Posted by Gene Pavlovsky on 05/05/2020 08:12:57:

…

I did read a couple of lathe books and a lot of articles, so I have basic understanding of the terms and processes (and kinds of tools available), but no hands-on lathe experience whatsoever.

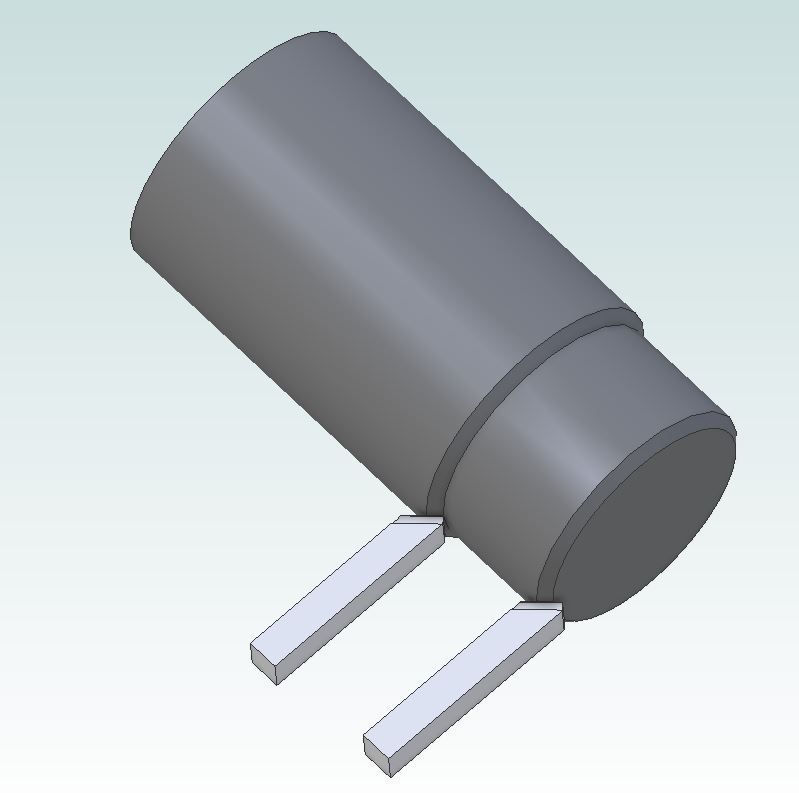

My lathe came with some 20+ carbide-tipped tools (brazed tips, not indexable), and I was recommended by an acquaintance to not bother with either these or HSS tooling, and just get a set of indexable carbide tools.

…even those who use indexable carbide tools, still have to sometimes grind HSS tools for special occasions. I think I will start with trying to grind a general purpose RH tool. Any other tools I should look into making next?

Well, I'm going to recommend tackling the 'no hands-on lathe experience whatsoever' problem, before moving on to grinding HSS.

For a beginner the advantage of a set like your is that the tools are sharp and correctly shaped. Self-taught beginners face a steep learning curve:

- Understanding the machine's controls, adjustments and limitations (which might include faults)

- Selecting an appropriate tool shape and setting its cutting point to centre height while minimising overhang.

- Work-holding: short stubby is easy, long slender is hard, as are odd unbalanced shapes.

- Understanding materials. Metals vary considerably and many are downright difficult to machine.

- Finding a reasonable combination of rpm, feed-rate, and depth-of-cut for the job in hand.

As all of these can result in disappointing results, it's best to eliminate as many unknowns as possible during the learning phase. So, don't start with home-ground HSS, have a go with the left and right hand cranked knives. The RH knife is good for facing, LH for most ordinary turning. Of the set, these are likely to be most popular. Get hold of a machinable Aluminium Alloy or Brass Rod about 20 – 30mm diameter and do some experimental turning and facing. Not scrap!!! Steel can be used, but keep to EN1A / 1113, ideally Leaded. It it doesn't go well, time to ask why, but at least you know the tool is good.

Not unknown for inexperienced chaps to assume their new machine is carp, and send it back or dismantle it, when the real problem is they are untrained, unpractised rookies. When I started with a mini-lathe I suffered months of poor results because my scrap box happened to be full of inappropriate metals.

Once the beginner gets reasonable results, or understands what's wrong, then it's time to branch out. If a home-ground LH knife fails to cut properly when the set version does, then you know it's the home grind that's wrong. The set LH & RH knives are easy to sharpen – a simple straight grind across the end face.

HSS is your oyster once the grinding wheel is mastered! Any tool shape you like – see Mick B1's examples earlier in the post. But beware of chaps claiming grinding is easy! Like anything else, some take to grinding like a duck to water. Others find it difficult; after a lot of practice I get acceptable results, but I'm far from Mick's standard. The only way to find out is to try it!

Re mystery tools, the very sharp one is a finishing tool. The Chamfer/Corner tool is dual-purpose – held straight it cuts chamfers, held at an angle it reaches into corners. In practice, the operator is allowed to improvise, for example I've used the sharp finish tool to botch a 55° thread. Mick goes even further – having found a set didn't meet his needs, he reground the tools into other shapes. It's allowed!

For what it's worth, I prefer the convenience of carbide inserts to HSS but it's not a religion. I switch between HSS and carbide happily, depending on the job. I agree with your advisor's recommendation to avoided brazed carbide. The sets often arrive unsharpened, and they require a special grinding wheel. I'm sure brazed carbide is useful for certain work, but if I'm grinding for a precision job I'd rather use HSS, otherwise inserts are quick, easy and hard working.

Have fun!

Dave

JasonB.

JasonB.

. I was under the impression that most ordinary turning is done from right to left (towards the chuck), so wouldn't that be a RH knife

. I was under the impression that most ordinary turning is done from right to left (towards the chuck), so wouldn't that be a RH knife