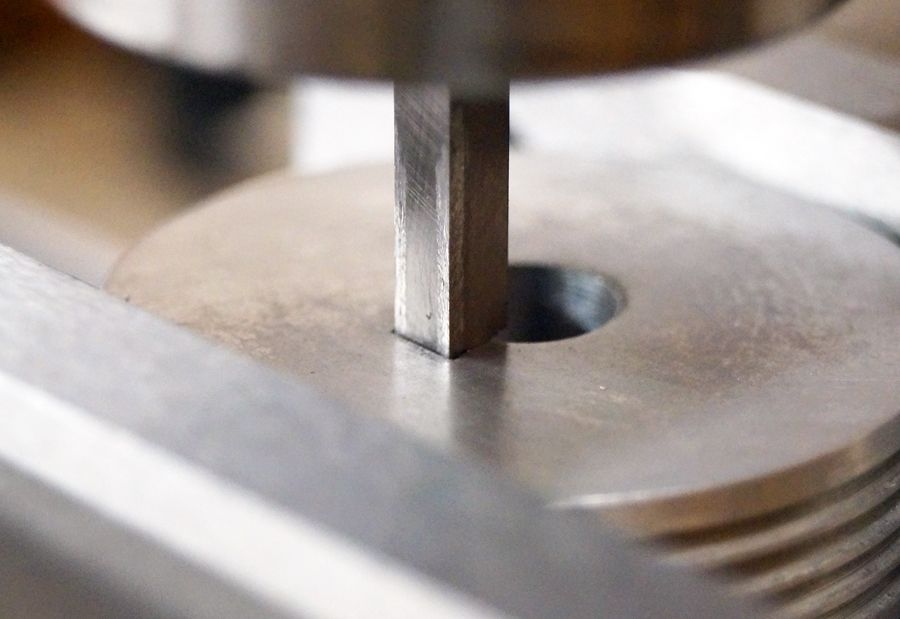

I'm sure we have discussed this before…but anyway, assuming you don't happen to have a slotter or a shaper lying around, make a plug of the same sort of material to just fit the hole. Loctite it in, flush at one end. Make a centre pop mark on the line where the two materials join just where you want the keyway. In the drill press, drill a hole just under the size that the keyway is supposed to be. Knock the plug out, using heat if necessary, and now you have about 75% of your keyway done. With a suitable file, file out the corners to make it square, trying the key frequently until you have a good fit.

You can do them on a shaper, and since I have three shapers I have done this, but if you only have one or two to do it is faster to do them by hand as described above, since otherwise you have to mess around making up the right tooling for the shaper.

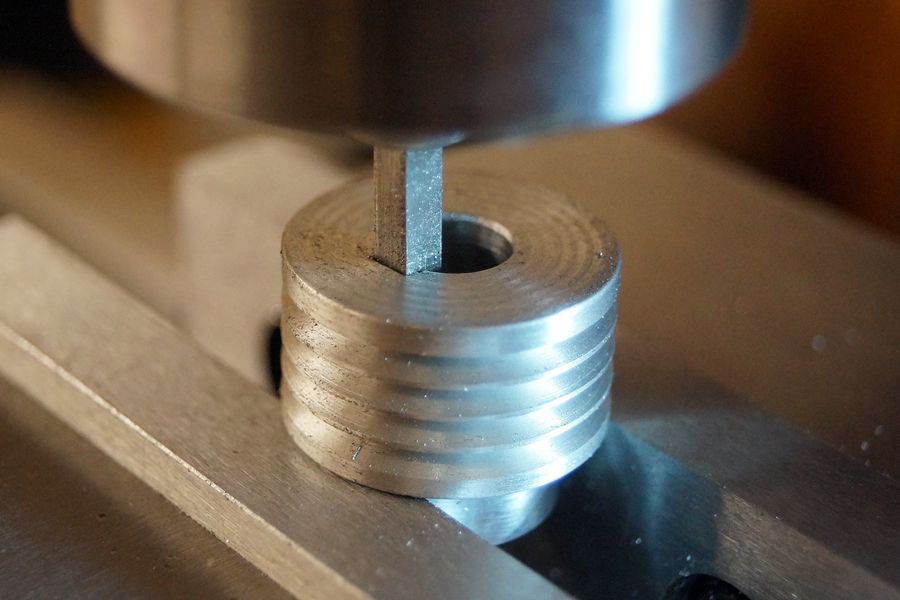

For the shaft, a slot drill as described earlier is good, but otherwise they can be done by hand too. You drill a hole at each end and then chisel out the material between with a small cold chisel. The old millwrights did a lot of them this way, since the shafts were often not readily removable to take to a machine.

John

Ron Laden.