Posted by Stub Mandrel on 28/04/2013 18:03:22:

Hi Stew,

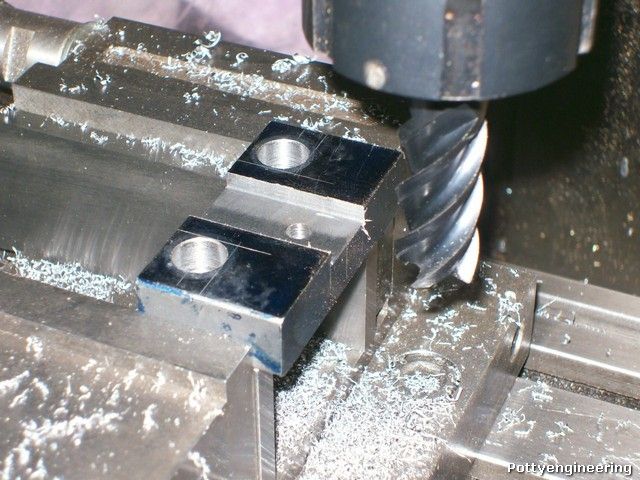

Just a thought, but when I was starting my problems were mostly a lack of small thing: no reamers, very few taps, no mill/vertcal slide, only 1/64" stepped drills and a few metric standard sizes.

Are these the sort of limitations you are allowing for? I assume the small cap-head screws are oneresult of this approach? Might be worth mentioning that 50 M3 countersunk screws from Screwfix go a very long way, and are quite close to 5BA. Ideal for any hidden fixins, or those which can be filled later.

Neil

Hi Neil:- thanks for your input

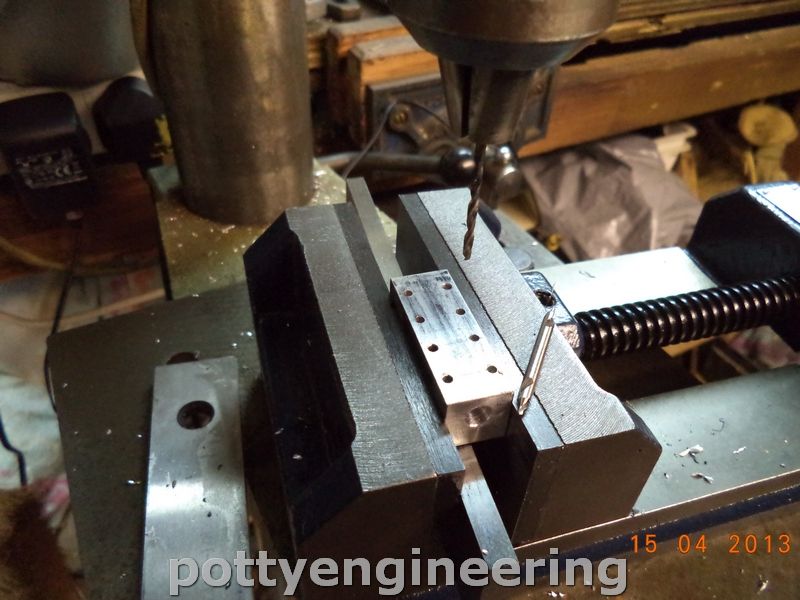

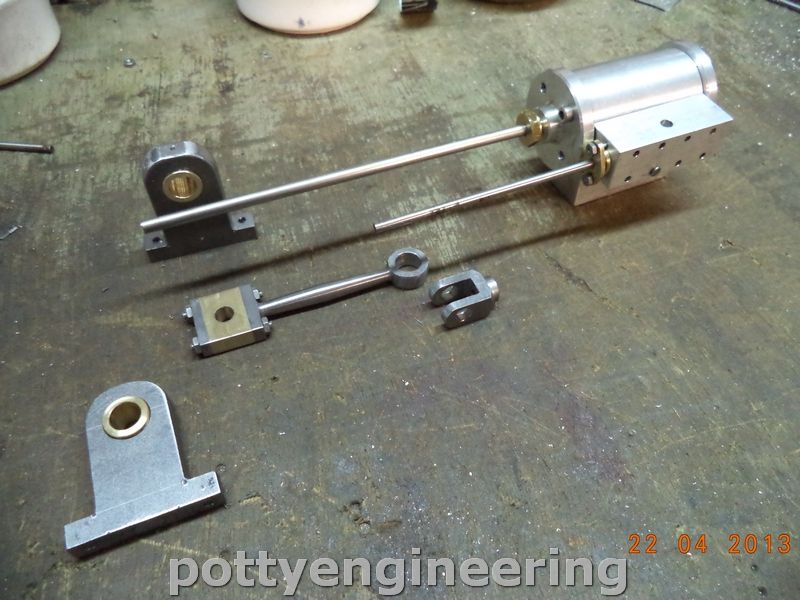

Yes thats the sort of things I'm trying to deal with, I've used metric threads throughout, these being the industrial standard taps and dies and screws are relativly cheap as you have pointed out. I've also kept away from copper based alloys for the main bits using ally and mild steel, I have resorted to brass and stainless for some of the smaller parts as I have plenty of this in my stash but mild steel would be just as sutable.

When I write it up I'm going to include a bill of material stating size and quantity of material required along with thread sizes and with alternative sizes Imperial and unified

And a list of dills required maybe or I may just say set of number drills.

I drew it up in metric but amazingly I found suppliers to the model engineering comunity don't stock metric size material so I had to resort to imperial equavalent.

The fly wheel is causing me some problems I have a 4" Stuart flywheel, but I want to fabricate a wheel out of 4" thick wall steel tube and 1/4" plate.

It would be nice if one of the supliers could supply a kit of material and fixing: in a similar way they do for cast kits. Hint Hint.

Stew

John Harding.

)

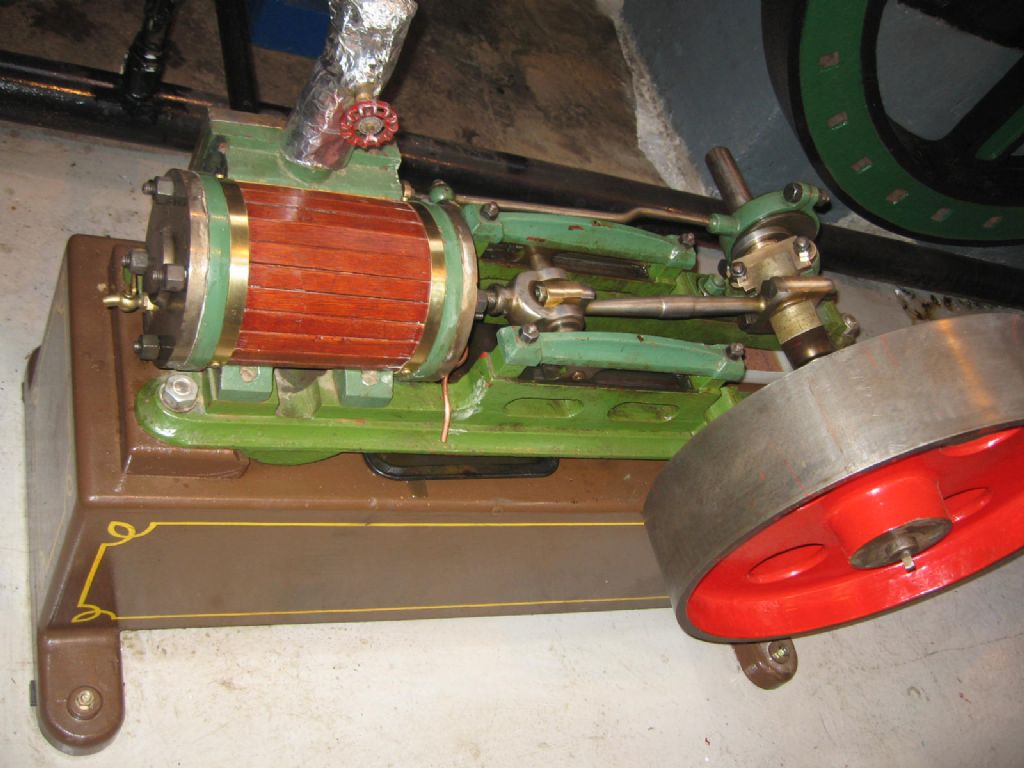

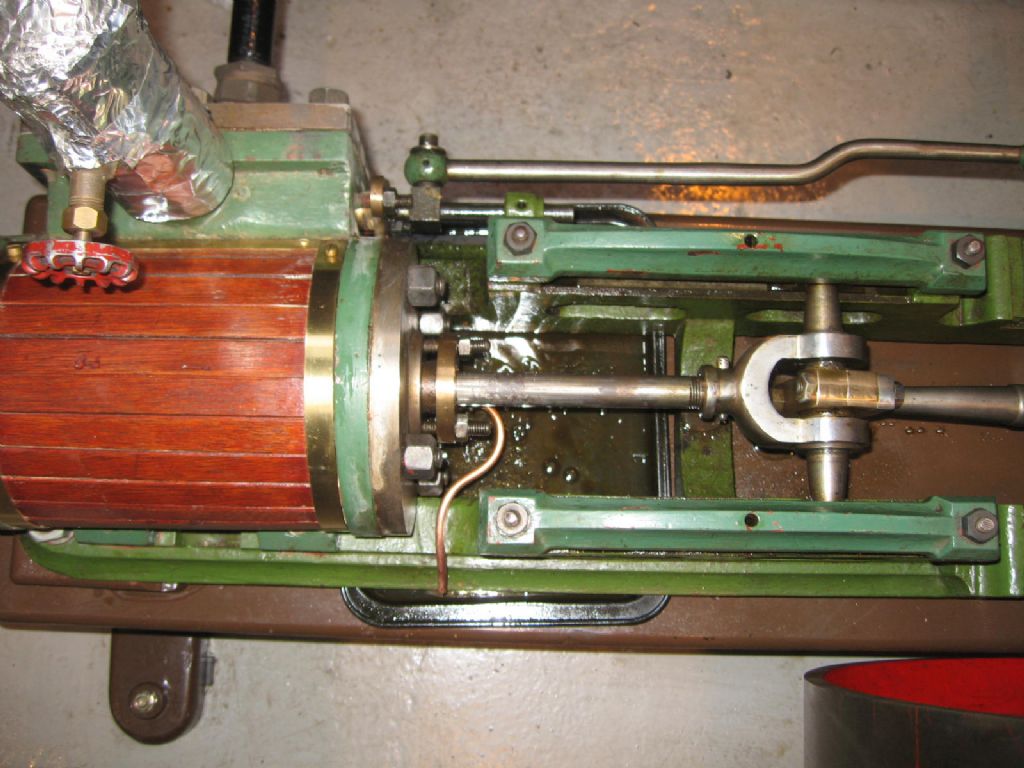

)

Its some water based wood stain and some felt tip pens, the felt tip pens we're useless all dried up but the wood stain was ok, to mark the cement line i just mixed some of the wood stain with some white emulsion and put it on with a thin brush. Then to seal it I watered down some PVA and brushed it over. I don't think it looks too bad.

Its some water based wood stain and some felt tip pens, the felt tip pens we're useless all dried up but the wood stain was ok, to mark the cement line i just mixed some of the wood stain with some white emulsion and put it on with a thin brush. Then to seal it I watered down some PVA and brushed it over. I don't think it looks too bad.