Ian

No, I don’t hear a click from the capacitor now but when the old switch was connected to the motor yes there was a click after switch off.

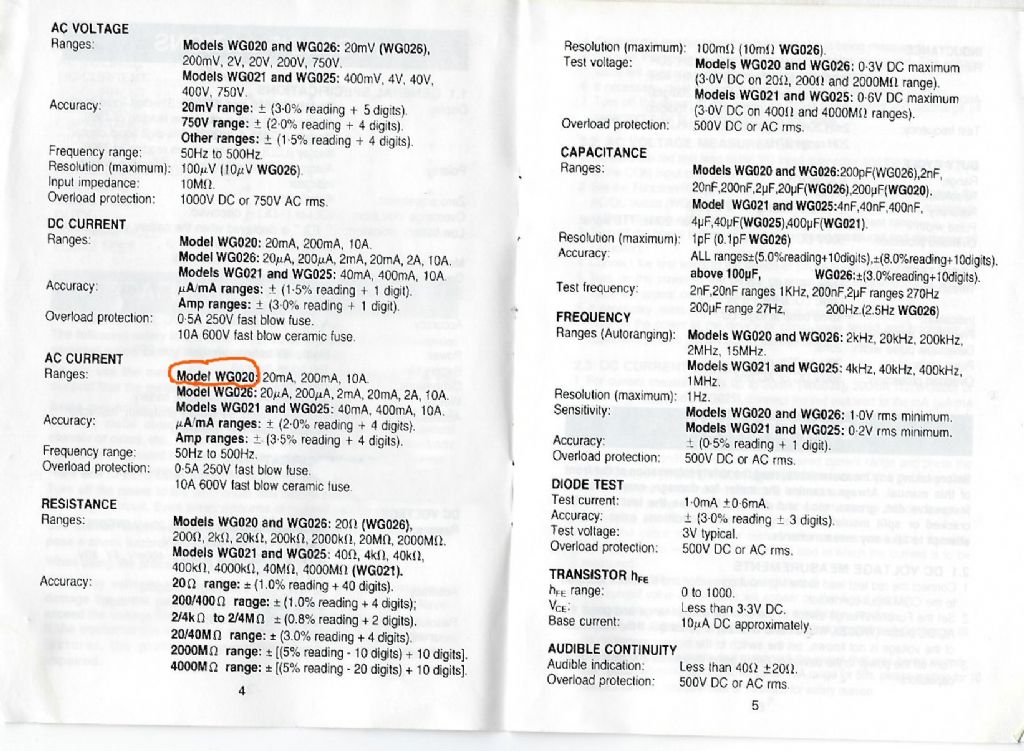

I do have a multimeter but have to admit I’ve only used it for doing bits of continuity checks on the car.

I’ve included a picture of it to give you an idea of what it’s like.

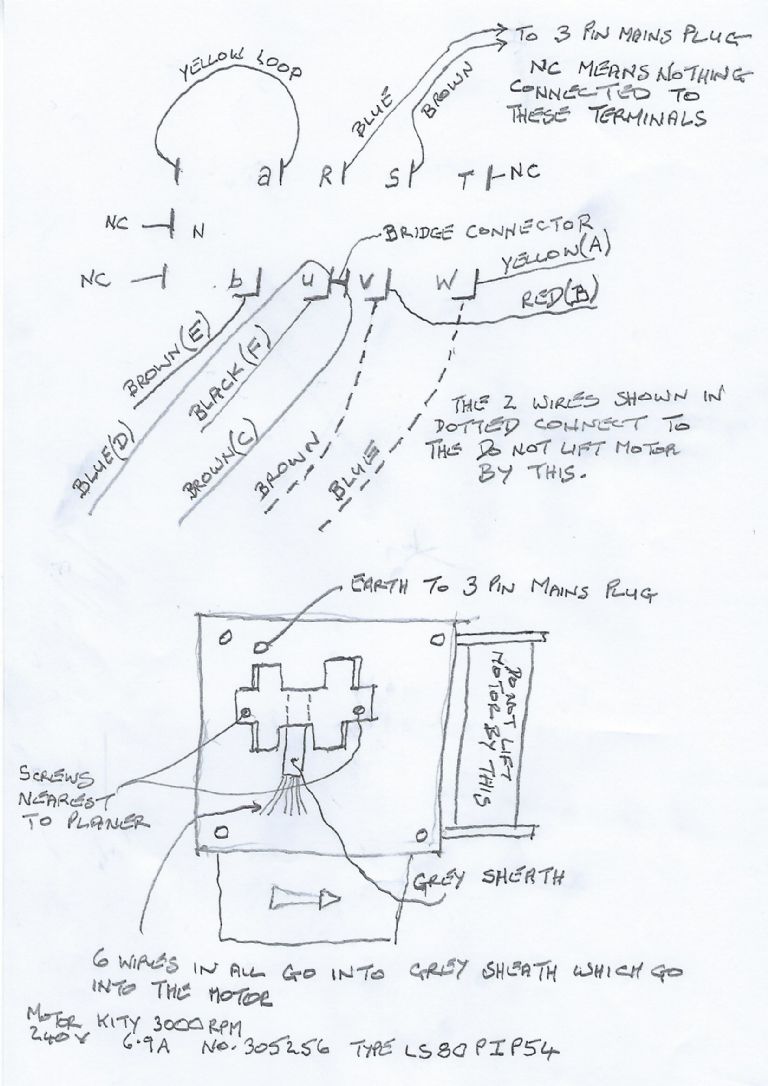

If I do have to do tests on the wires is there any better way of joining them together because at the moment, I haven’t cut the spade connectors off and they are only held together with electrical tape so not exactly the tightest of connections.

I left the spades on just in case I end up having refit the old switch.

Switches, I understand what you say about stop switches, I haven’t bought anything yet as I wanted to try and get the wiring sorted out first and then get advice of you guys on what would be best to go for as I don't want to end up buying the wrong things.

I have had a reply from Axminster Tools as follows:

Used primarily for motor switching.

Three different ratings to suit single phase motor powers from 750W – 3.75kW

Units for 750W, 2.25kW or 3.75kW motors.

Adjustable overload protection:

340192 – 6A to 8A

340193 – 14A to 17A

340194 – 17A to 21A

Can be used with additional foot switches, interlocking micro switches or thermal overloads.

175mm (6⁷⁄₈ʺ high x 100mm (4ʺ

high x 100mm (4ʺ wide x 130mm (51⁄₈ʺ

wide x 130mm (51⁄₈ʺ deep

deep

IP54 rated against dust and moisture ingress.

You can add glands and stops if you want, but if modified it in any way and does not work we cannot arrange a return/refund.

Kind regards

Ian the above is info is about the switch I spoke of in my previous posting.

I have still had to contact Axminster again because on their web site they have conflicting info ie. 2.25kW reads as 1,500W on their drop down price list.

Thanks again

Clive

noel shelley.

high x 100mm (4ʺ

high x 100mm (4ʺ