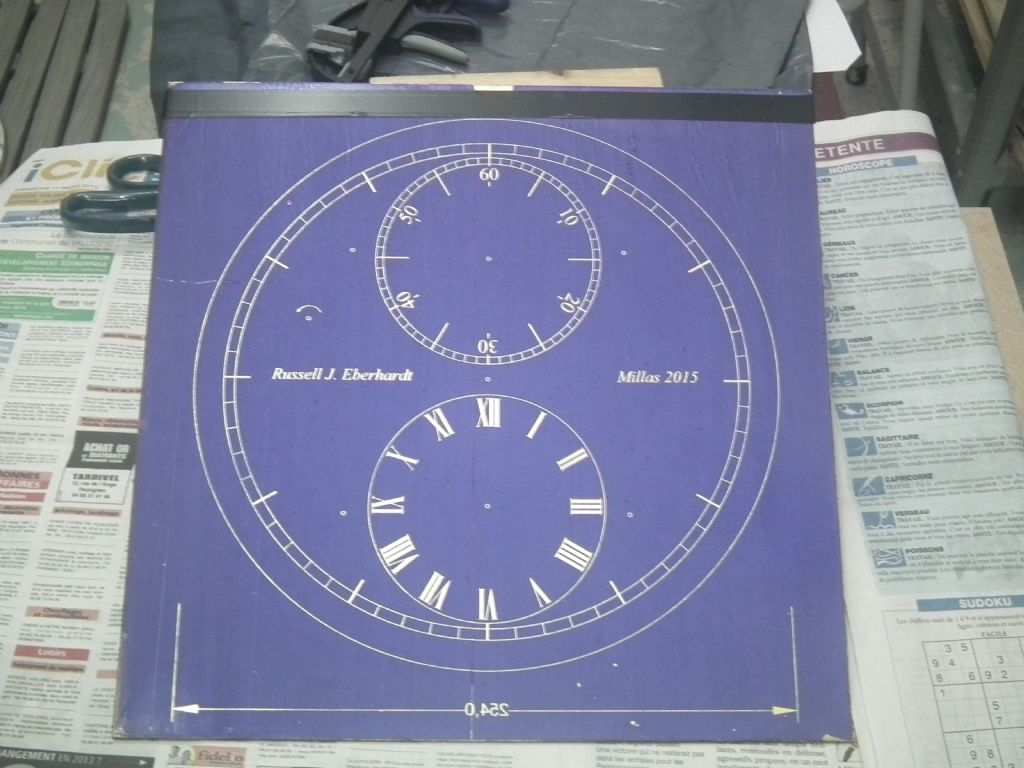

Some time ago Mr. Russell Eberhardt posted that he intended to build the month going version of the John Wilding regulator but fitted with ball bearings at all pivot points and invited comment from anyone who had built this clock.

Some time ago Mr. Russell Eberhardt posted that he intended to build the month going version of the John Wilding regulator but fitted with ball bearings at all pivot points and invited comment from anyone who had built this clock.

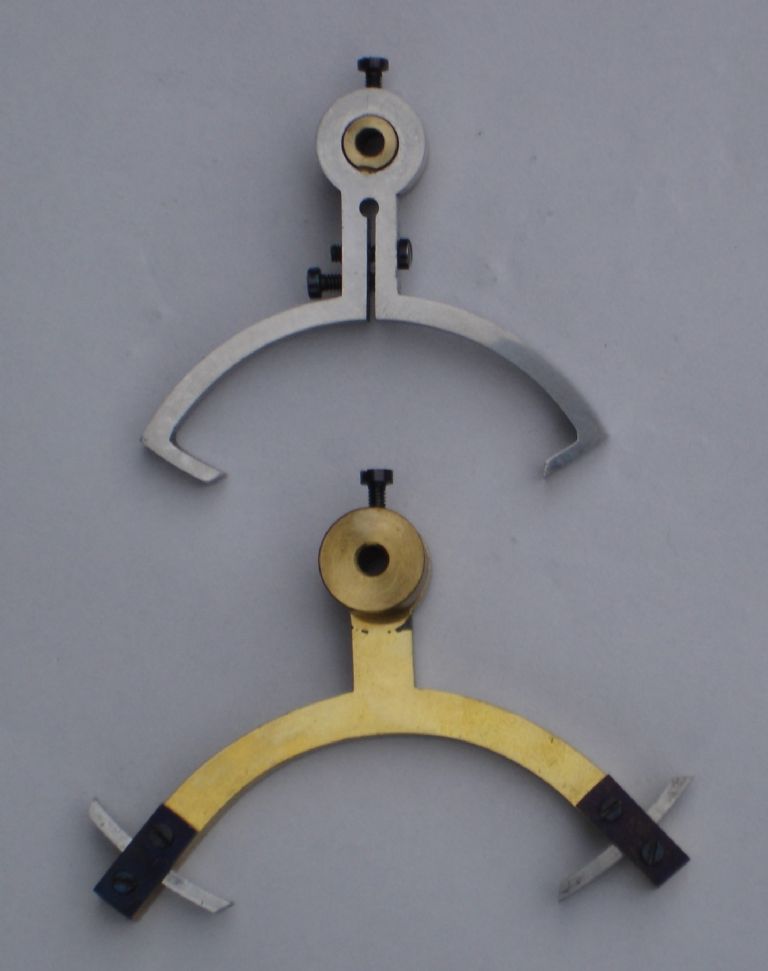

In 2002 I built the eight day going version of this clock as described in Mr. Wildings book except for the maintaining power spring (q.v.) I had no problems building this clock and it kept time to two or three seconds a week on a 5lb driving weight. At a later date I added jewels to all pivots except for the hour hand arbor ,as this carries no load, and the winding barrel arbor and front pivot of the centre arbor as no jewels were available for these points. At the same time I replaced the solid escape anchor with the Vulliamy type.These modifications enabled the driving weight to be reduced to 4lb with the same time keeping.

A couple of years later I built the same clock for a friend but this time with an escapement anchor spanning seven and a half teeth as I had read in the literature that a `Square` escapement spanning seven teeth was the optimum form of the dead beat escapement. This clock gave the same performance but required a six lb driving weight.

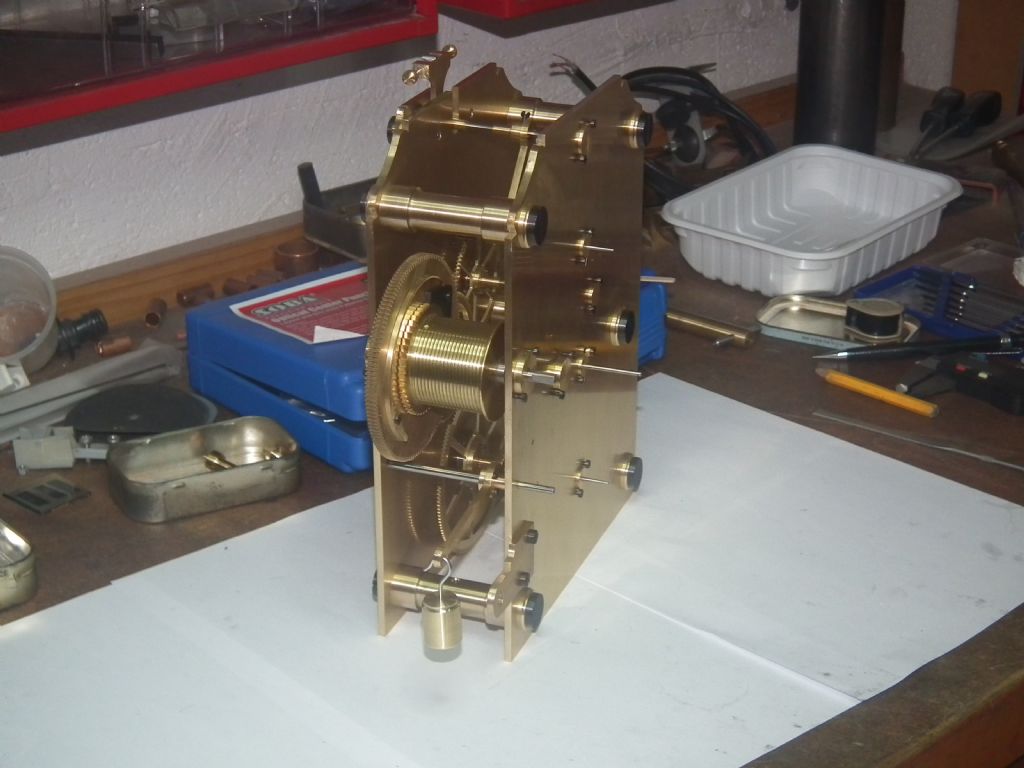

After reading the discussion of Mr. Eberhardts proposal I fitted ball bearings to the winding barrel arbor and the front pivot of the centre arbor.. These are flanged shielded bearings. The winding barrel arbor bearings were 0.5" o/d and 0.25" i/d and a light push fit in the frame plates and retained with collars and 10 B.A screws and the centre arbor bearing was 6mm o/d and 3mm i/d and made a light press fit in the frame plate I first tried the ball bearings as supplied and then with the grease flushed out but could detect no difference in the pendulum swing. I then ran a drop of clock oil into each bearing as an anti-corrosion measure.These modifications enabled the driving weight to be reduced to three and a half lb.and the time keeping was unaffected.

May I offer the followings comments on the month going version for consideration.

Ball bearings are cheap and easy to fit. The jewels in my clock were imported from `The Swiss Jewel Company` in the U.S.A who have a minimum `shipping` order of 100$ which makes the price prohibitive unless more than one clock is being built, as in my case. The maintaining power spring in my clock is gauge plate 18 s.w.g.(0.048) thick and 0.070 wide. As the stiffness of this spring increases as the cube of its width it would not need to be much wider to suit the increased weight needed to drive the month going version and would be much simpler than Mr. Wildings bolt and shutter arrangement. The pin at the top of the great wheel in the photo limits the relative turning of the maintaining ratchet to the great wheel to four teeth, which is adequate and avoids over-stressing the spring.

For anyone building the clock from  scratch, cutting the winding barrel right handed would cause the driving weight to move away from the pendulum as the weight descends as originally intended and may permit the fitting of some sort of stop-work which is absent form the present design.

scratch, cutting the winding barrel right handed would cause the driving weight to move away from the pendulum as the weight descends as originally intended and may permit the fitting of some sort of stop-work which is absent form the present design.

I hope that these comments are helpful to any future constructors of this regulator.

John Parslow

Russell Eberhardt.

Russell Eberhardt.