In these days of relatively inexpensive dial gauges and indicators it's surely more sensible to make a bench "tool setter" device to directly measure the actual height of the cutting edge and calculate the shim thickness needed.

Fit a dial gauge with an elephants foot, attach to a suitable upstand fixed to an adequately flat base and the worlds your mollusc. I imagine the colour coded plastic shim sheets will be up to the deed on our smaller machines so keeping track of what shims you have becomes easy.

Not forgetting some thicker ones if you need to build up seriously for smaller tooling.

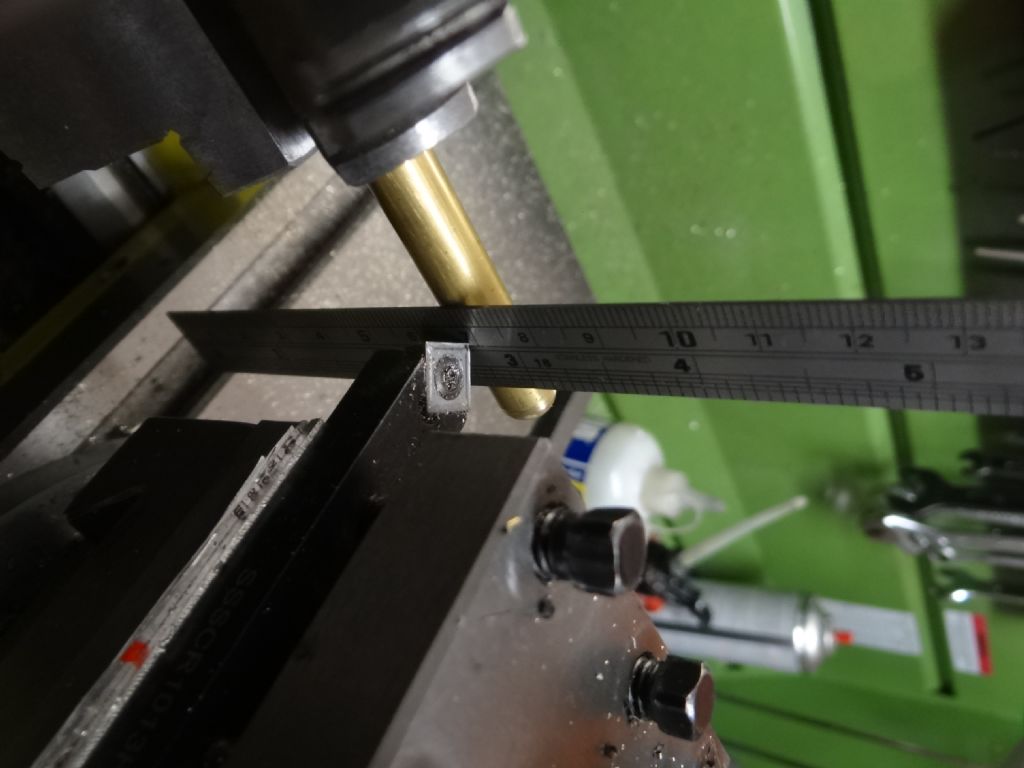

That said I prefer sharp internal corner angle, whether bought (alloy extrusion is usually good) or welded up, for rough setting of undersize tooling as the upright side helps keep the tooling centred under the clamp bolts. A trick that works just as well with QC systems like my Dicksons.

The more economically minded can do adequately well with a long lever pivoted close to the short end and a ruler on the long end. If you can read 1 mm a 1 to 10 ratio gives 0.1 mm, 4 thou, resolution. Well beyond what can reasonably achieved with a centre height gauge or Dave's method. Which latter I loathe in principle because its accuracy decrease as the stock gets larger. Around 1" or 25 mm diameter is the easily useful limit. Its ability wreck a sharp edge being merely a side benefit!

For insert tooling it's just a pure mathematical exercise reading off holder and insert dimensions from the data sheet to work out the shims needed. Tolerances for any half decent system are way better than you can achieve with a centre gauge.

For me the most convenient type of centre height gauge is the optical style. Basically just a thick piece of perspex held up right by a suitable base with a line scribed at centre height on both sides. If the two lines and the tool tip set nearly touching the blade eye up coincident the tool is on centre height. The coincidence principle means it can be viewed from a distance without noticeable error. Shove a mirror on the back at 45° and you can look down on it rather than along which is sometimes better.

Just the thing for setting QC systems.

Probably the easiest type to make too. So nice when really easy and really good come in the same box.

Clive

Clive Foster.