Posted by Bevel on 08/07/2021 08:56:24:

Back again

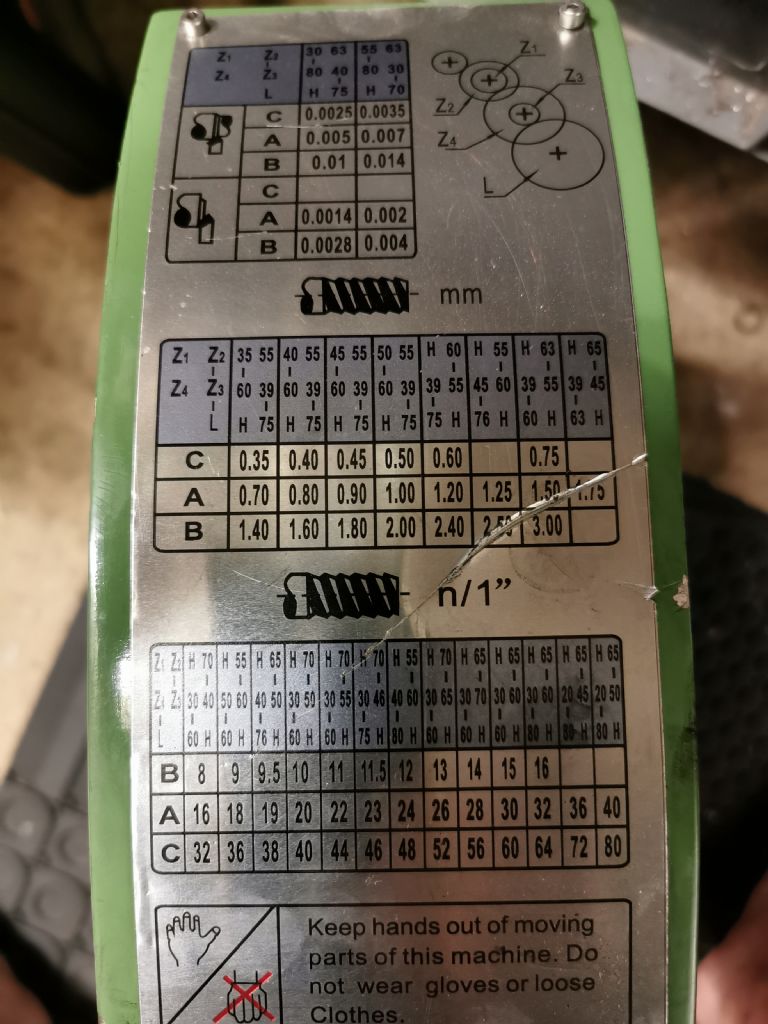

This is the illustration I have on my lathe, in charts quoted by your kind selves there are only 4 gears quoted when mine contains 5?

Confusing isn't it!

It's to do with how Bevel's particular Imperial lathe is set up to cut metric threads. In imperial mode the lower TPI table shows the expected 4 gears, plus two 'H' spacers. And the same is true of the metric threads on the right of Bevel's table. However, to get some metric pitches, his particular lathe adds a 5th gear.

It's a matter of mechanical convenience. Lathe designers have many gear combinations that could be used to generate a particular ratio, and they choose them to comfortably fit in the space available, whilst keeping cost down by minimising the number of gears needed to cover the lathe's design range. Usually, combinations involving very big or very small gears are avoided to reduce wear and tear.

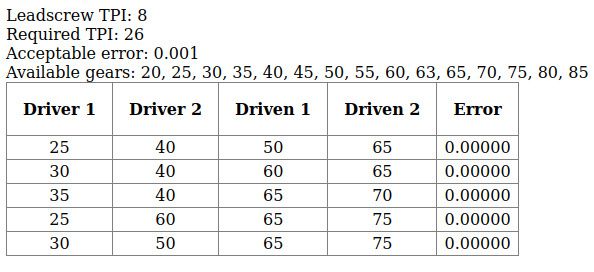

My metric WM280 always uses 4 gears to get metric and imperial, and does so without 63 or 127 toothed gears. The designer achieves this magic by suggesting gear combinations that are close approximations rather than spot on. The imperfections don't matter unless very long threads are cut (longer than the lathe can manage!), or are worse than the lead-screw error. (Which is bad enough for precision screws to be ground rather than turned. Lathe cut threads are 'good enough' rather than highly accurate. )

Calculating the gear combination needed to produce a particular thread is challenging. (Well, I think so.) The easiest way to do it is to write (or find) a computer program that generates all the possible ratios that can be produced from the available gears and ignore all the unwanted answers. Or sort the list by TPI/pitch and use it to look up the gears needed. The table on a lathe is a much shortened version of the full list. Although the maths is simple (see the various programs mentioned recently), the sums have to be repeated thousands of times. It's too much work for a human unless started by finding a near combination and moving in by trial and error. The second way of doing it, which is more practical for paper and pencil methods provided the maths is understood, involves Continued Fractions. Still tedious, and best done with a computer.

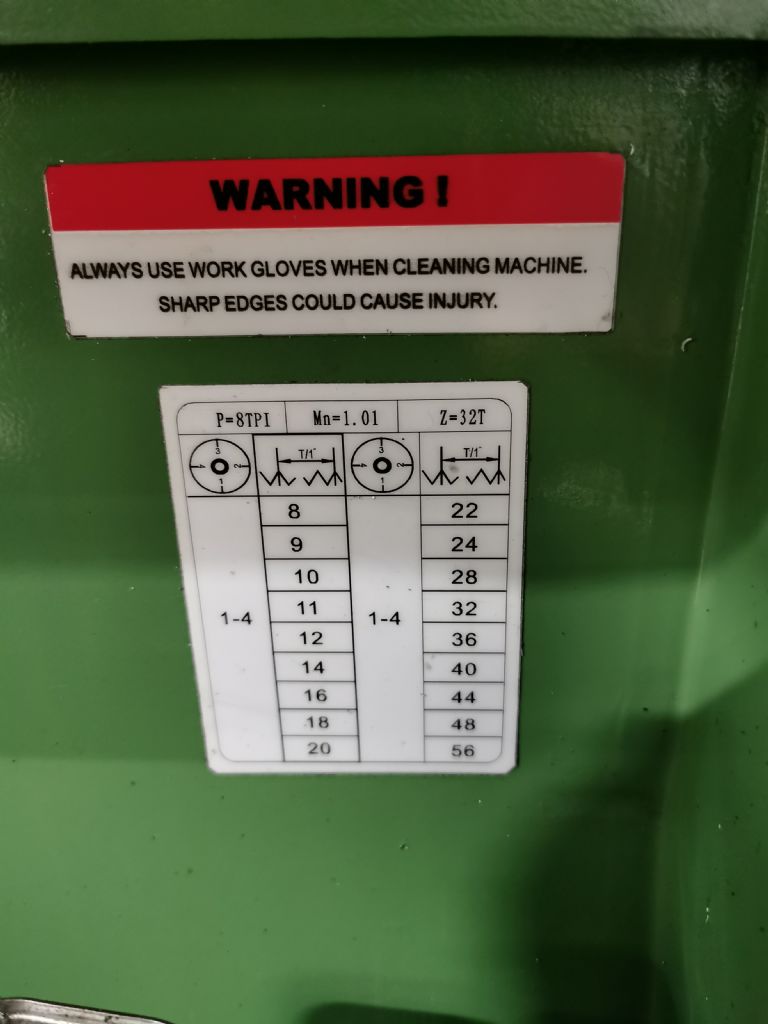

Note that although all lathes are similar, the actual implementation varies. Without checking carefully, I couldn't be sure a program written for an Imperial Super 7 was right for my Chinese metric lathe. For the same reason, the tables printed in books, on the web, or on various headstocks are as likely to confuse as clarify. Necessary to swot up I fear to grip the sums. lathes.co.uk is worth a look and various books have already been mentioned.

Dave

Evan Lewis.