There are some simple things that are better made than bought such as centre punches and drifts for knocking dowels out of things. Many items like that are made of air hardening steels these days and don't really measure up to the old way – hardened and tempered steels. Silver steel is suitable and easy to get. For slotted screws a hollow ground blade increases the grip by an extra ordinary amount. The rad of a 6in or 8in grinding wheel is about right for the hollow grinding.

A lathe type centre finder is can be useful for face plate work also 4 jaw at times. Pictures can be found on the web but they benefit from having stiff spring loading built in as well. Around 12in long over all is a decent length for one with say a 4in section with the female centre hole to hold the spring.

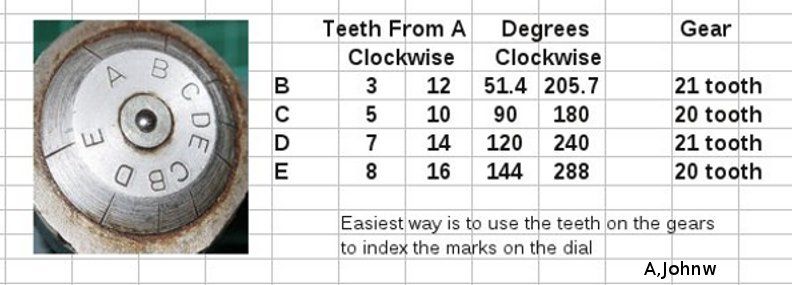

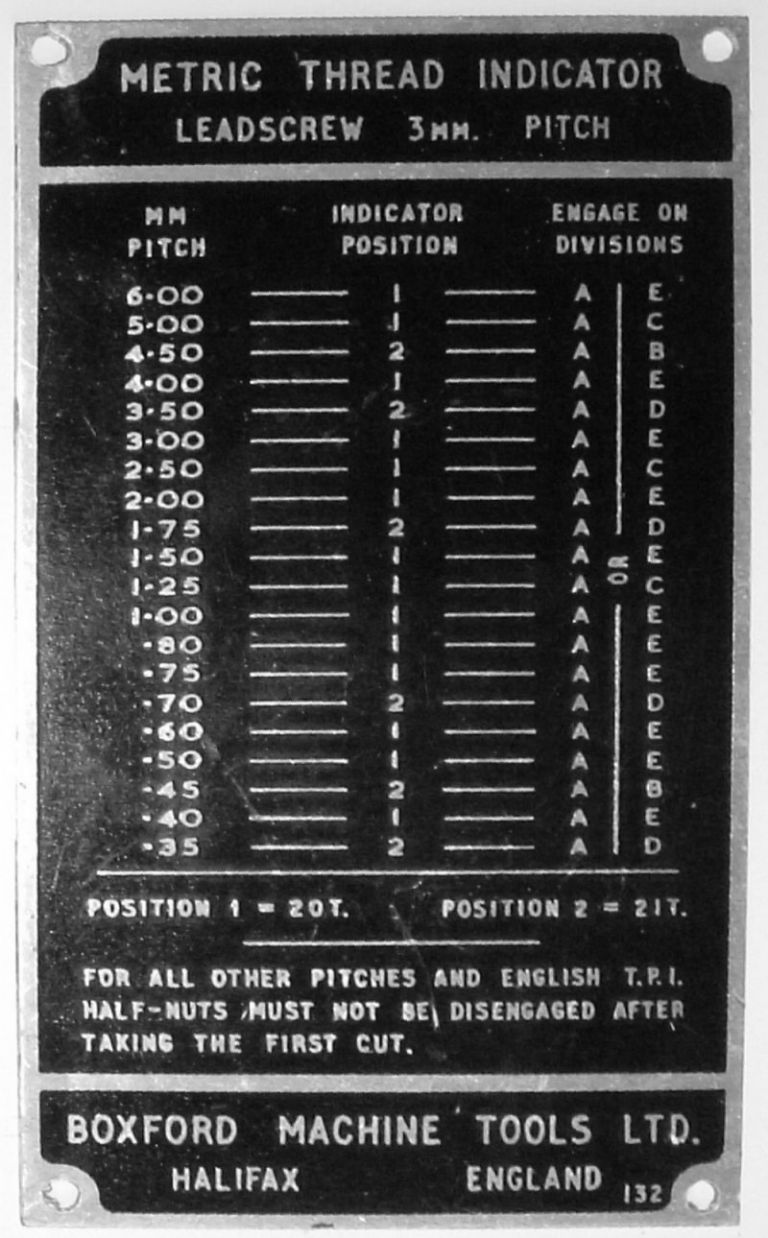

If you envisage fitting your own chucks a very precise dummy spindle nose is very useful. If the Viceroy is the same as the Boxford you need to cut the flanks of the thread correctly to size but omit the rounded end – normal way of screw cutting on a lathe. This means that the OD is undersized which help get the register correct in cases where the lathe doesn't have a different diameter register. A very short section of the register can be turned under size – say by 0.010in to help use it as a plug gauge when making back plates. The threads in the back plate are best cut entirely with a chaser. They crop up on Ebay regularly. Not sure how you will get on doing this on a metric lathe as the spindle might still be imperial. In that case you will probably have to reverse the lathe at the end of each cut. Best way to do that is often described on the web when metric threads are cut on an imperial lathe. It uses a screw cutting indicator in a particular way. Disengage, turn off, reverse and re engage when the indicator is where it was when disengaged.

You might find that College engineering produce a casting suitable for a Boxford/Viceroy face plate. They did do an excellent rotary table kit but unfortunately it was slimmed down to suit the gap in a Myford bed. Still better than most but not sure if they do it any more.

If I want a keyway in a bore I use a slotting attachment. They do the casting for these as well but as it's for a Myford tt needs packing up to the centre height.

Lots an lots of things can be made but some of the more ambitious ones such as a dividing head do need a T slotted cross slide. This chap can help with that if the machine lacks one

http://www.latheparts.co.uk/

He's always busy and can be hard to get hold of.

John

–

Gareth Johnston.