Thanks for that I'll see how it compares. For anyone interested I have put the code for that group of 4 shapes on dropbox. Depths did vary from 1-3mm but you got the size about right.

I was not going to touch the KX3 today but a comment was made on another forum that CNC was like 3D printing with both taking a "hours and hours" to print or machine something. I had mentioned before that the engine I'm just completing had some parts that would have suited CNC machining, these two legs being a good example with the Rotary table work taking me about 5 hours to complete.

I already had them modelled in Alibre so it was just a case of exporting a DXF file and opening that in Cut2D, after a bit of a learning curve as there were a few things I had not done before in Cut2D I had the code after about 10mins. It said that I could cut the part in 8mins 23secs so allowing a second op to form the web on the opposite side 10mins each by CNC.

This is a test one in UPVC which took the 8 and a bit mins, the UPVC is thicker than the metal so it has not cut right through.

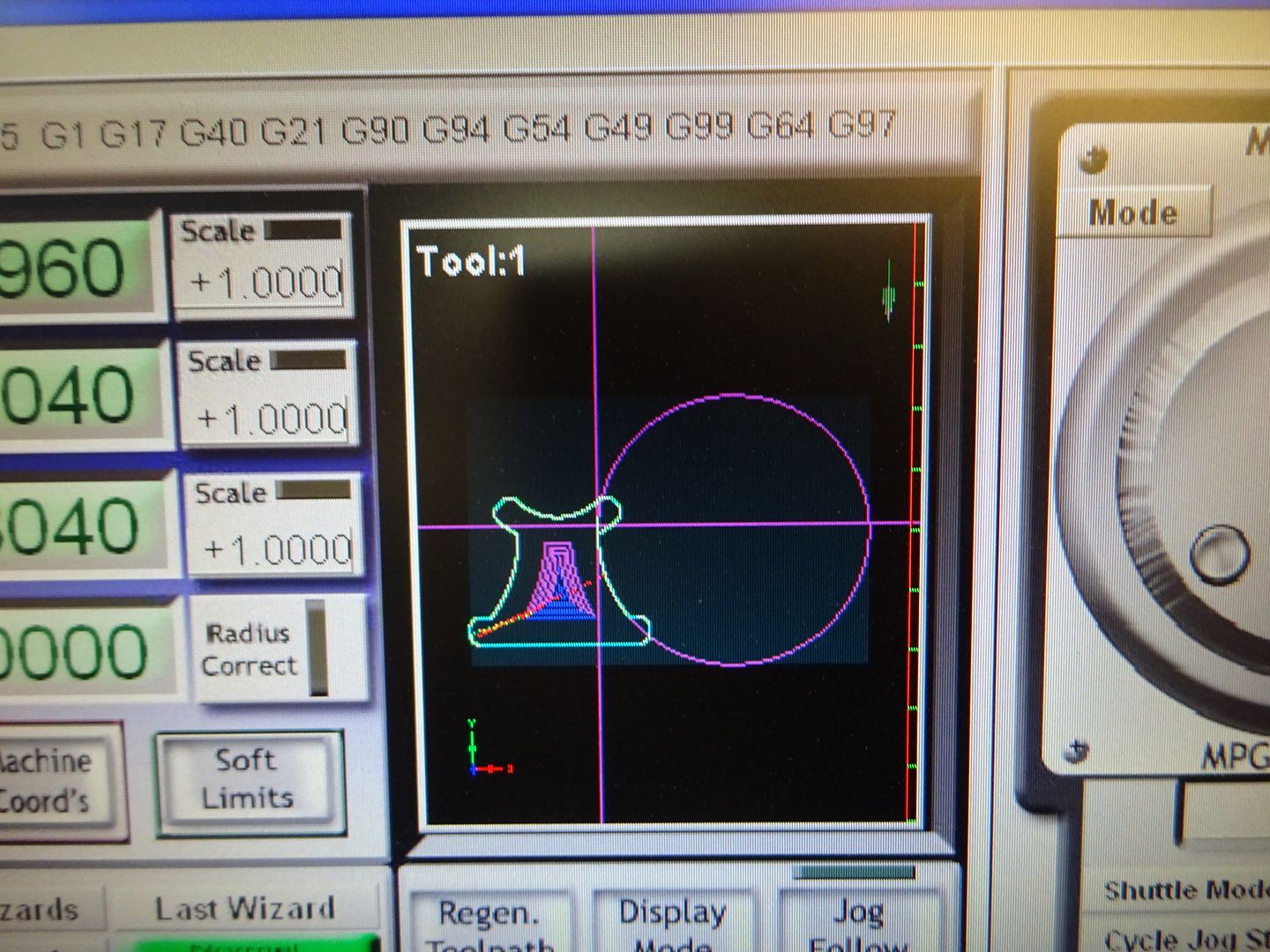

I decided to play safe and before cutting metal reduced the DOC but speeded up the spindle which added about 3mins more to the code. When I loaded the code into Mach3 I noticed an extra path on the screen (pink circle) and should have stopped and sorted it there and then but carried on with my finger over the stop button.

With about 30secs left to run the mill started to move in the wrong direction and luckily I stopped it before too much damage was done, just a nick out of the part.

I redid the code and ran it again and all came out OK in just under 12mins, only downside was I used a bit of scrap with a hole in it.

If I wanted to finish the job then it would just be a case of flipping it over and running the first pocket code again then cutting away the tabs.

I did not video it all but this is 3 clips stitched together showing one pass of each of the 3 ops that form the code.

JasonB.

JasonB.