The Pendulum so far –

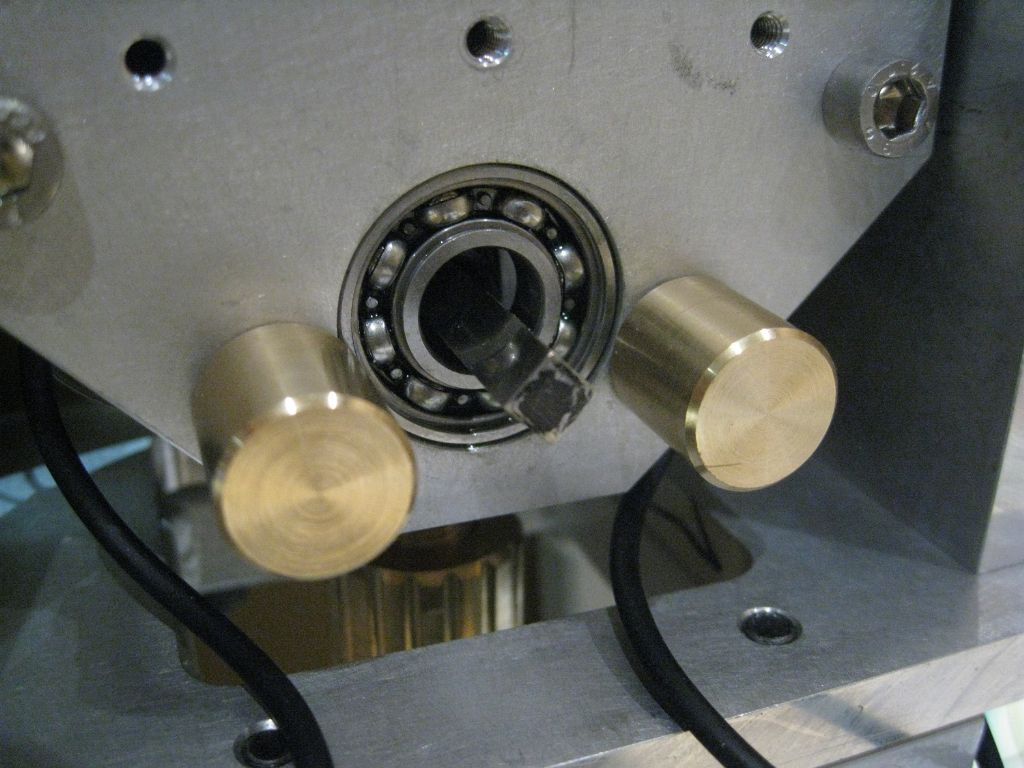

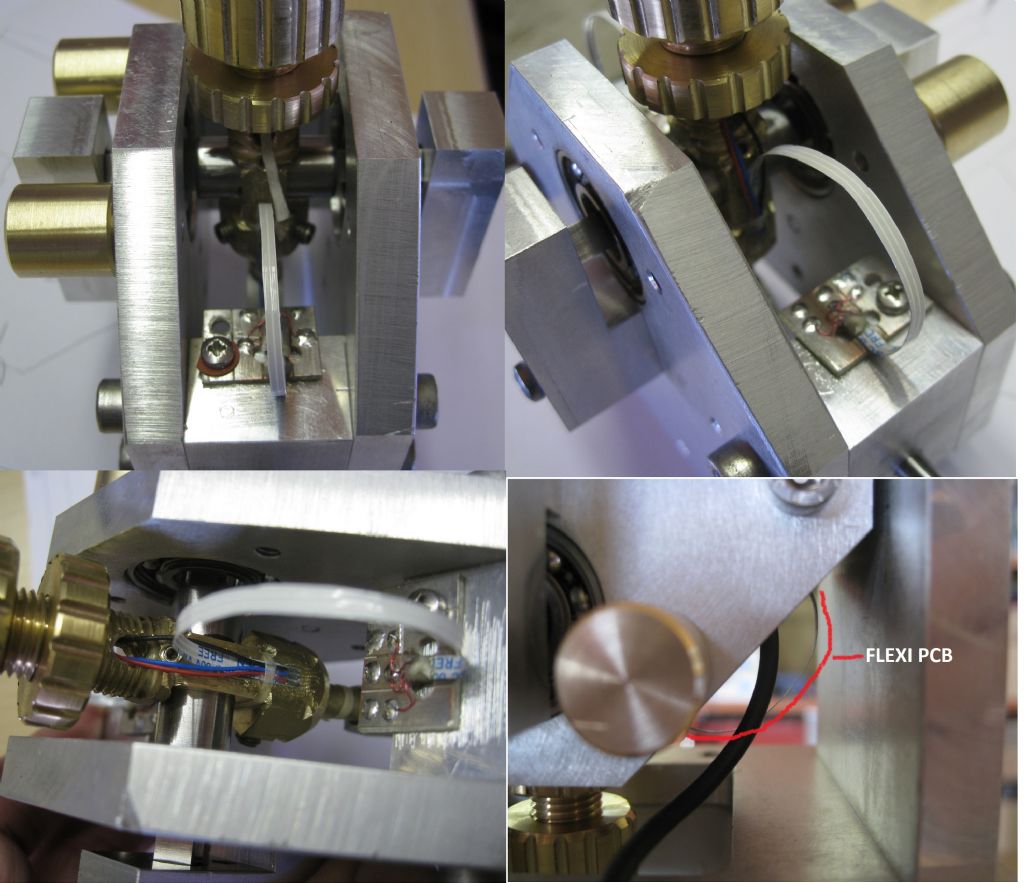

I opted for a knife edge style pivot – 6x6mm cobalt section 100mm long as the knife, riding on the inside race of a ball bearing. The bearing was loctited into its loose fit housing, with a ground shaft fitted through both bearings to locate and align the races. once cured, loctite was added to the balls in the races, the inner race rotated to spread the loctite, and left to cure with the shaft aligning the races.

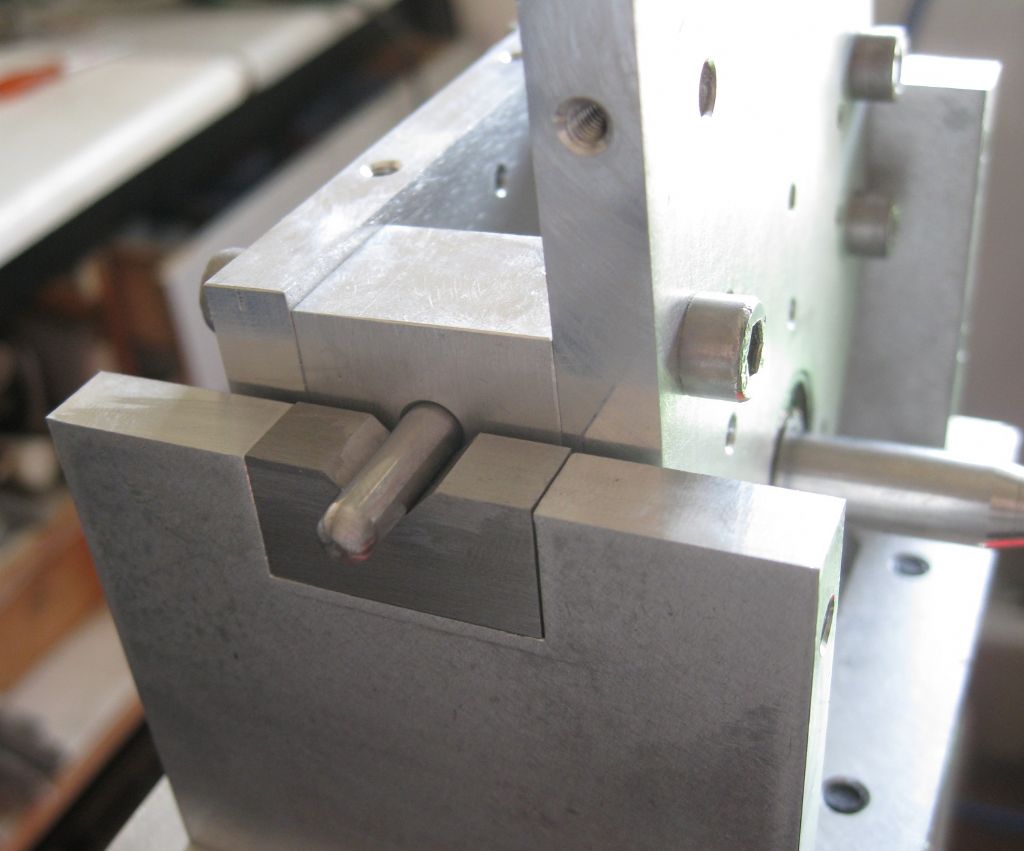

The head assembly with knife pivot can pivot laterally on hard steel pins in two V block, on the top support assy –

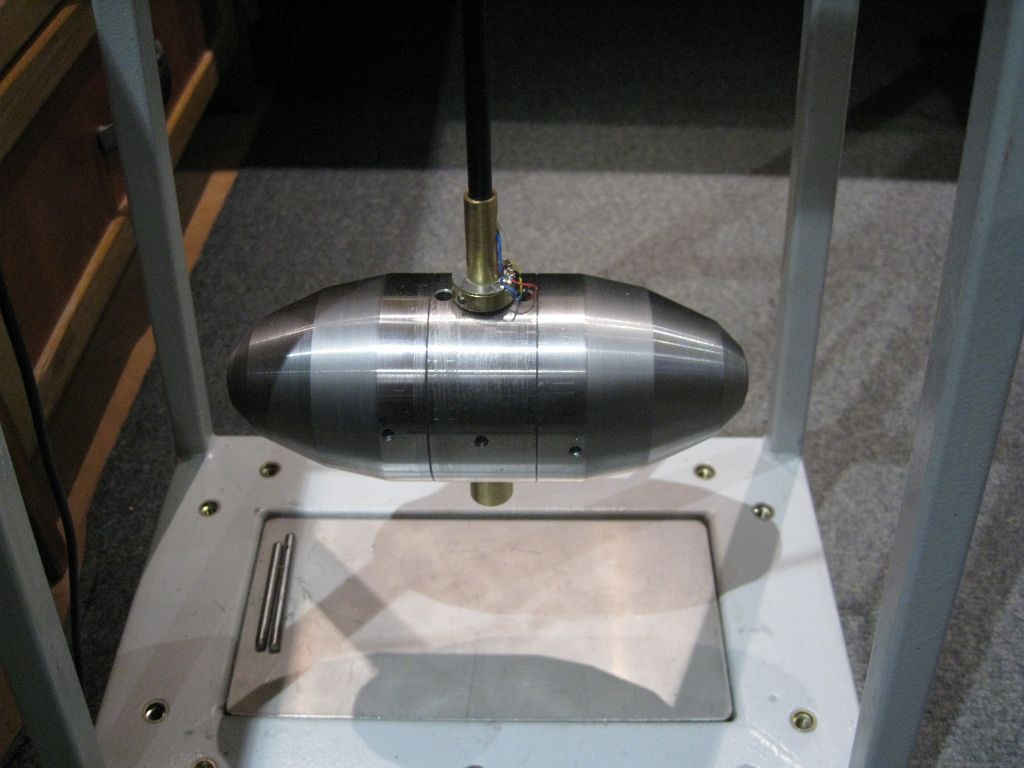

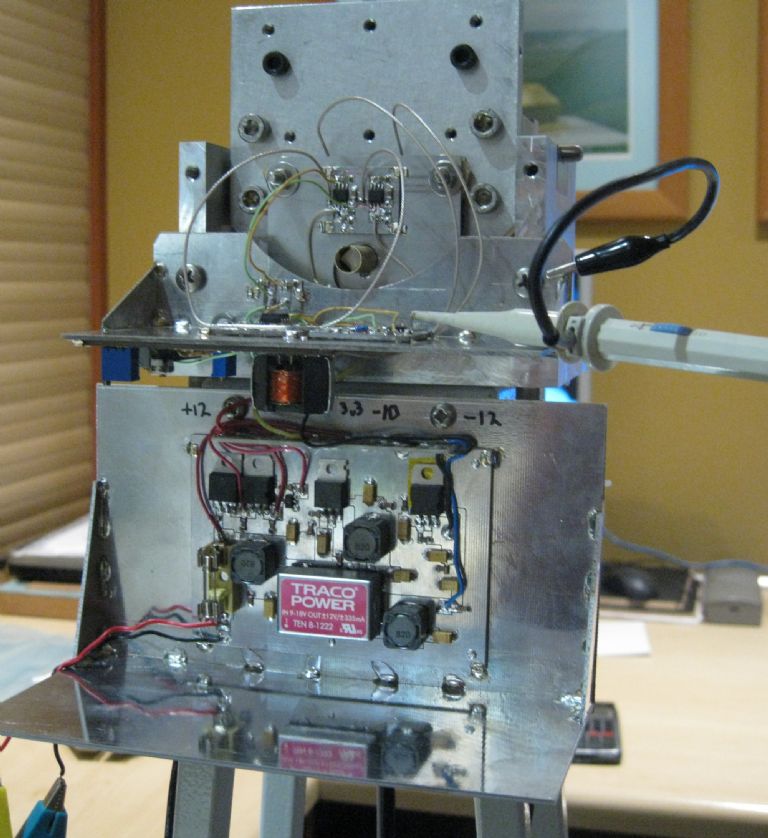

The frame is from sq tubing, with the base of 50x50mm tube, filled with lead shot, and the space between with a chunk of St-steel – 210x110x50mm (!) – base is about 15kg.

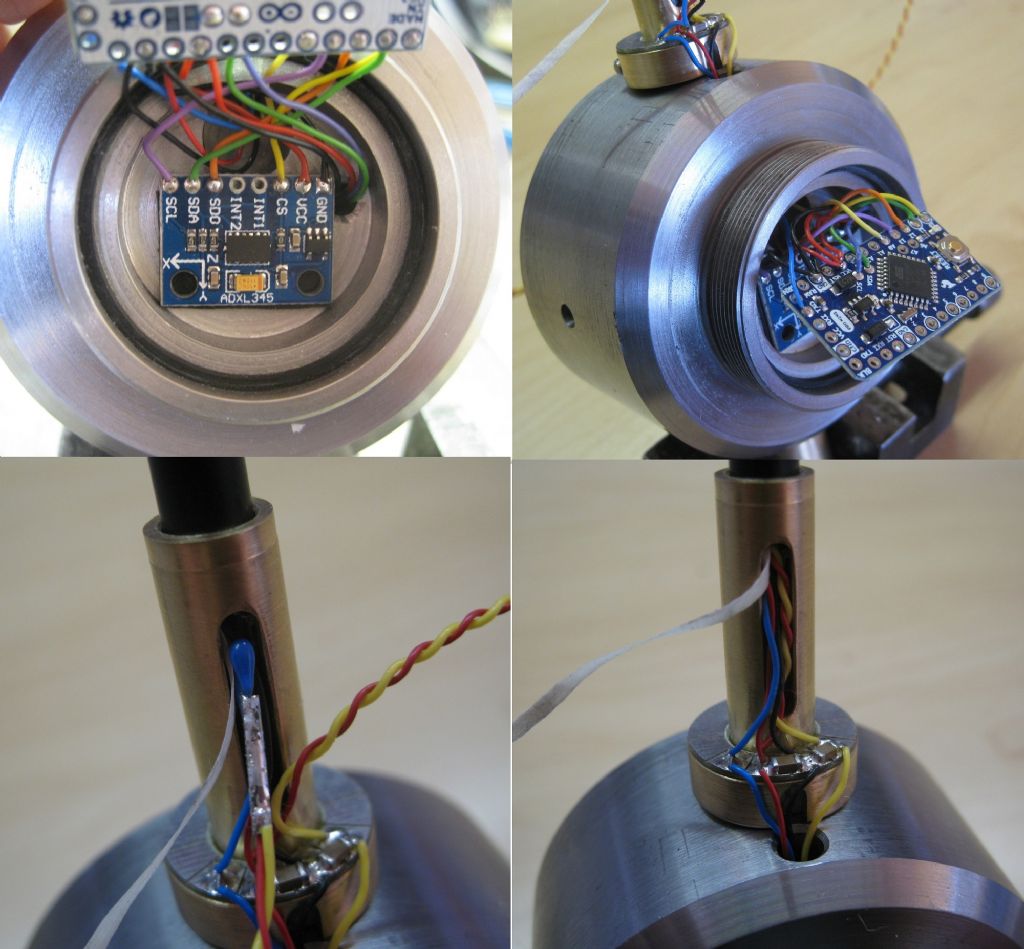

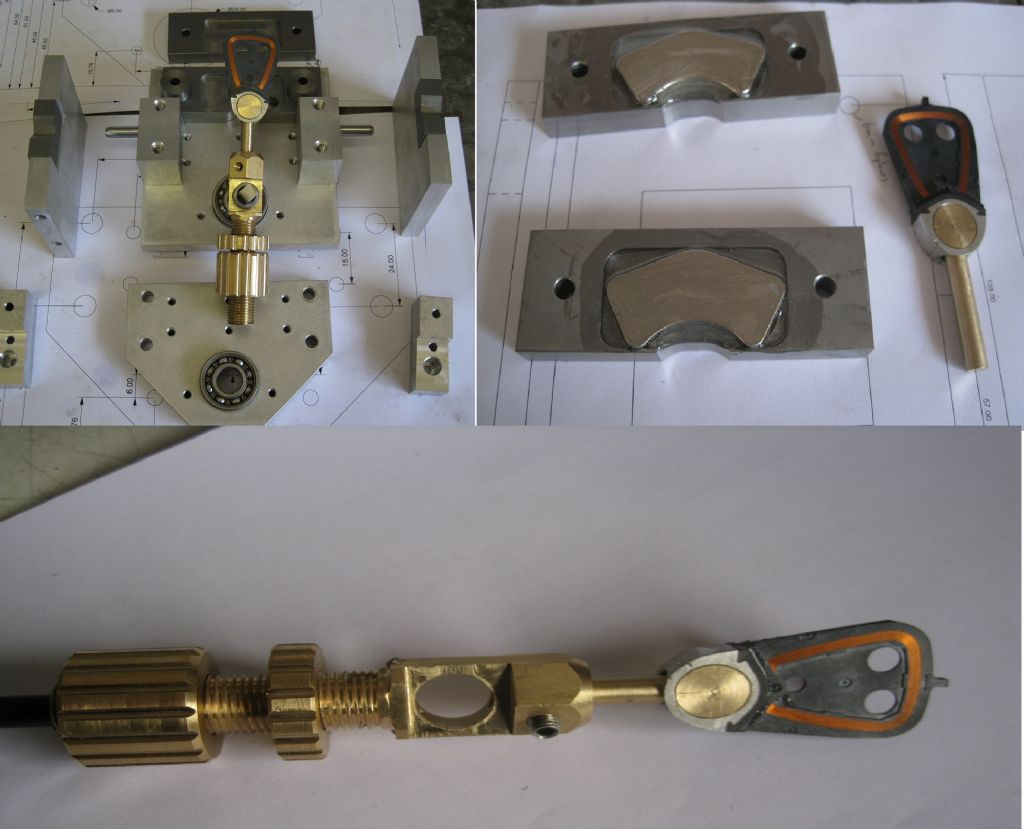

The bob is made in three parts that screw together so I can fit electronics inside – accelerometer, temp sensor, etc

The Pendulum rod is a carbon fibre tube, 7mm OD, 6mm ID. The wires to the bob run inside the tube and out the top at the pivot point so cable torsion is minimised. The wires come out the tube via thin (0.05mm thick) flexi PCB's.

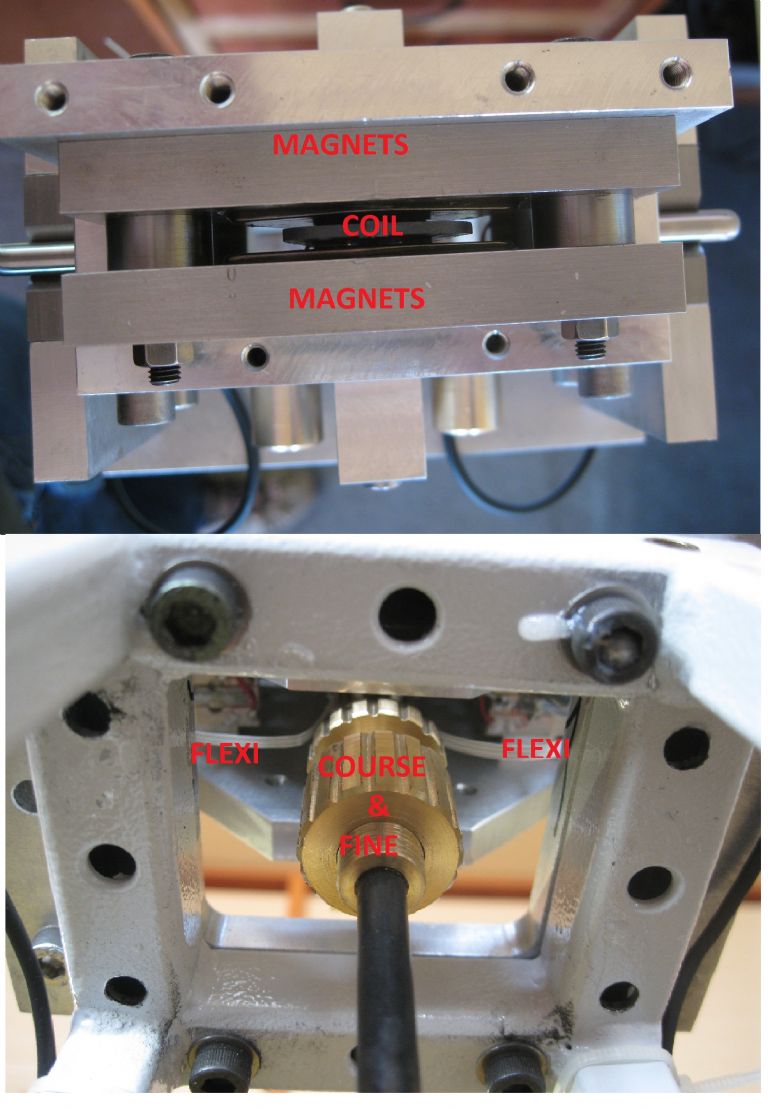

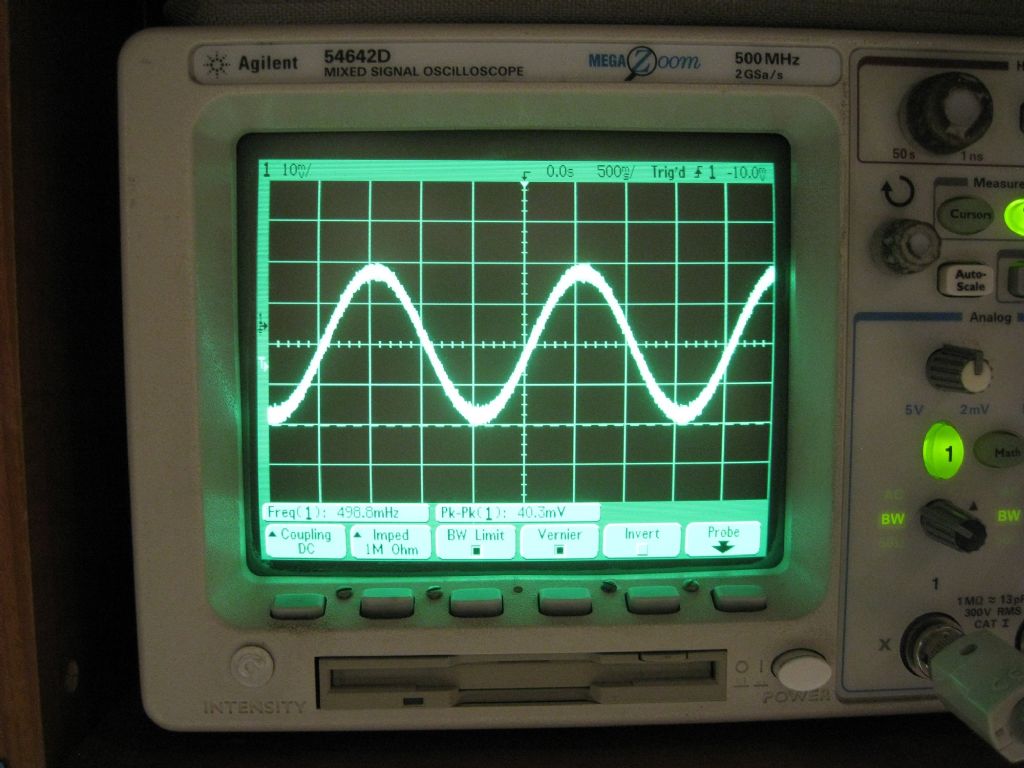

My intention is to provide a sinusoidal drive to the pendulum coil, not impulse. This drive to be phase locked to the pendulum motion, with the amplitude of the drive tuned through a Kalman filter to provide sufficient amplitude to just keep the pendulum amplitude the same, and thereby hopefully the period constant. The idea being not really to keep the amplitude the same but rather the total mechanical energy must be kept to a constant value. I am not driving for a specific period, but for constant , fixed energy. If the period is not exactly one second, I will gear this in software to drive an external clock at 'true' 1 second.

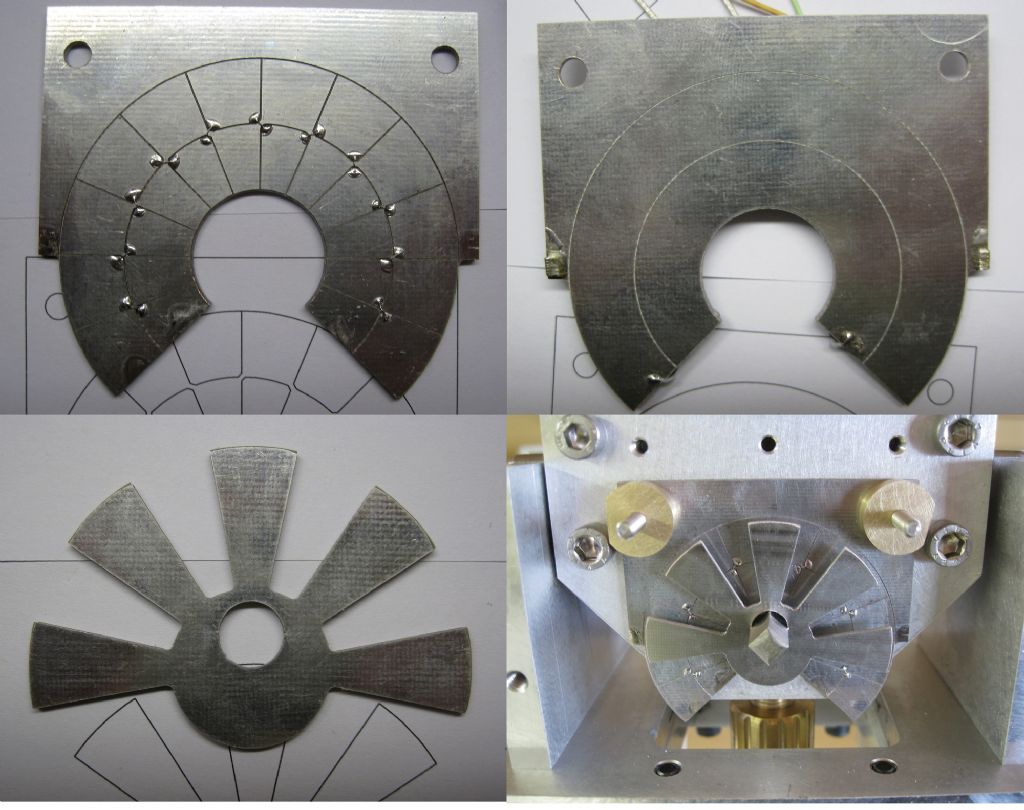

The drive to the pendulum is at the pivot end, not the bob end. It uses the drive coil from a small hard disc drive, and is sandwiched between the very powerful drive magnets.

This is the head assy and the magnets in there iron concentrators can be seen here..

Below is the pendulum tube top end, with the two screw adjustment weights – the larger weight is 15 grams, the smaller is 6 grams. The hole to the right of the small adjuster is where the knife will fit.

The magnets in place with the sandwiched coil, and the adjusters under seen here below

(edit- bugger this sofware! have to split the post again to many words….!!)

SillyOldDuffer.