I like to test run my engines before painting as it saves risking any damage to the paintwork if you have to strip things down to do any alterations. If your fits are OK you should be able to test without any gaskets and just one O ring. As you assemble the engine check that it turns over smoothly after each bit is added as this makes it easier to see where things may be binding.

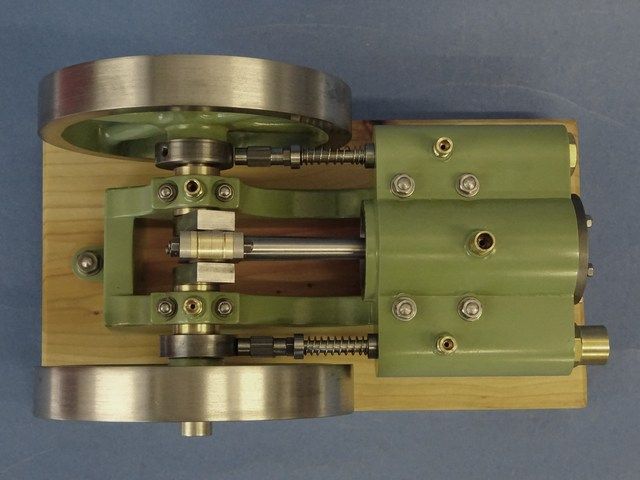

The inlet eccentric should be set so that the inlet is open from TDC until about 5degrees before BDC. The Exhaust should open at BDC and close 5deg Before TDC.

Add a drop of oil to the moving parts and connect up some air and see how it goes.

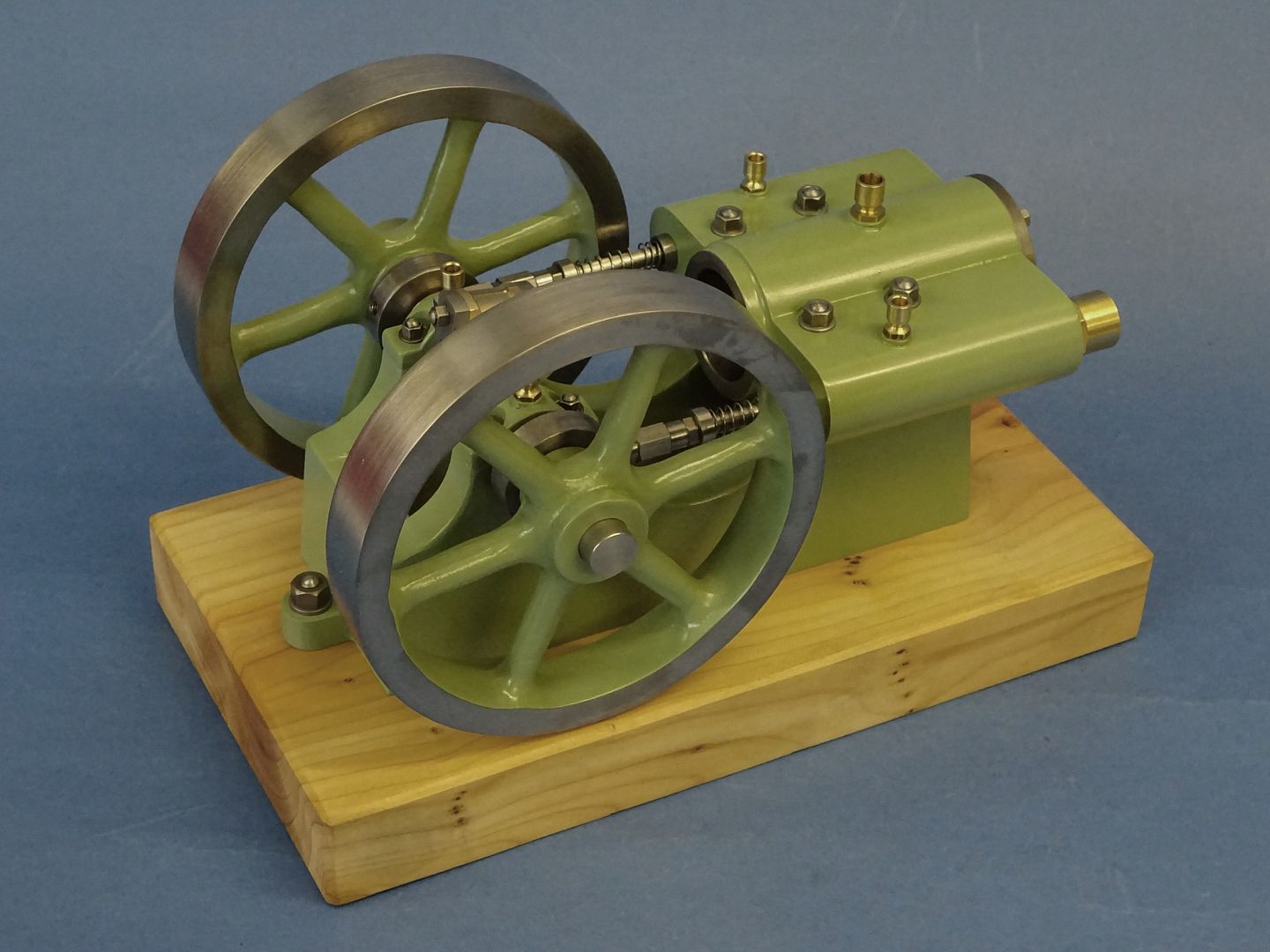

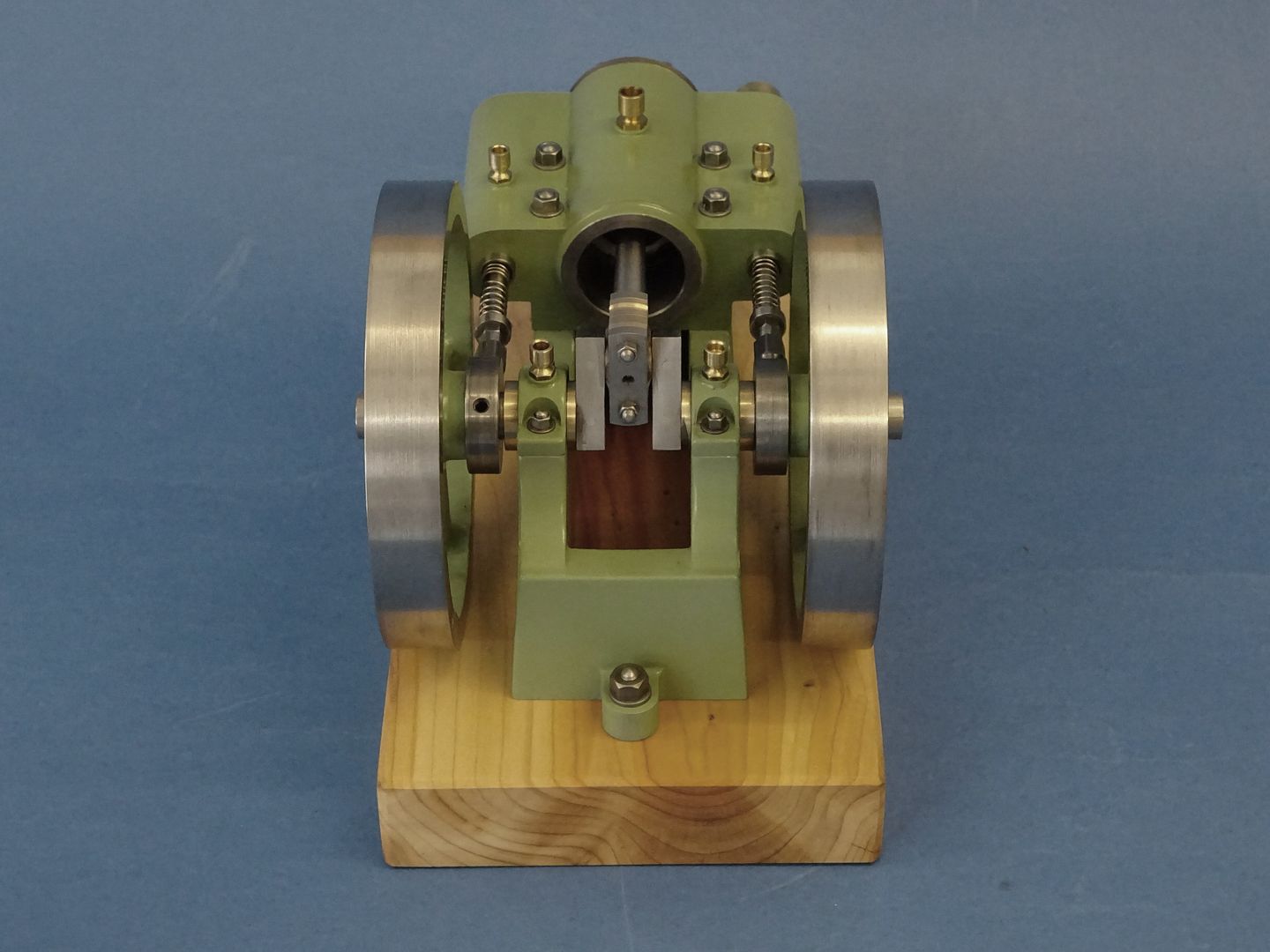

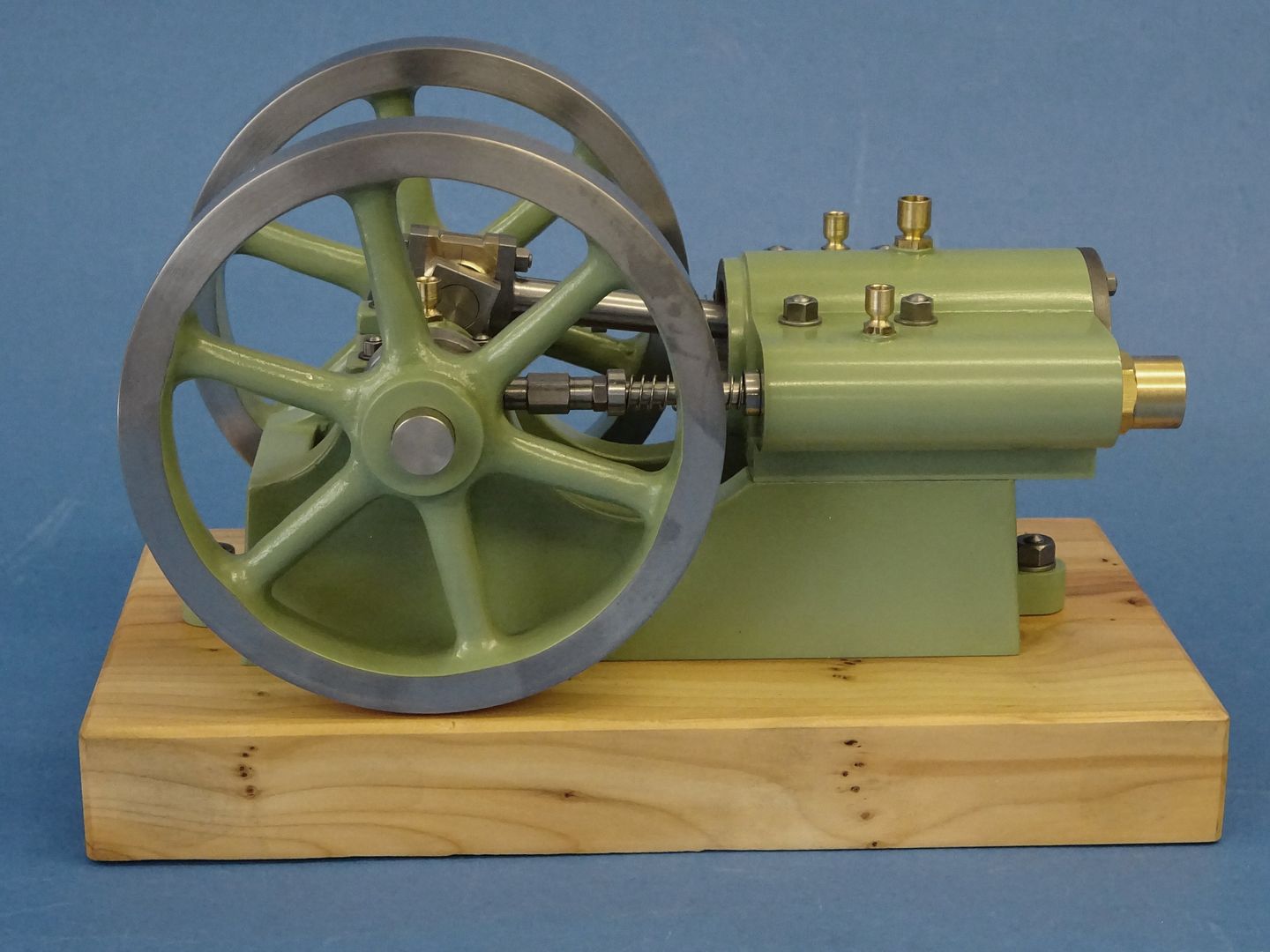

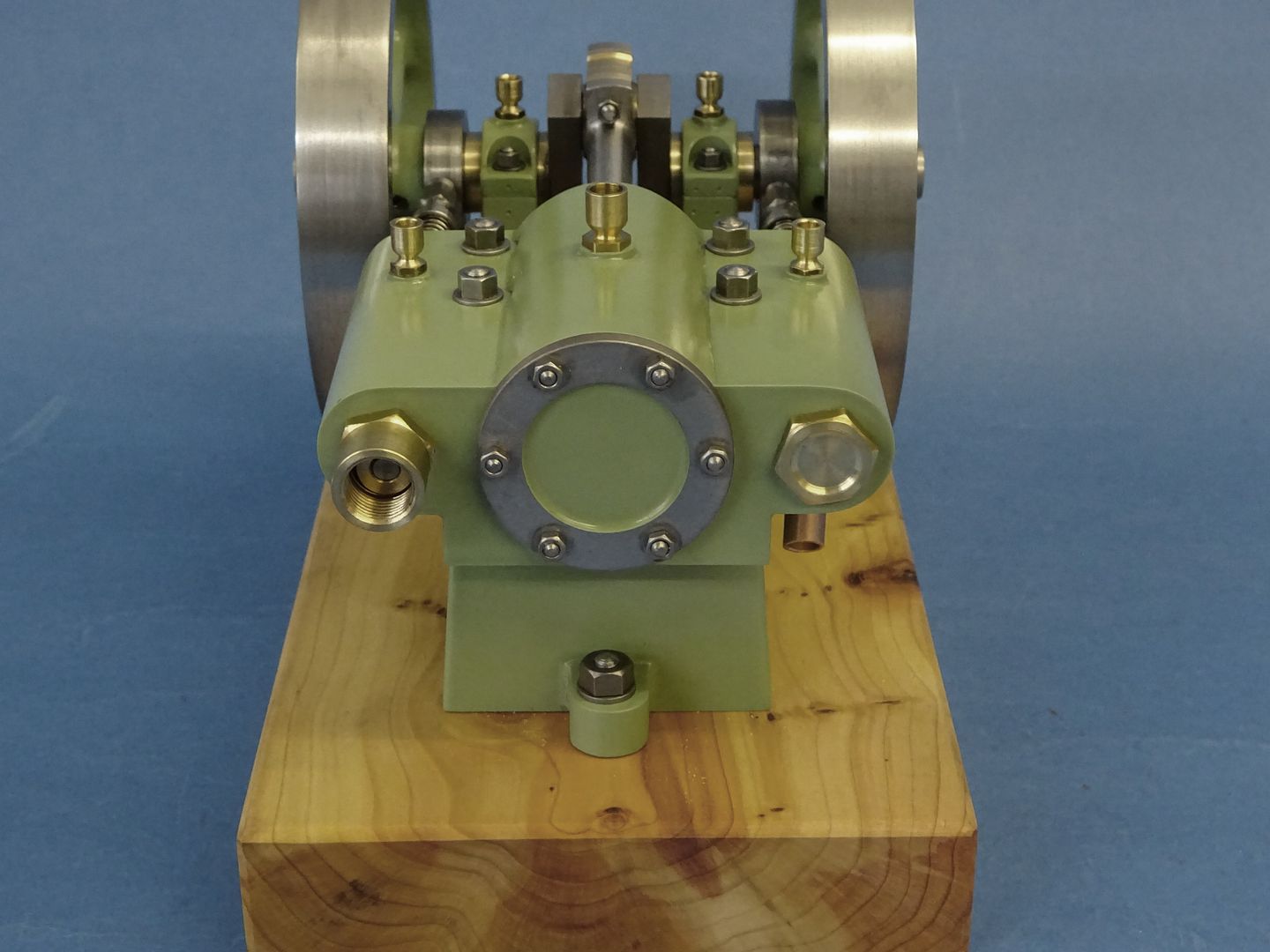

If all goes well then the engine can be stripped for painting. Give the parts a wipe over with thinners, prime and then top coat, I used spray cans on this one and settled on Ford "Moss Green" For the base I went with a simple piece of Yew that I had been seasoning for a few years.

As you build the engine back up check for smooth running as a bit of stray paint can throw things out. If all is well you should be able to flick the flywheels over like this before the conrod is fitted, the valve springs do slow things down but you should get quite a few turns and a nice gentle stop.

The finished engine, not bad for 29day from start to finish working a couple of evenings a week and part of the weekends.

And finally The complete engien running on a couple of psi of air

I hope this has been of interest to someone, there is very little feedback on this forum so its hard to know if I'm just posting for the sake of it or if anyone is finding it useful. I would like to thank the couple of members who have PM'd me with a few comments on the drawings which has allowed me to make the odd alteration so they should be Ok if anyone wants to have a go at making one of these engines.

The End, Jason

JasonB.

JasonB.