Posted by Plasma on 11/03/2019 06:46:48:

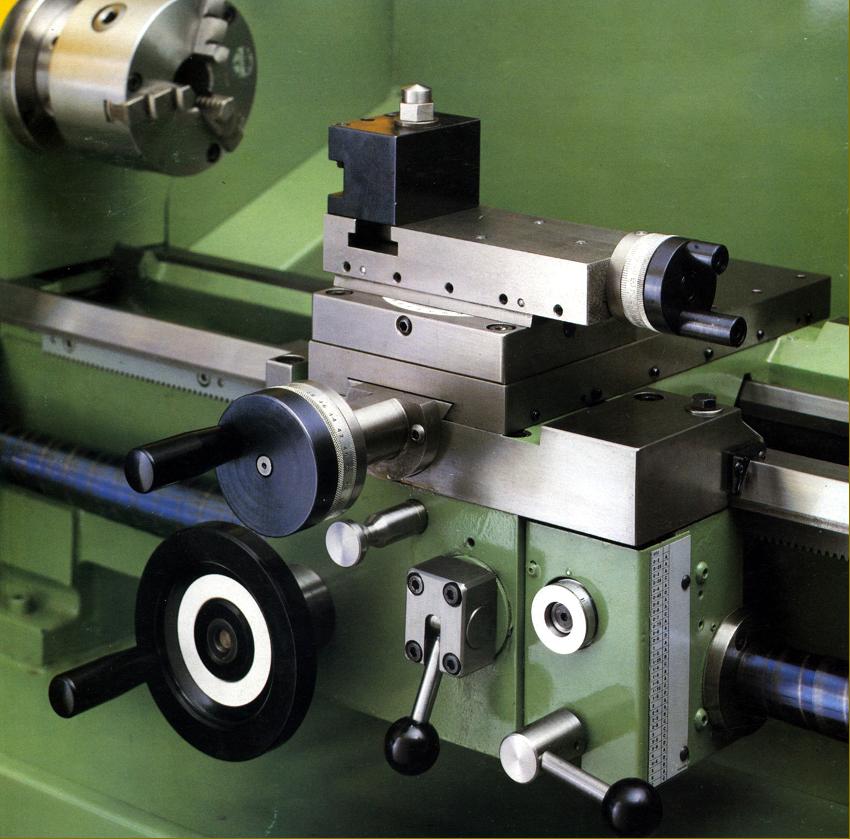

Sparey shows a home made sprung threading tool bit holder which is supposed to do a sterling job due to the flex in the neck allowing for fine cuts by repeating passes with no infeed. I just wondered if anyone had seen a commercial equivalent.

Sparey has one fault – he wrote 70 years ago! Although most of his advice remains fresh, his books have a few obsolete ideas, and – of course – he doesn't cover technology that became available after his time, notably carbide inserts.

Hand grinding a 60° or 55° pointy threading tool in HSS requires practice and not everyone is good at grinding. Give it a try, you can get started making external threads with quite a poor tool shape. The result may not be beautiful, or strong, or a tight fit, but they do work. Once you've made a few threads you can concentrate on improving them, most likely with better grinding and lathe technique. I don't think many people bother with spring holders, but they do pop up second-hand or you could make one.

Personally I find it easier to use indexed thread inserts, these cut properly shaped thread profiles, and can be changed quickly without interrupting my workflow if the point gets damaged.

Deciding between HSS and Carbide depends on your interests, goals and equipment. Some love HSS, others swear by inserts. As is the way with hobbies, I've maximised the cost by insisting on both…

Dave

Hopper.