at earth potential. Also, each house has it's own separate earth (details vary). The house earth protects against failure of the supplier earth and also allows anything in the building that might accidentally become hot to be grounded. So if a bare Live wire accidentally touches a hot-water pipe, fuses blow rather than allow the plumbing to become shock hazard. House earths are designed and implemented in a particular way, affordably fit for purpose, but not suitable for everything.

- The movement of clouds often charges them with static electricity. The charge can become enormous because they're big and well insulated. Eventually the potential difference between cloud and ground breaks the insulator (air), and a lightning bolt jumps, often via tall objects like chimneys and towers. Several hundred amps flow causing considerable explosive damage. Bricks and mortar are blown apart when moisture inside flashes into steam; wood catches fire; and people are electrocuted or hurt by flying debris. The chance of a strike is reduced by fitting a lightning conductor, the wire and earth of which are much beefier than an electrical safety earth, which is inadequate for lightening protection. To avoid a lightening strike getting into a building's electrical system, lightening protection and supply safety earths are not connected together.

- In a long or medium wave radio transmitter, the planet acts as one side of a dipole antenna, BBC R4 LW transmits on 1500 metres. An efficient dipole at 198kHz would be 750 metres high. Instead, the planet is electrically balanced against a smaller aerial wire. Efficiency depends on achieving a very good earth at 198kHz, miles of wire spread over a few hundred acres. Although considerably more elaborate than a lightening earth, it isn't a good lightening earth, so at least one of those is required as well. Plus an electrical safety earth for the transmitter building. None of these earths are connected together.

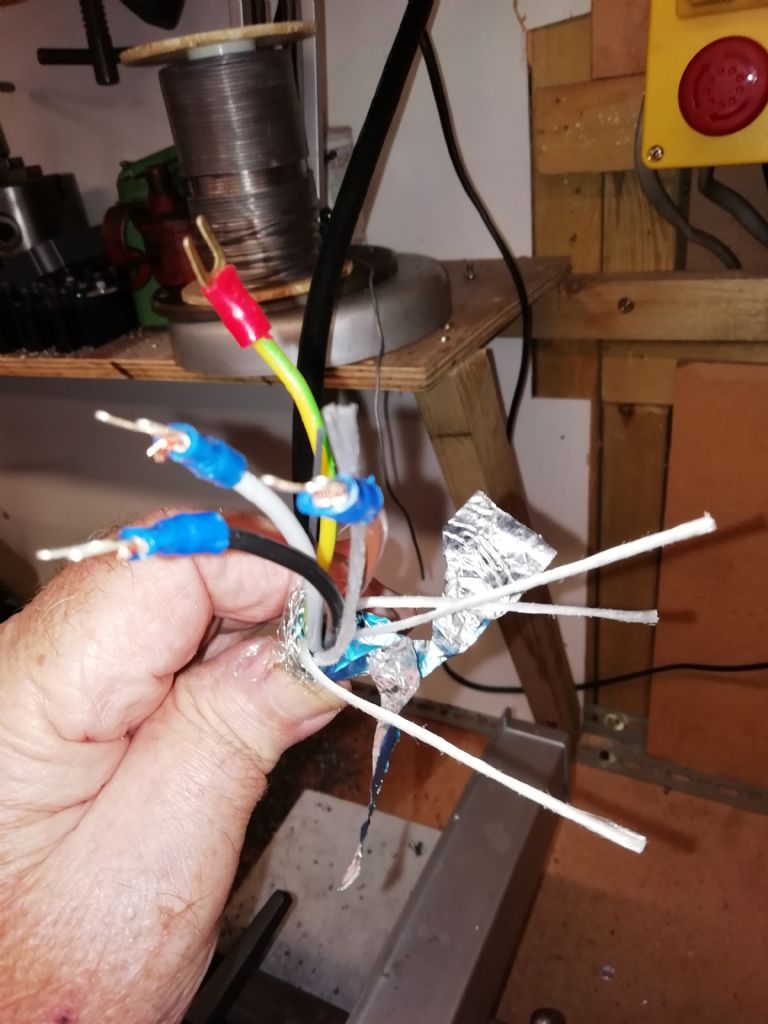

EMC is yet another case, albeit closer to the radio example than the others. EMC uses shielding to stop inductive, capacitive, and electromagnetic coupling. As the coupling is usually electrically unbalanced, shielding won't be effective unless it too is earthed. And because shielding often consists of bare metal, it's necessary to ground it for electrical safety reasons. Unfortunately electrical safety earths are rarely good Radio earths. One problem is the earth wire on the lathe connects through a longish lead to a power socket. Then the supply earth wire runs around the building until it reaches the Consumer Unit, probably tens of metres away. From there, it's connected to the supply earth, probably some distance away. To a high frequency wave, all this wire looks more like an antenna or transmission system than an earth. It becomes a good way of transferring EMC further, not a way of stopping it. And when it gets to the actual safety earth, perhaps just a few feet of copper rod banged into the ground, 1ohm at 50Hz can behave like thousands of ohms at Radio Frequency.

Ideally, there should be an EMC earth near the VFD. However, as this could be difficult, expensive, or break electrical safety rules, it's usual to use the electrical safety earth and hope it will do. The safety earth may need help! I see Robert supplied a Ferrite: I have no experience with these and VFD interference, but in principle they 'choke' wires, making it hard for EMC to get further whilst having no effect on normal function. Not as effective as a properly designed filter, but might be good enough, especially in conjunction with other measures, In that vein, experiment with earth points on the machine. Sometimes adding another earth point will successfully short out the EMC. In other cases, a new earth point creates a loop that makes it worse. Finding the best combination can be hard work, and maybe there isn't one.

Professionals approach the problem rather differently. When money is no object, EMC is conquered simply by following best practice from end to end. Everything is comprehensively shielded and filtered to stop electrical muck getting in or out. Not cheap…

Dave

Robert Atkinson 2.

Robert Atkinson 2.