My pendulum exhibits an interesting rod 'vibration' mode..

I suspect this is inherent in all pendulums but passes unobserved due to the way the period is measured by most folk.

Since my pendulum is amplitude controlled by measuring the PP swing sinus voltage, the quality of that measurement is key to generating a clean stimulation sinusoid. The PP measurement is done by means of a 2 op-amp Peak detector ( typical 3 diode/op amp peak detector). My PP swing logging shows noise, which I believe stems from the peak detector – the peak detector works by 'topping' up a storage capacitor to the peak value of the sinus, but the opamp that generates this top-up voltage operates open-loop til top-up time, and the top-up interval seems to vary, which means the peak voltage on the storage cap varies, which means my drive voltage to the pendulum coil varies… Not much, 8 to 14mv, which equates to 14 millidegrees swing variation max. I am still unsure how to equate 14 millidegrees variation to a ppm value in pendulum stability…

However..

In pursuing a cleaner PP measurement method, I notice a regular modulation on the logged PP swing sinus – at first I thought this was the Peak detector somehow feeding through – I replaced the peak detector output with an equivalent fixed voltage. The pendulum was now not amplitude controlled, but was driven, with no peak detector artifacts able to affect it. Made no change.

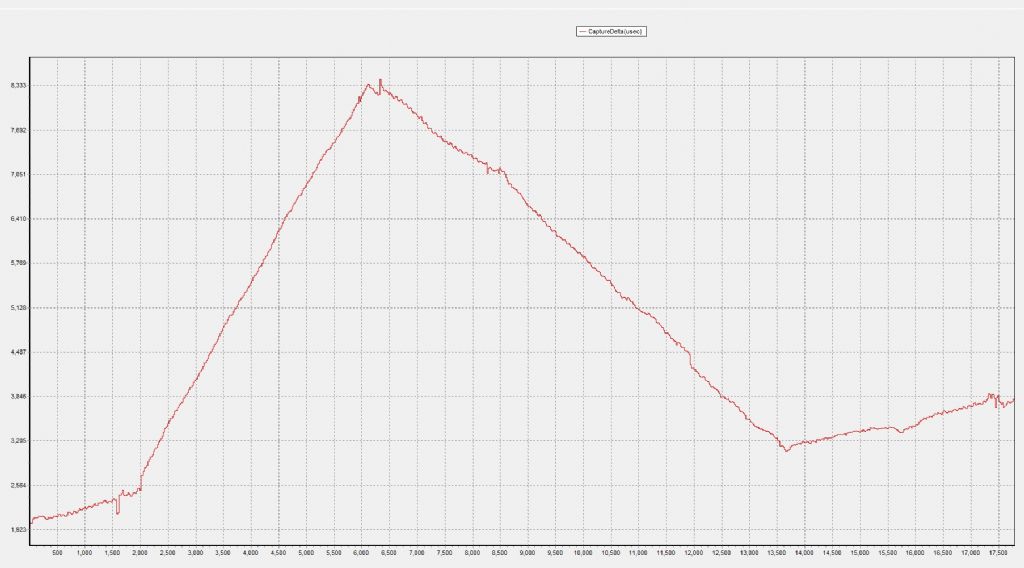

I then disconnected the sinus drive to the pendulum coil, and let is run down to 10% swing. Made no difference to the modulation phenomena – did a Q calc to verify the pendulum is still 'OK' – Q = 12900, so OK.

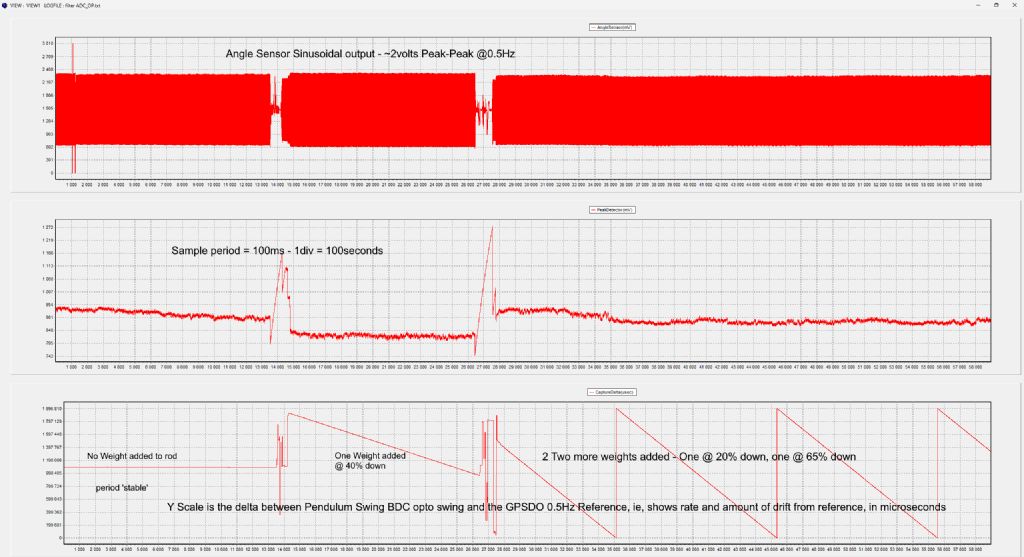

Then I reconnected every thing up, did a run and logged it –

This shows a modulation depth of around 10mv – 10milligrees at a 50 second period.

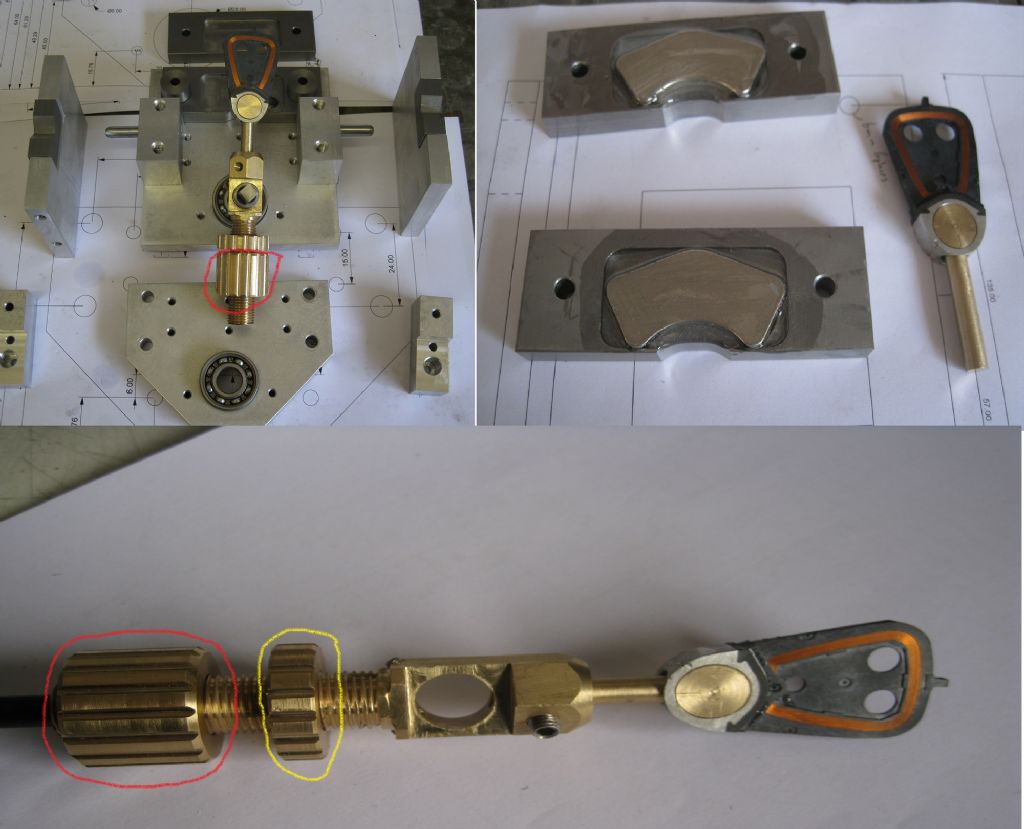

I then moved/fiddled with the knife pivot location point, ie, moved the knife forward about 0.2mm, so it was 'riding' up the inner ball race support surface. This meant the knife was twisted in its circular support pivot, and would add some odd motion to the swing.

I then logged data again – I did observe a new modulation on the Swing sinus, but at a 2sec period, ie, same as the pendulum period – I could also see the bob was swinging in an ellipse, rather than a straight line. However, the 50sec modulation period remained unchanged, so it was not induced by the knife or pivot or its friction, etc.

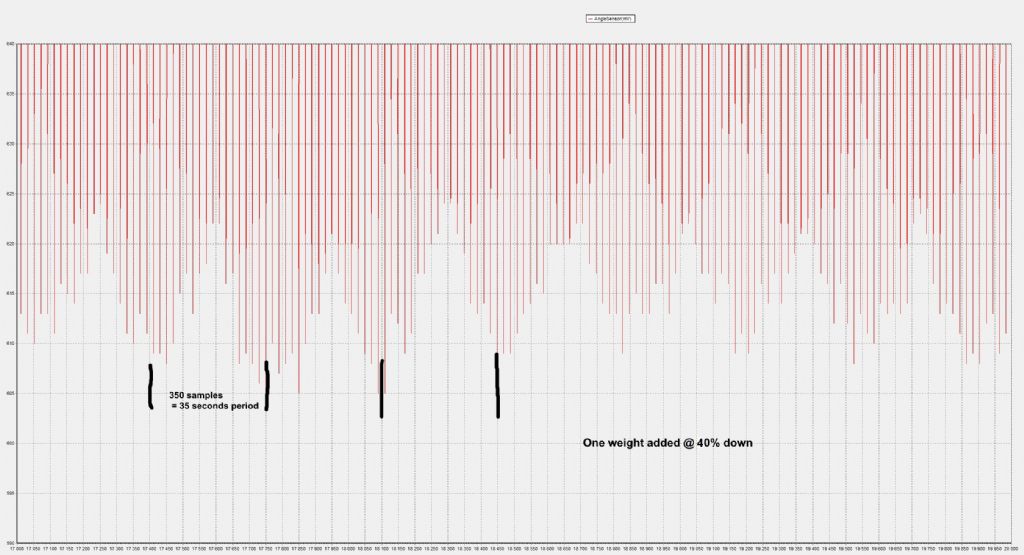

I then added a weight to the pendulum rod – an AA penlight cell fitted with masking tape.. – at 40% down from pivot, and logged data –

This showed the same modulation depth approx, but the period was now 35 seconds.

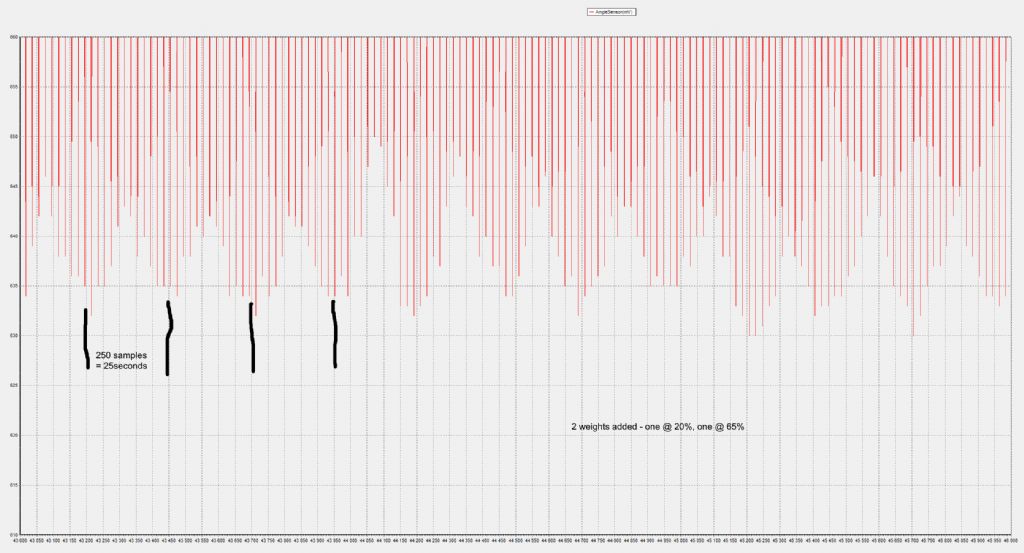

I then added 2 more weights ( AA cells) one at 20% down, one at 65% down.

The period changed to 25 seconds.

So – the rod somehow has a very long period vibration mode, or a High frequency vibration mode, which influences the pendulum period in a very cyclic manner. I suspect everyone using light weight 'stiff' rods has similar modes, but do not see them due the to measurement methods.

This shows the three logs, no weight, one weight 3 weights.

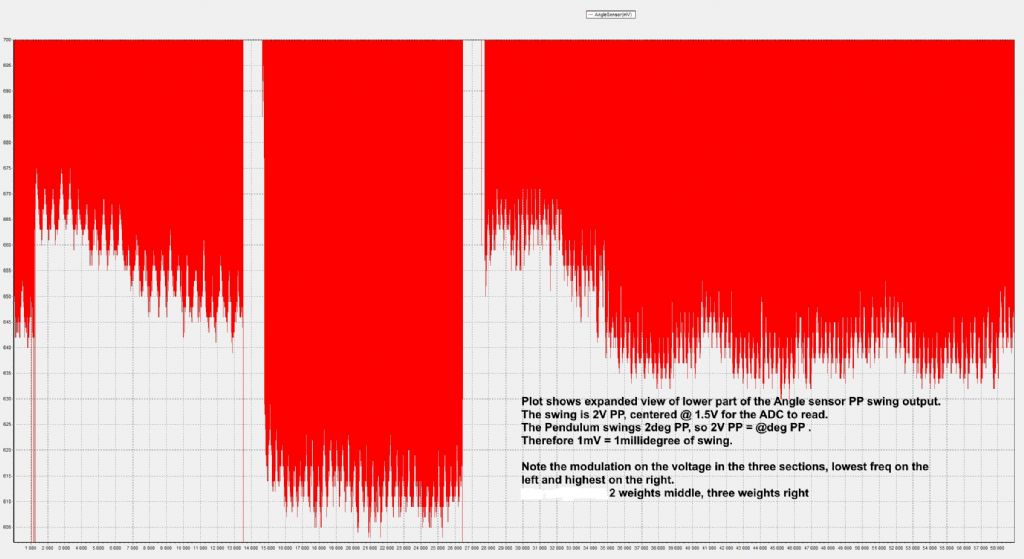

Expanded view of the bottom peaks of the sinus swing, shows the 3 varying modulation frequencies

No weight

1 Weight

The carbon fibre tube is a no-no – maybe a solid carbon fibre rod will improve matters, but that prevents fitting wires internally to my sensors in the rod and bob. And solid carbon rods temp coef is a lot poorer than a tube, so I would be better off using Invar…

And I am pretty sure the house is not vibrating at those frequencies…

The issue is evaluating how much of an effect this modulation has on the pendulum period – it is cyclic, 10 millidegrees, which can be validated in change of period, but the cyclic nature undoes what it causes on a regular basis. Not sure if I am chasing ghosts here.

Edited By Joseph Noci 1 on 03/10/2023 08:49:25

SillyOldDuffer.