Things have changed a lot in last couple of years. I don't know about anyone else but i've currently not a lot of free cash to spend on tooling or anything else for that matter.

I moved house 5 yrs ago & a lot of DIY was needed, so the machining had to take a back seat.

Now thouroughly sick of the DIY so Lathe & mill dusted off & enthusiasm re-kindled.

That as it may, a couple of years ago i was feling somewhat more flush & hankering after some machining. A few purchases made from Arc & other sources~ promptly dumped into a box & all but forgotten.

I found the box. Inside amongst other things were a SC4 faceplate & a 5" 3 jaw chuck from Arc.

Finally time to unbox.

Hope the following will be of use to someone.

If you've a mini lathe with a 100mm spindle & bought the face plate to fit, maybe like me you were slightly disappointed, the spindle flange makes for very short slots on the face plate.

The 80mm version looks a bit more useful to my eyes.

Pleased to report the SC4 face plate fits fine, Though there really is very little clearance between plate & bed.

It's a very massive item compared to the standard offering~ perhaps that's not such a bad thing for off centre work & the likely low speeds involved?

Worth your comsideration.

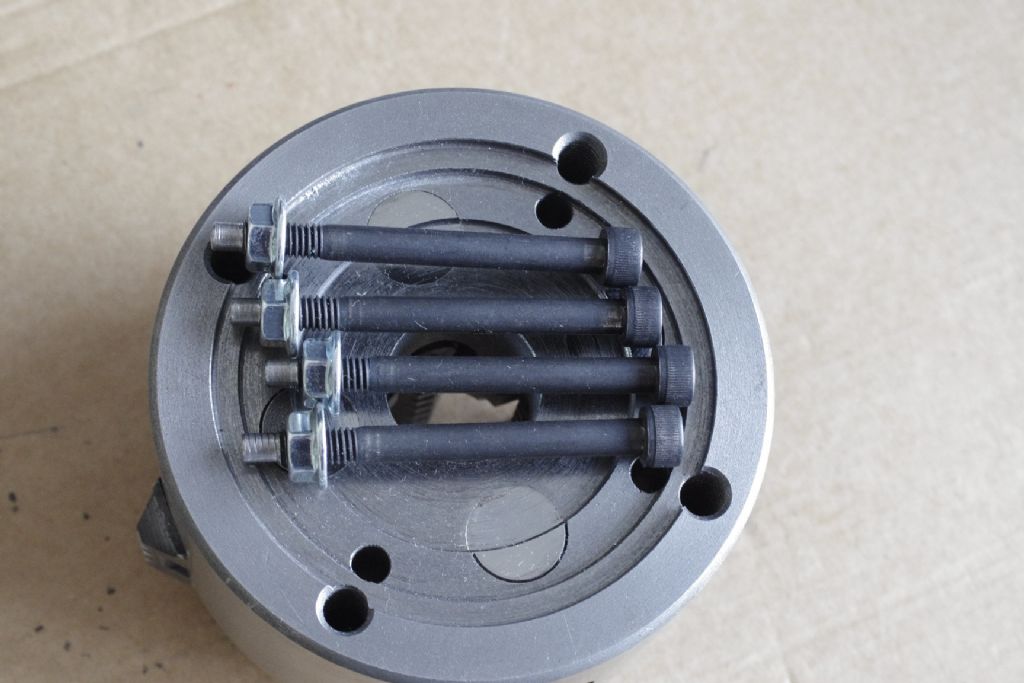

Now to the 5" chuck.

backplate, spindle & chuck all fitted together nicely, thanks Arc.

This thing looks slightly rediculous on the mini lathe.

Spun up, DTI readings taken, test cuts made.

A few things you might want to consider before mounting a 5" chuck on your mini lathe.

Runout was no better or worse than any 4" chinese self centering chuck i've tried bout 3 thou.. Yet to clean & re-lube the internals, so may get a little better,or not.

Nice 30mm bore, After investigating first, it may well be possible to bore out to 1.25". I'd be a happy camper, use 1.25" stock a fair bit.

Spun up to approx 1000rpm max, not sure i'd be happy pushing this up to 2500rpm , maybe i'm over cautious. No spurious noises, in fact the lathe seemed quieter than with a 4" chuck. Go figure??

A couple of vibration points @ certain rpm , but seems that way with my mini lathe whatever is mounted on the headstock..

Good as gold @ the low rpms i'm likely to use this for.

Some points for you to consider:

The chuck & backplate eats into your center to center distance, Probably not a problem….

I doubt many people mount foot long 4" dia work in a mini lathe.

I did once. thankfully the 4" chuck & a custom built center did the trick.

thankfully the 4" chuck & a custom built center did the trick.

Typical swing over the mini lathe crosslide <4 1/2"

You will either need to have 100% concentration or maybe fit a suitable carriage stop otherwise you WILL crash the carriage into the chuck/ chuck jaws….sooner or later.

I don't think a 5" chuck on the mini lathe is a one size fits all, fit & forget solution. I will only be using when necessary.

I don't have the math but 5" chuck & high speed sounds like overloading something to me.

Maybe you know better.

Consider it a useful tool where conditions warrant. Looks like i;ll be able to turn 2" stock using inside jaws now.

Probably the extra mass will give a flywheel effect & a better finish pass~ one can but hope! Early days yet.

samuel heywood.