Thanks for the responses, guys.

Old Mart I *think* that this is what I was hoping would work, but as Huub says, it's a bit of a pain to do. I will give that a go, though.

Andy – that was very interesting. Did you check the trueness of the lathe after the work? I see that you'd checked that it was the same after bolting as before, but that assumes that the bed was in true to start with. That's something I will have to consider, probably later as I don't have the stock for that and my welding skills are … dubious!

In passing, my parting off has been much better since I changed the guides for the cross-slide under the bed. Teh replacements are brass and somewhat heavier than the original bars. I found this on a you-tube video, but can't recall which one other than that the author had a distinctive nasal voice. 20mm mild steel seems quite reliable these days even at higher speeds. Having said that sometimes it doesn't work for no apparent reason!

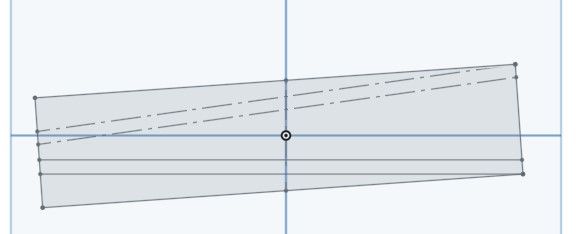

Chris, If I've understood your question correctly, the diagram below might help..

The angled rectangle is the bar in a chuck which leans away from the operator. Left hand side is the chuck end. Note that the chuck is in line with the spindle and the bar rotates around its axis.

the bottom horizontal lines represent the travel of the cutter. the lower one is the outside, then inner the bore.

The dotted lines are what the travel would be on the other side of the bar..It's a bit hard to see, but if you tilt your head so that the bar is horizontal you will see what I mean.

Thus the part near the chuck is narrower (inside and out) than the end.

Hope that makes sense!

Iain

Howard Lewis.

![wp_20200310_004[1].jpg wp_20200310_004[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/859604.jpg)