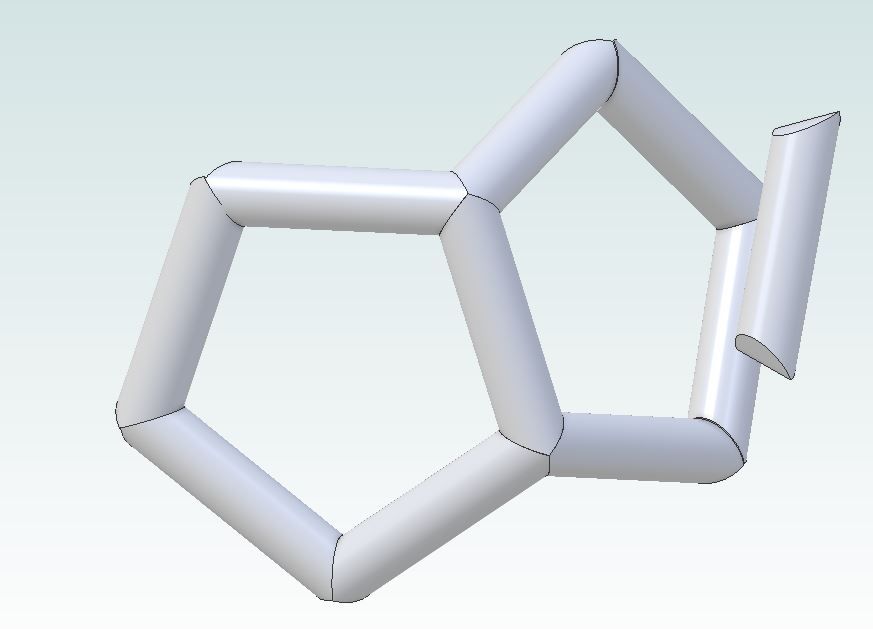

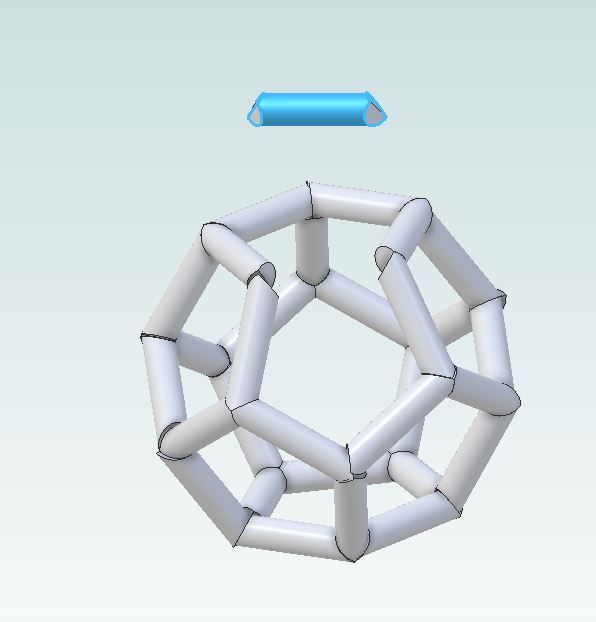

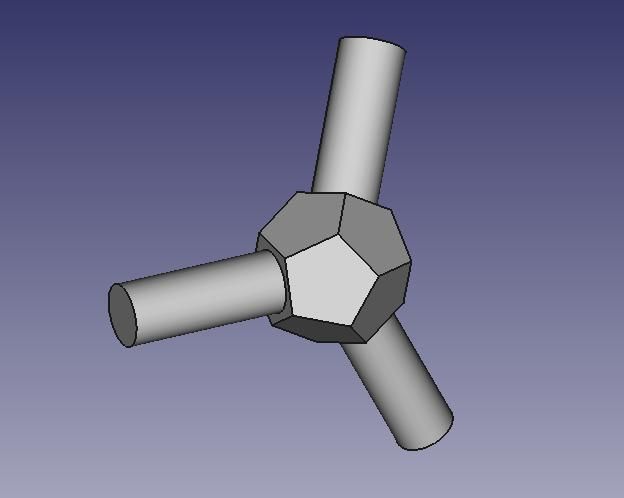

Just in case Andrew wants an extra-difficult, time-consuming and expensive alternative to Jason's excellent solution, it can also be done by making pentagonal dodecahedron end fixings. These are prettier than balls, and complete the motif!

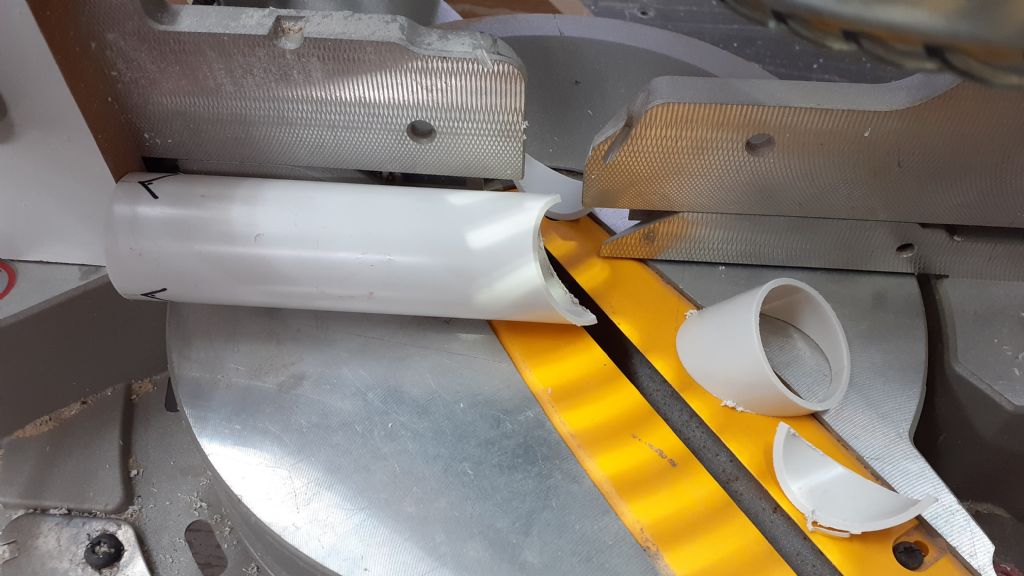

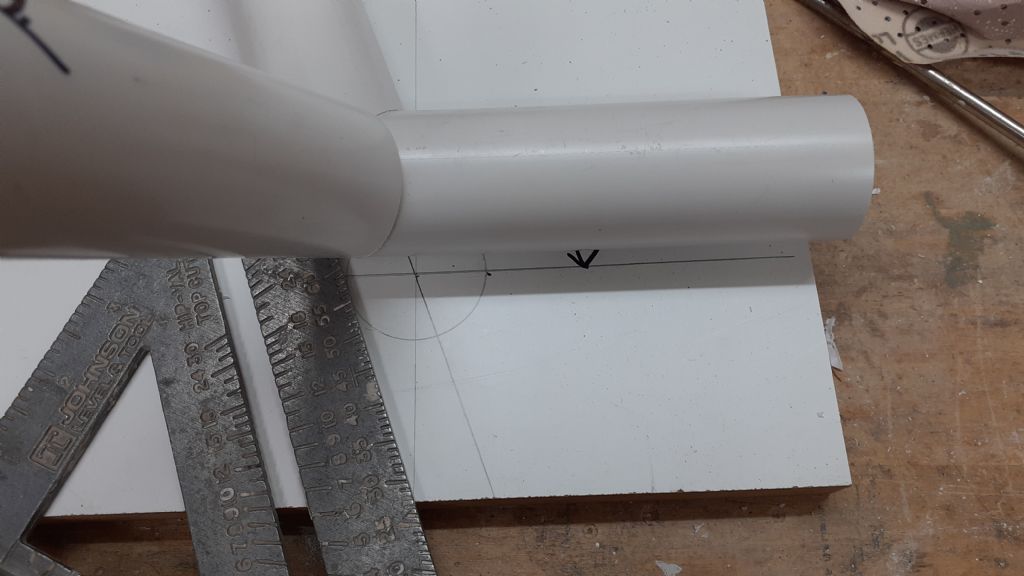

The method is easy, and the dodecahedron fixings could be threaded rather than welded.

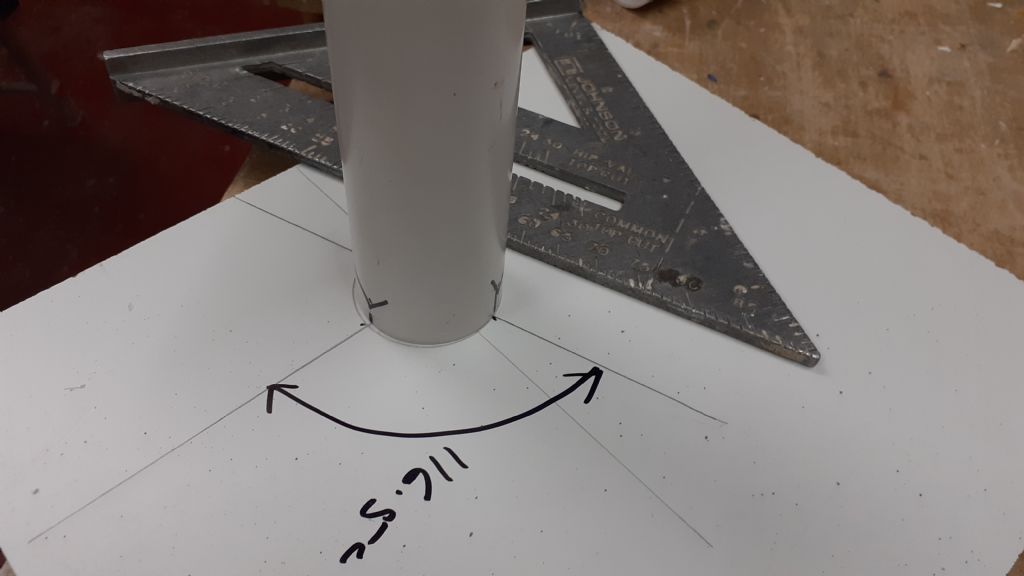

All that's needed is 20 steel dodecahedrons big enough to join 2" diameter steel pipe, bored on 3 faces. A mere detail I'm sure! So the next challenge is "How can I make 20 fist-sized steel dodecahedrons in a home workshop?" (With mill, lathe and the usual hand tools.)

Dave

PS. On a CAD note, FreeCAD did better than Solid Edge on this particular problem. As far a I can see SE doesn't have a tool for creating dodecahedrons, so they have to be developed from first principles – hard work. FreeCAD has an add-on workbench for making pyramids and polyhedrons, so they're just a button press. Trying new things caused the usual CAD grief, which is the software not working quite as expected. It's easy when you know how!

Edited By SillyOldDuffer on 29/03/2023 11:28:55

JasonB.

JasonB.