Hi, my curiosity about the tool Steviegtr bought, lead me to buying one myself and I have to say that his frustrations with this product are valid. Upon inspecting it, it does have a lot of side-play in the arms relative to the holder, this is somewhat due to the use of setscrews holding them in place, but also as there is a 0.27mm clearance between the arm clevis's and the holder, this can be reduced but not eliminated, by using bolts with a plain shank the length of the arm clevis.

I don't know about Steve's one, but mine didn't come with washers between the spring and the arms, this leads to the spring dropping into the small chamfer in the bolt holes and locking the whole thing in certain situations.

Adding a thin washer at both ends of the spring, prevents this locking up happening.

The next thing I noticed, is the bottom end of the bolt has a square edge to it, which also locks the tool when adjusting it down to it's smallest sizes, but also reduces the floating action somewhat, between fully open down to the smallest size.

My small scissor type bolt has a radius edge to it, which seems to stop this type of locking, happening.

Lastly, I don't think the shape of the dimple for the radiused top washer is quite the right shape or quite a large enough diameter, which allows the tool to kind of lock when using it with the arms on the two inner holes for using on smaller size diameters.

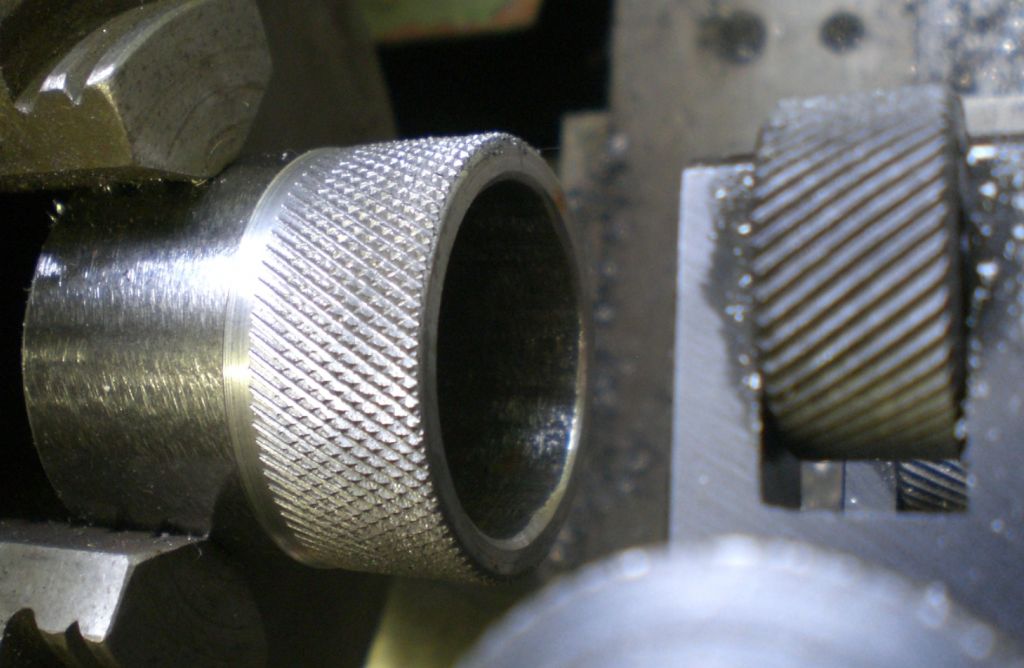

I did three samples with the tool, the first one from left to right in the photo below, was with the setscrews in place and was done on a piece of trued up black steel pipe, which is about 33mm diameter on the outside, the second one was done on a piece of 25mm EN8, but the set screws were replaced by plain shank bolts and the third one was done on a piece of 25mm unleaded mild steel, all of these were with the washers in place at each end of the spring. I think the worst result is on the mild steel one, but it can be clearly seen that the side-play in the arms move the knurl's out of line with each other in the opposite directions. I think it is clear that this tool does need some reworking done on it to make it a satisfactory tool to use and it may mean making a new holder to reduce the clearance in the arm clevis's and bespoke clevis pins to reduce the slop in the holes that hold the arms in place. Whether one thinks it is poorly made or not is up to the individual as it does work, but certainly not to a high spec.

Regards Nick.

Edited By Nicholas Farr on 15/08/2021 09:34:16

Steviegtr.

Steviegtr.