I have been working quite some hours to make a useable M50*1.5 ER40 thread.

Spindle- material was a cheap end of bar offcut and soft and like water pipe with inclusions of old scrap that is hard as tool steel.

It was quite a learning.The motor torque and power is more than enough for normal cutting and when it hits on of the hard spots spindle stops immidiately and belt slips.

Stopped motor and applied some brute torque with a C spanner in the spindle holes close to headstock.

One time the motor had not stopped (very low noise) and when I was through the hard spot,my guardian angle did her work..

Very ,very nasty.

Future considerations on motor power and rev will exclude motor powered single point screw-cutting.

A handle screwed on end of spindle is the way to go for old fools.

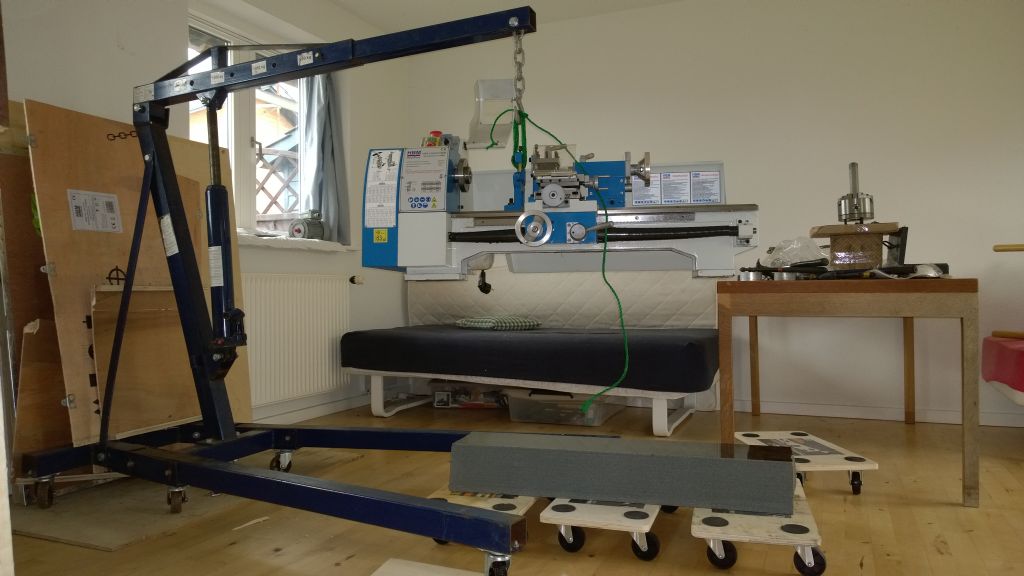

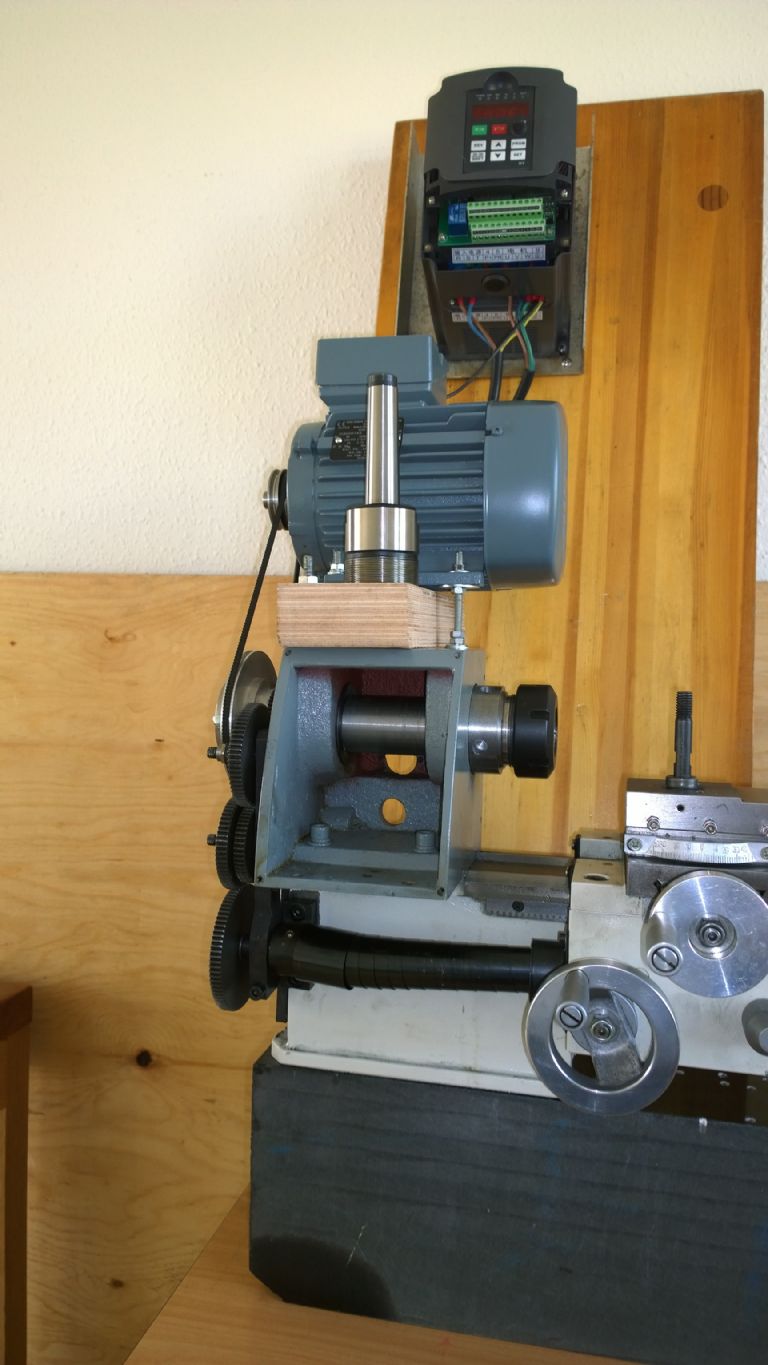

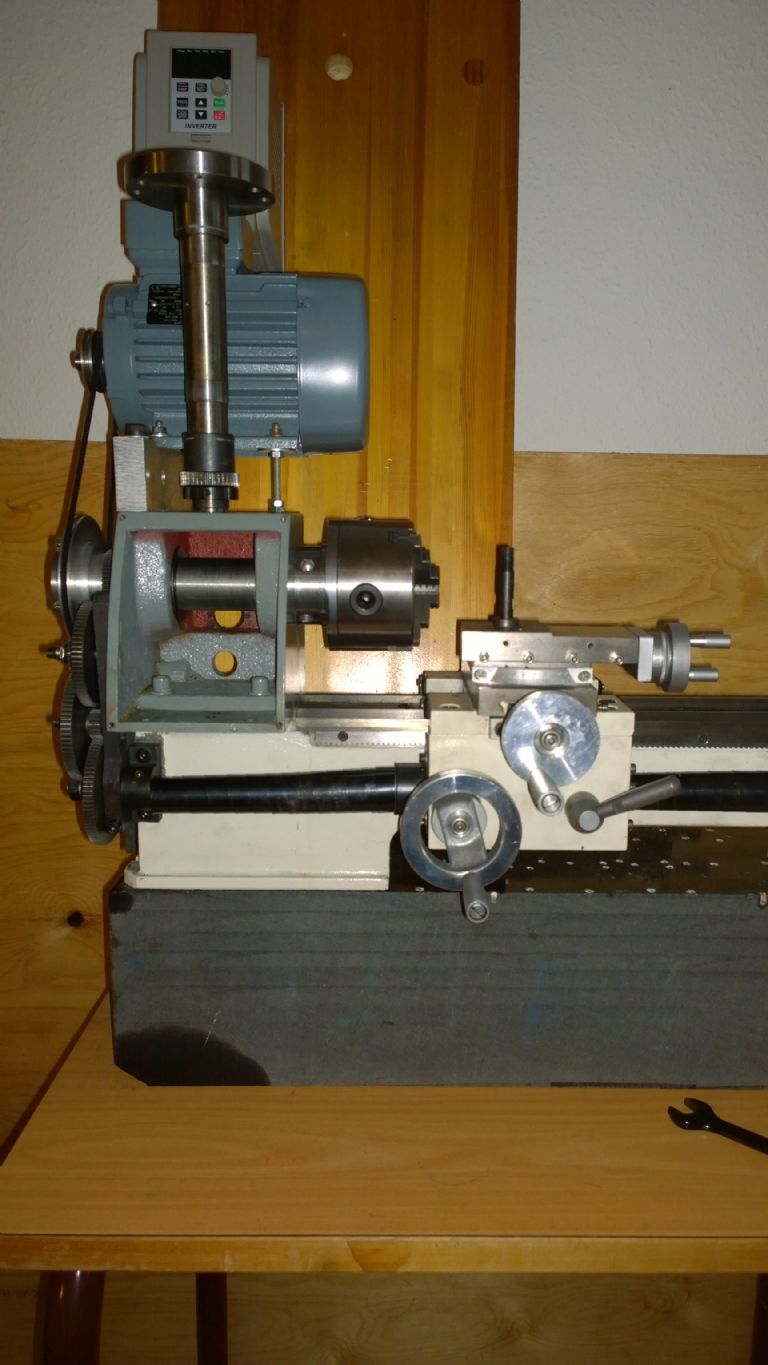

The frame 71 four pole motor turns a 50mm Gates5M belt pulley and spinde pulley is 100mm.

A frame 63 two pole with a 25 mm pulley can then do the same job but wil run two times faster and make more noise.

Will try and compare.

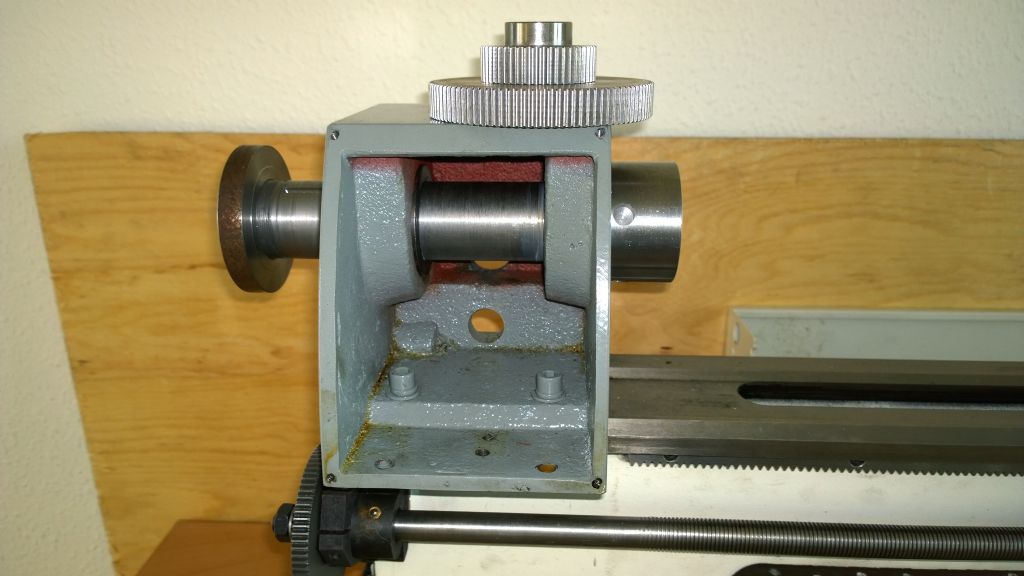

The spindle I am trying to make has 30mm bore full length and is an overkill.

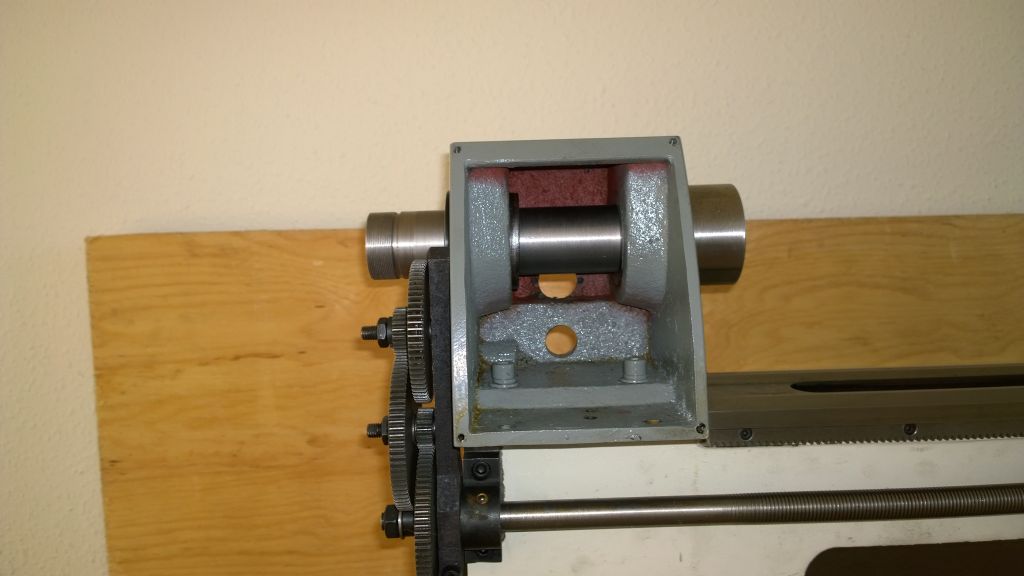

It needs two new bearings, and all the grease seals need modification.The real trouble is the bigger (50 teeth)spindle gear wheel.

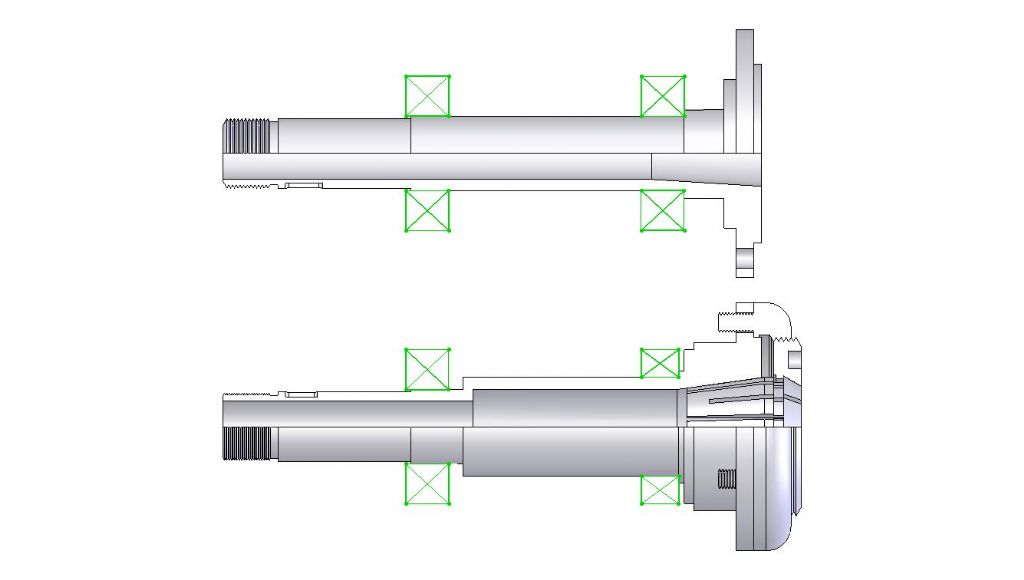

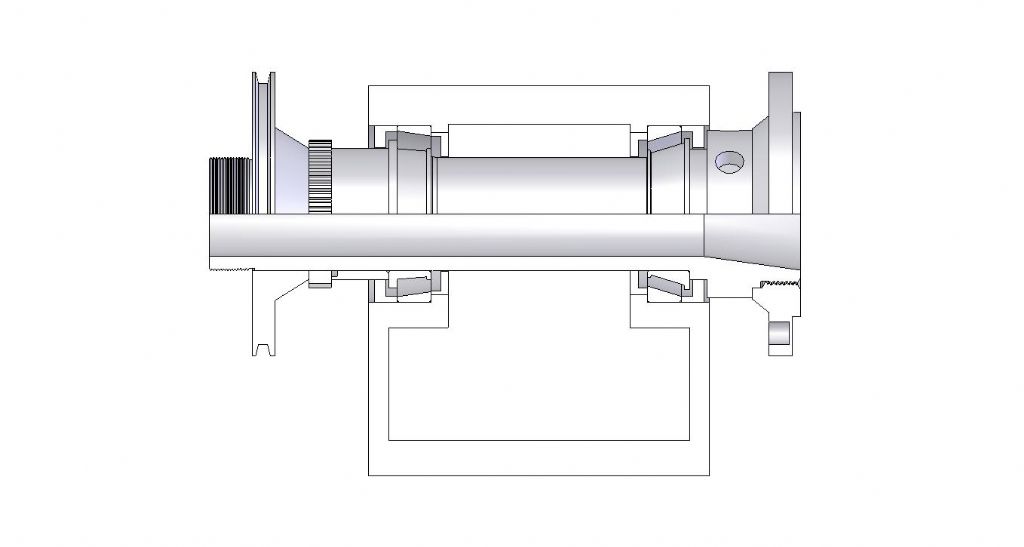

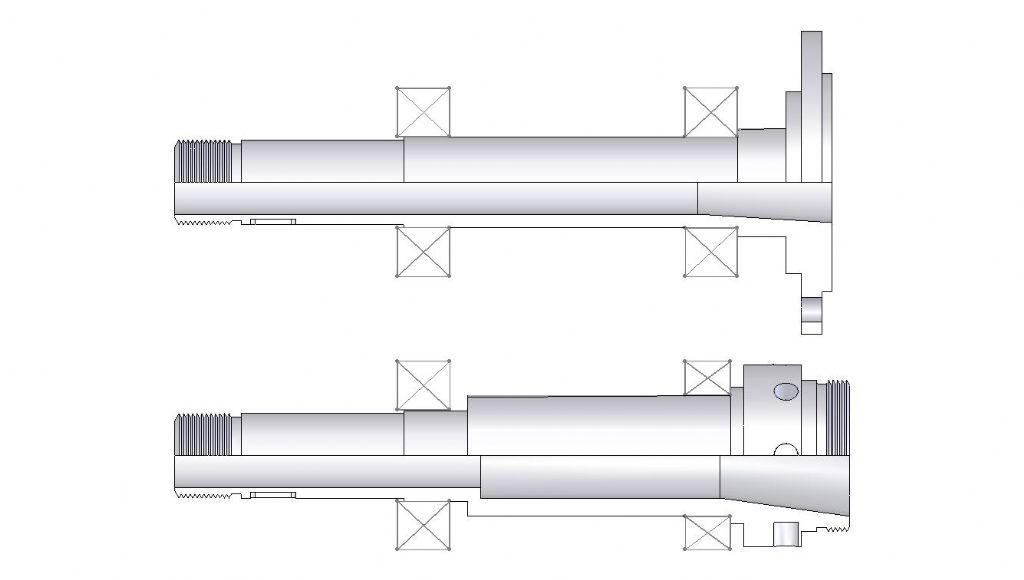

If the spindle looks like the lower of these it will only need to have front bearing changed.

Drive system with electronics and the geartrain to leadscrew can remain as is.

Powered speed range needed for me is 120 to 1200 rpm that can be done with existing DC motor in one step.

I think thats the way to go.

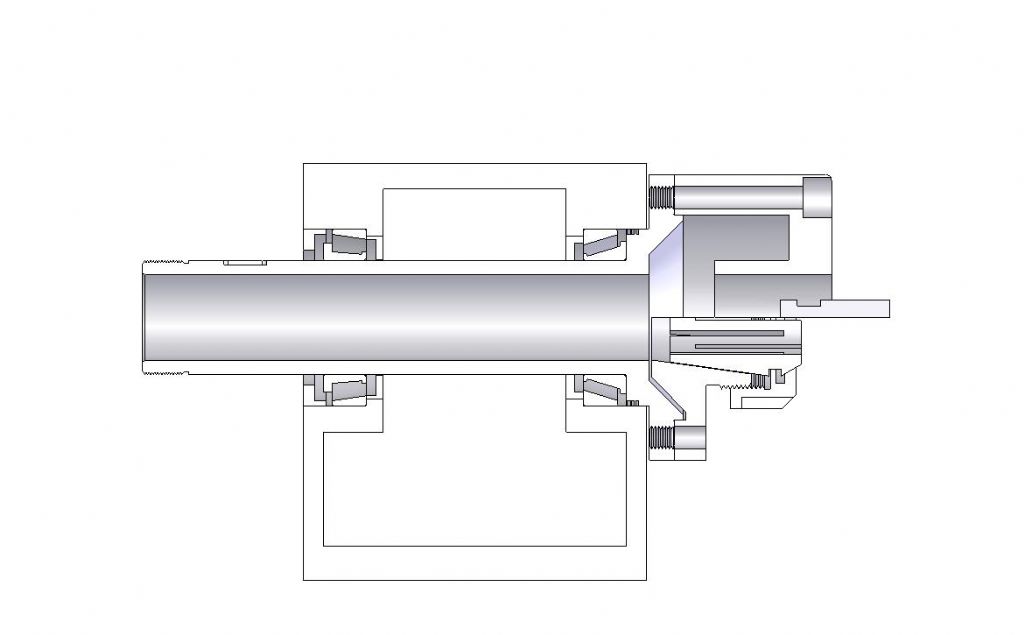

I bougth a MC3 ER40 collet chuck from Arceuro and was not shocked by price.

The factory that made the shown collet chuck/nut can easily make the new spindle for same kind of money.

Material and machining time are identical I think.

It can be a good buissness as there must be many thousands of these mini lathes around.

Edited By Niels Abildgaard on 15/07/2019 12:01:19

Edited By Niels Abildgaard on 15/07/2019 12:04:04

Niels Abildgaard.

![wp_20190418_003[1].jpg wp_20190418_003[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829239.jpg)

![wp_20190418_005[1].jpg wp_20190418_005[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829241.jpg)

![wp_20190409_003[1].jpg wp_20190409_003[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829238.jpg)

![wp_20190418_004[1].jpg wp_20190418_004[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829240.jpg)

![wp_20190712_002[1].jpg wp_20190712_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/834563.jpg)

![wp_20190722_005[1].jpg wp_20190722_005[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835182.jpg)

![wp_20190722_006[1].jpg wp_20190722_006[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835183.jpg)

![wp_20190722_009[1].jpg wp_20190722_009[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835187.jpg)

![wp_20190722_008[1].jpg wp_20190722_008[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835186.jpg)

![wp_20190722_010[1].jpg wp_20190722_010[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835188.jpg)

![Cast iron faceplate death of a Dream.wp_20190731_006[1].jpg Cast iron faceplate death of a Dream.wp_20190731_006[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835799.jpg)

![wp_20190815_001[1].jpg wp_20190815_001[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/837111.jpg)

![wp_20190817_002[1].jpg wp_20190817_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/837106.jpg)