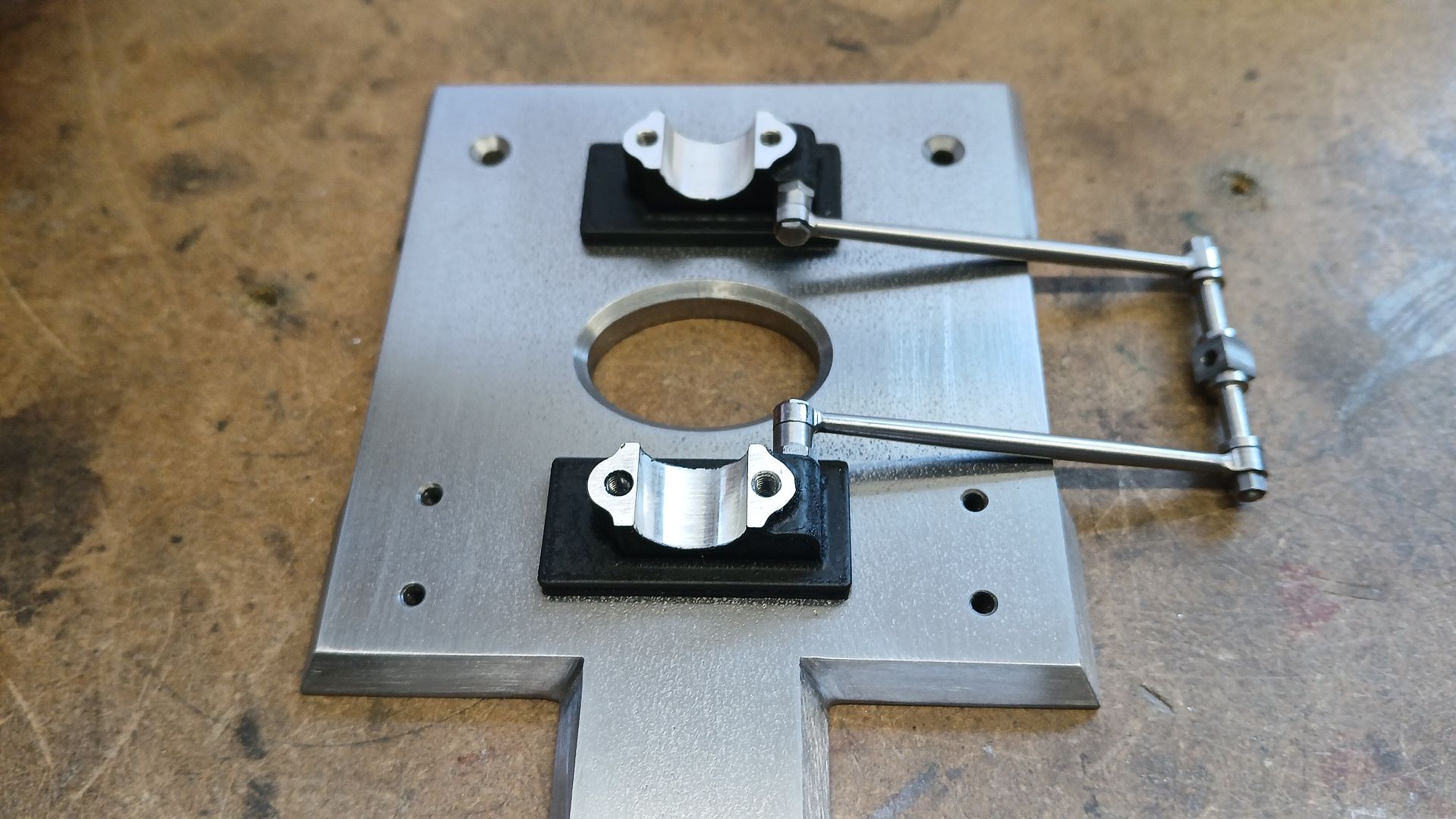

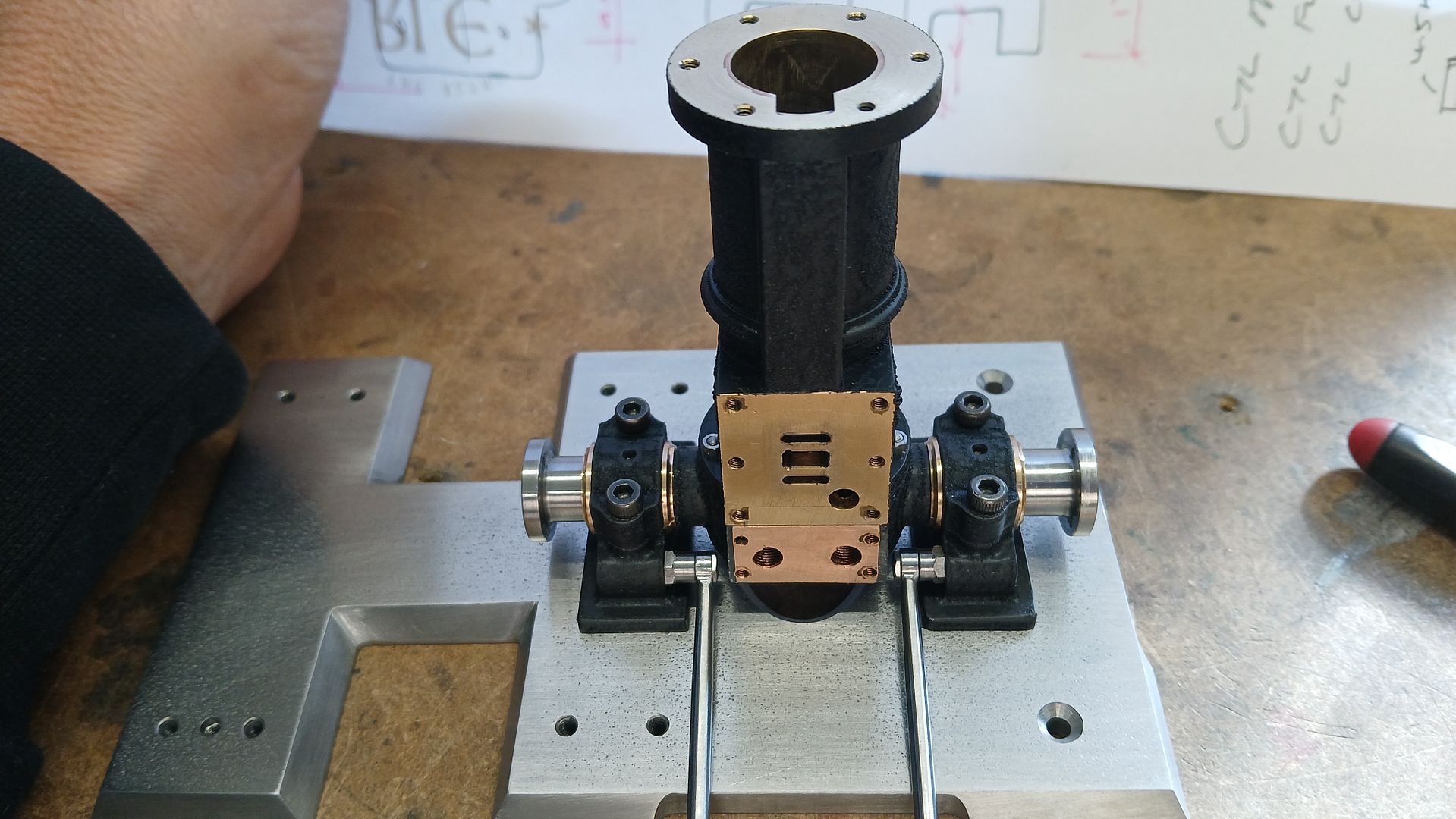

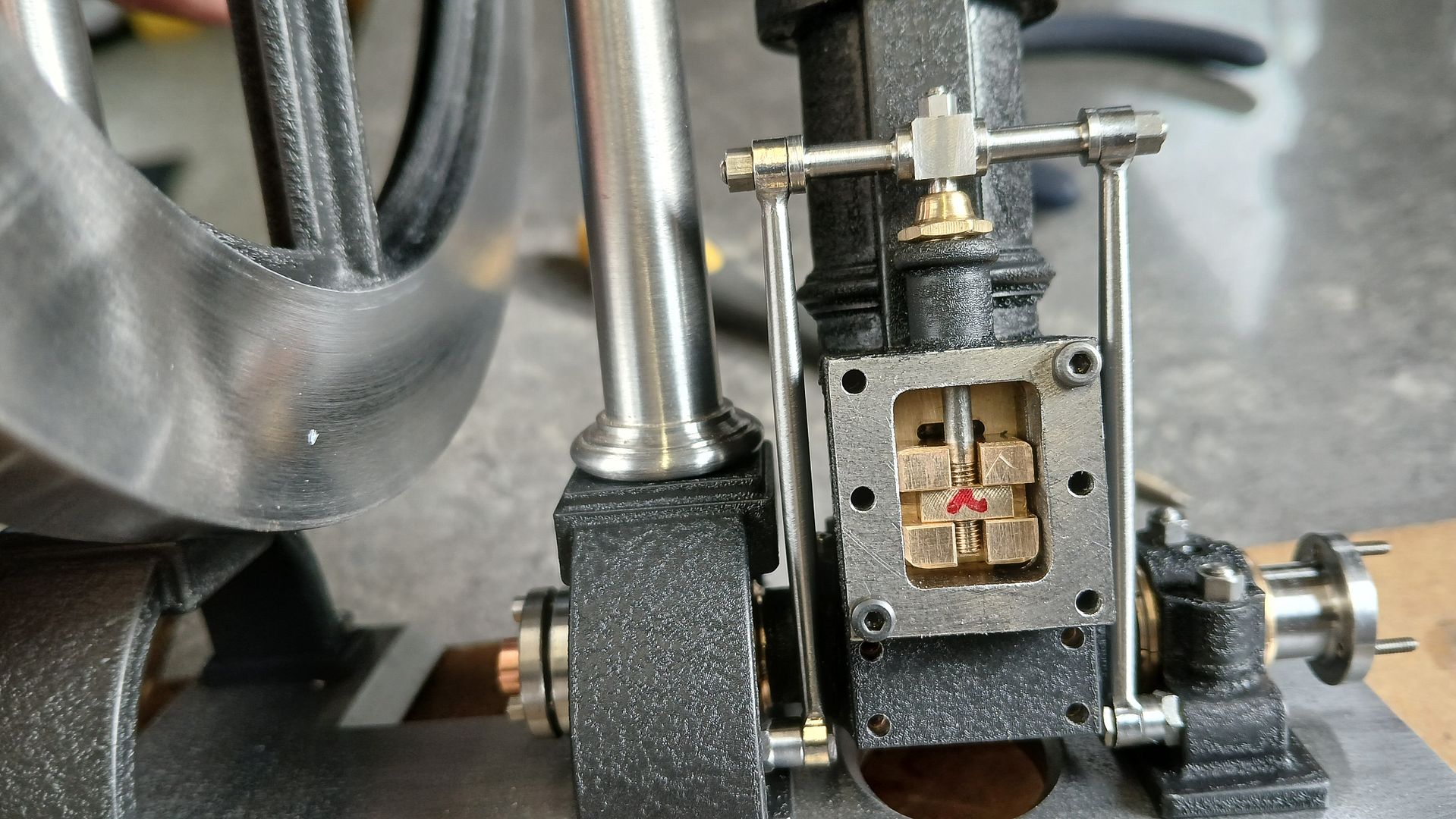

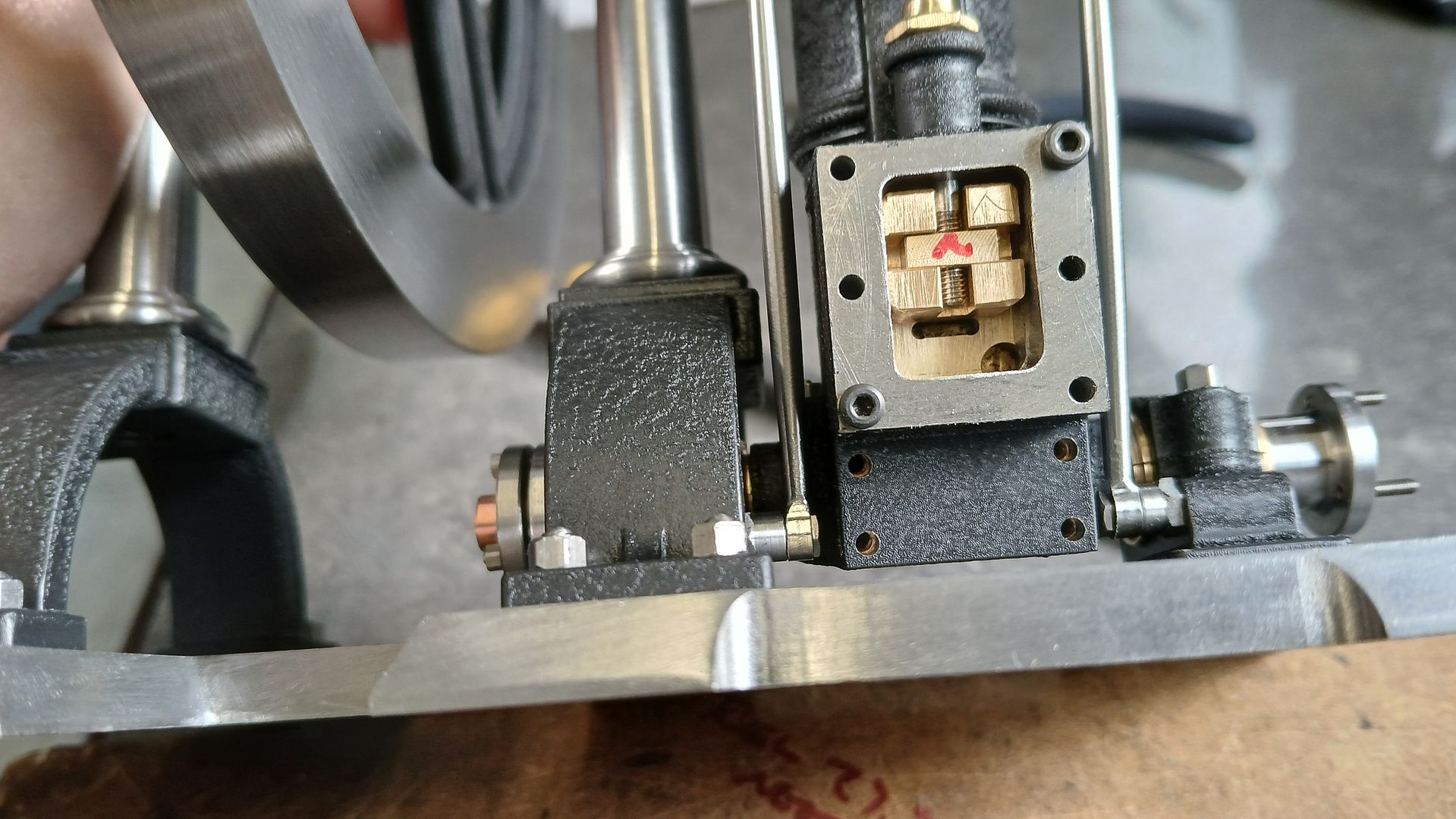

The original model had a valve chest with an integral cover and a separate gland and surround, you could also see were the passages had been drilled and plugged on the trunion below the chest. I went for the more traditional rectangular “box” and separate cover and also included a lower lip to cover the passages into the edge of the trunion.

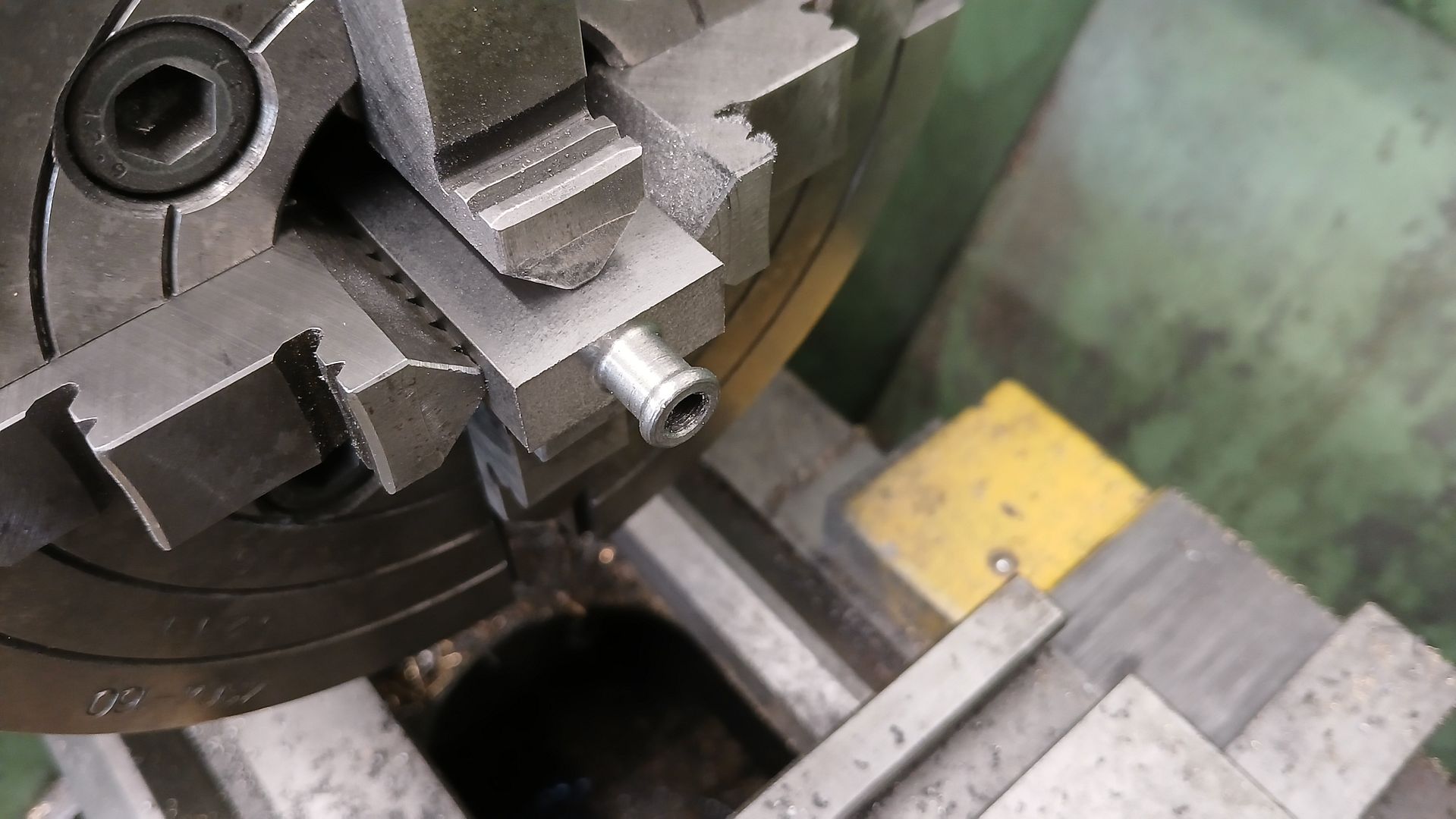

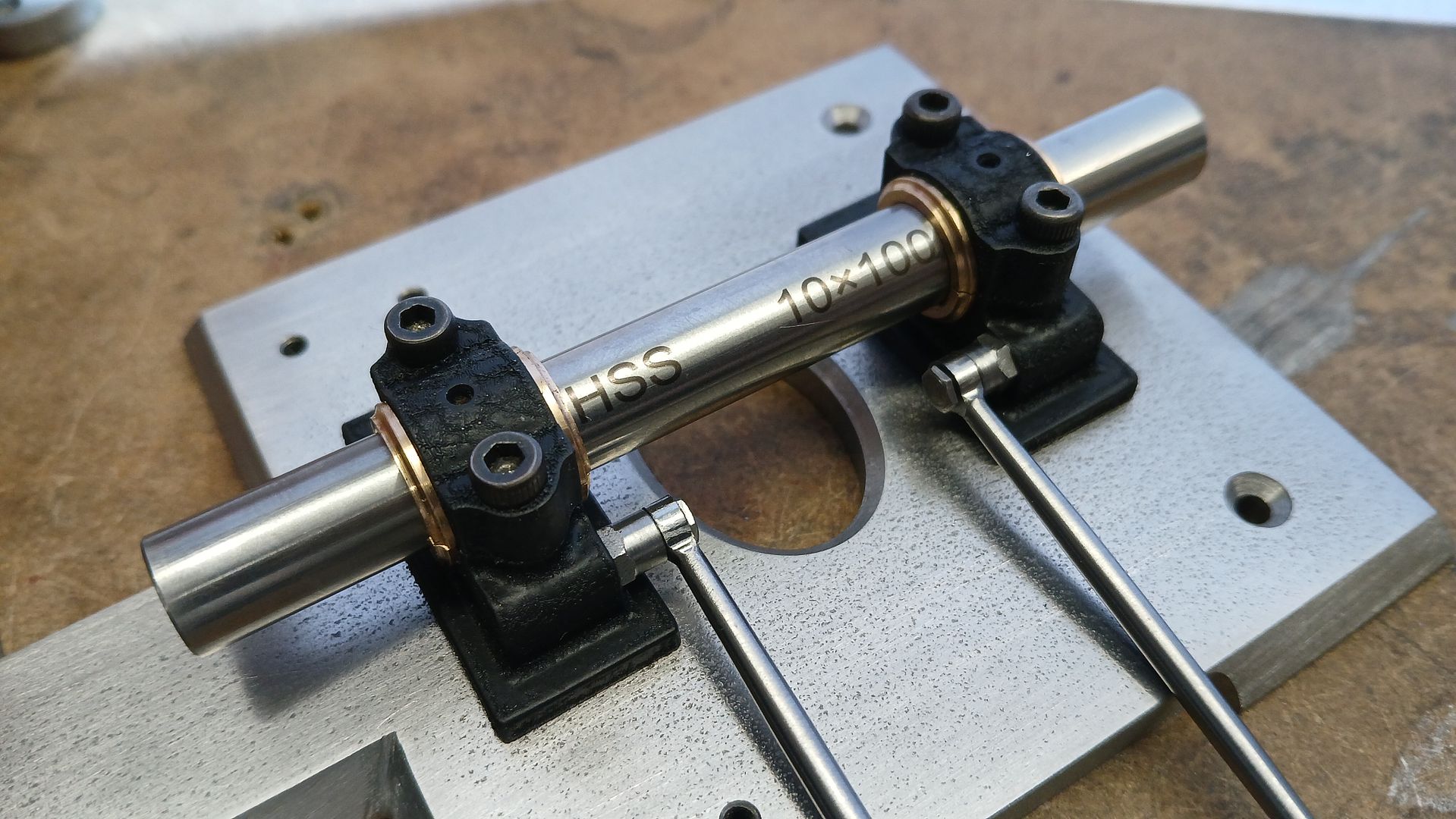

After milling a lump of cast iron down to overall size it was set up in the 4-jaw to turn the neck of the gland followed by drilling for the valve rod and tapping for the gland.

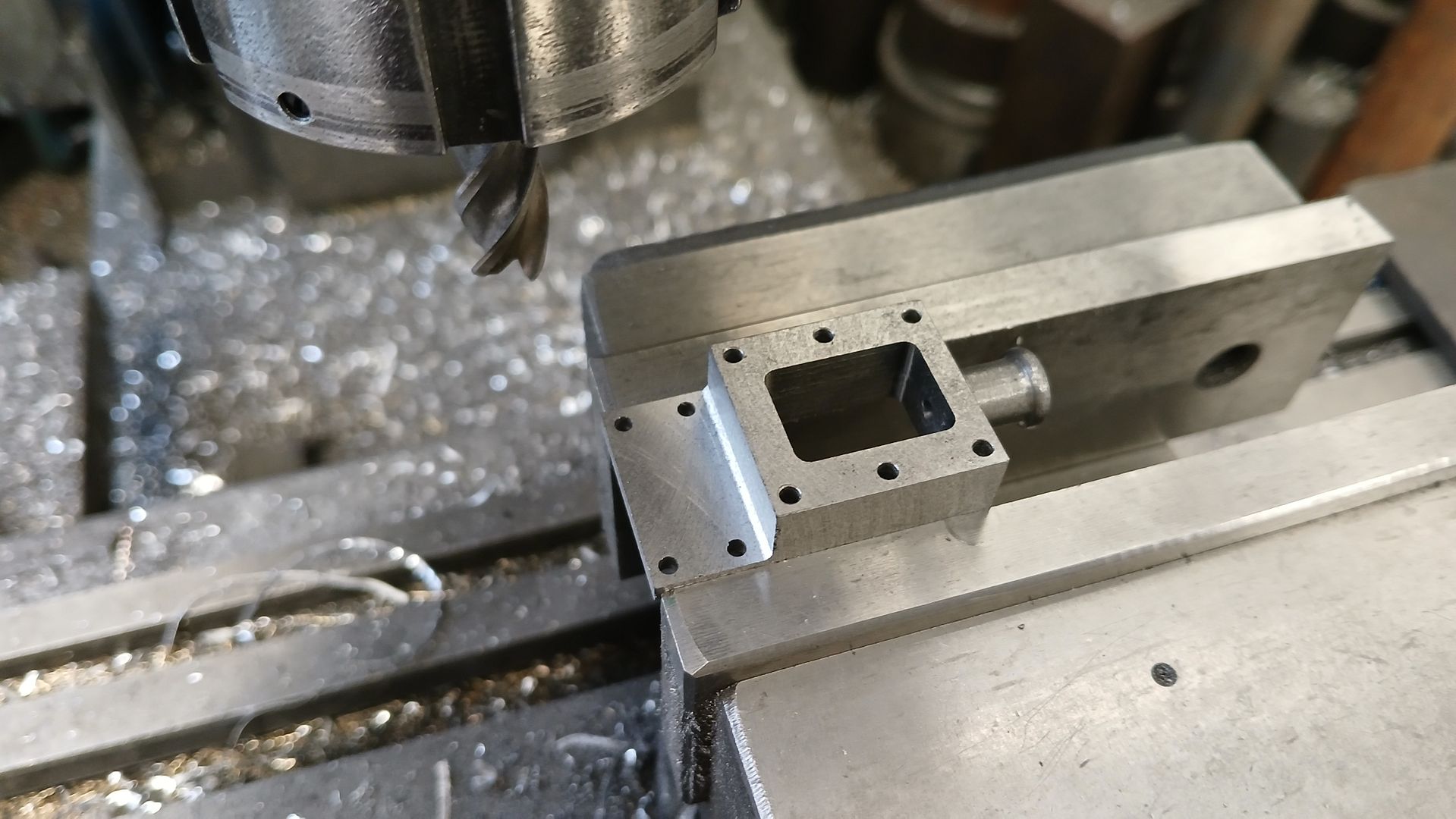

Then back to the mill to machine out the cavity, drill the stud holes and lastly mill the lip for which I used a 6mm x 1R cutter to leave a small fillet.

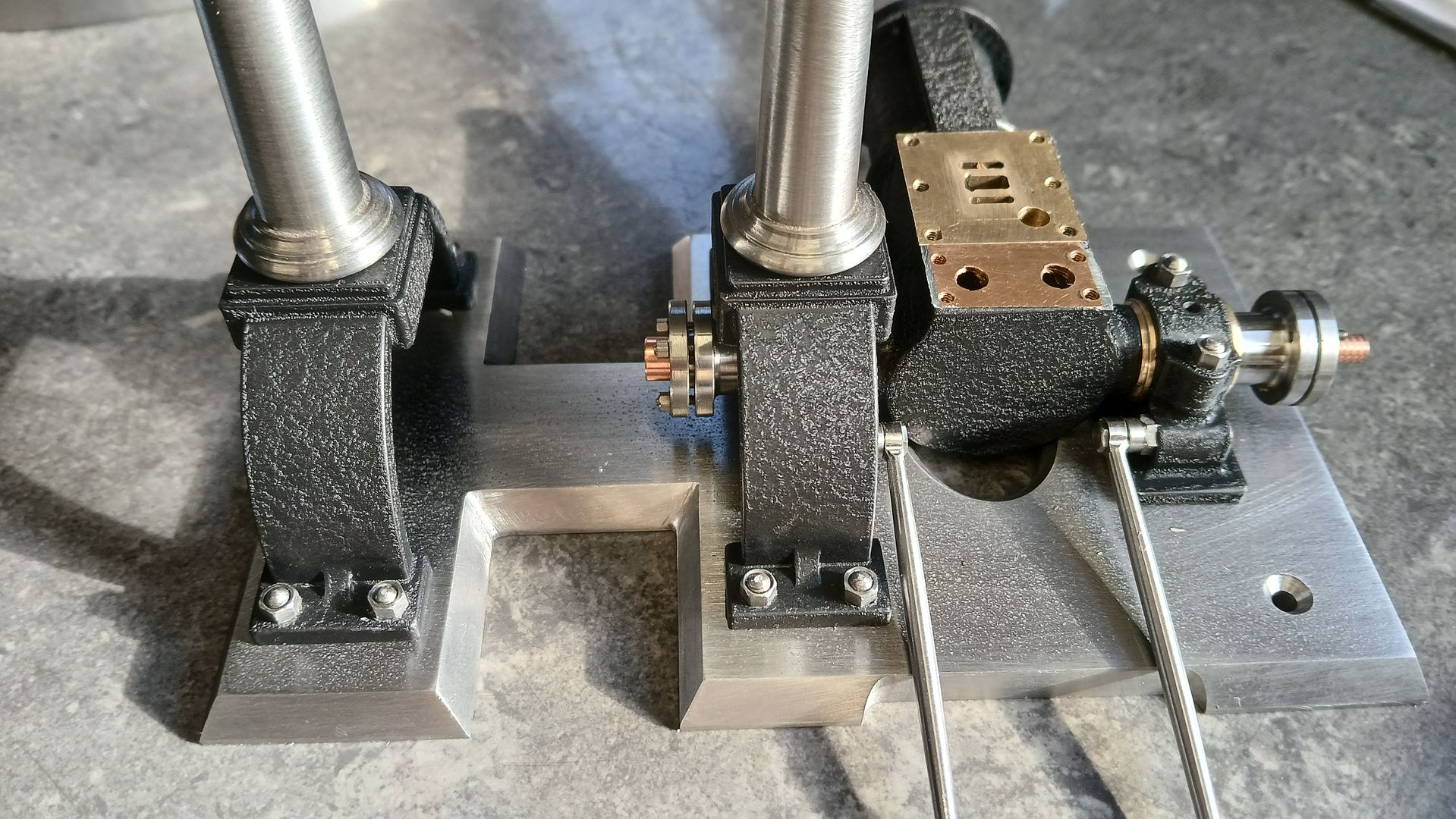

The remaining parts such as cylinder end cover, glands, rods, piston and valve yoke were all fairly straightforward turning with a bit of milling so I did not take photos of them but once they were made I had enough bits to give the assembly a test. No gaskets, rings or gland packing but things looked promising.

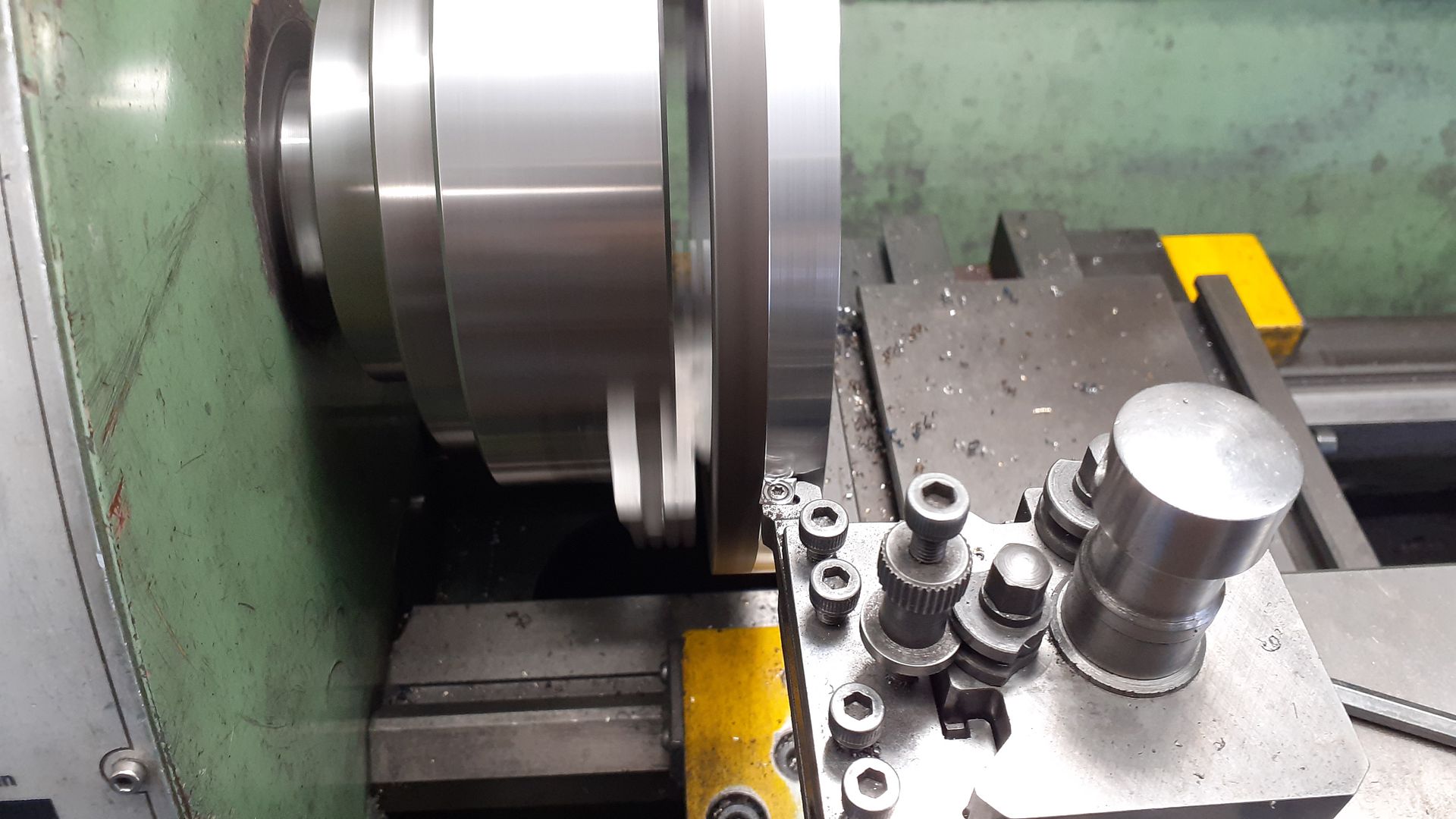

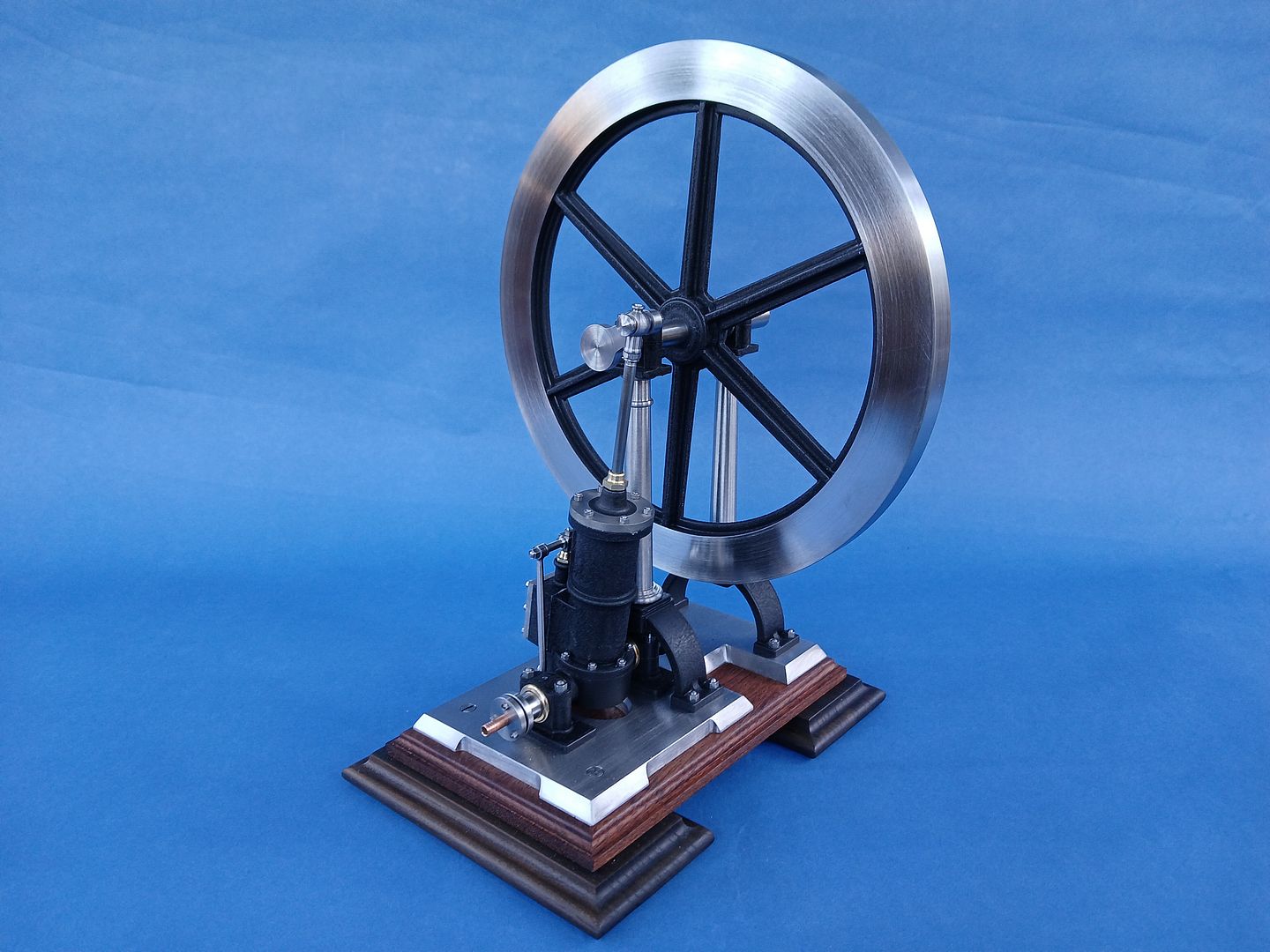

As mentioned earlier I went for a slightly deeper and wider flywheel rim to help with low speed running. The rim was turned a little oversize from some thick wall steel tube.

I opted for round stock to make the spokes, facing to length and then adding ctr drill holes at each end as I thought I might do the tapers by turning. The “+” section was machined using a face mill taking advantage of the 0.8mm tip radius to leave a fillet in the corners. After that I ended up by just holding the spokes at an angle in the vice and cut the tapers.

The outer end of the spokes were notched to fit over the web that runs around the inside of the rim. A two piece hub has slots milled to accommodate the other ends when it was sandwiched over them. I silver soldered it all together in two heats, the first to join the spokes to the rim which allowed the rim to expand and then cool without the inner end of the spokes constraining it. Then a second heat to solder them into the hub.

The rim joints filled very nicely with solder with only one needing a touch of JB Weld. The hub joints were not so close so there were a couple of gaps in the solder that needed some more JBW. On mounting the flywheel in the 4-jaw again there was a very slight movement to oval and also a slight bit of pringle going on but it only needed about 0.2-0.3mm off to get a full cut which was within what I had allowed. The hub was bored to a nice firm fit on the crankshaft and later broached for a gib head key.

That’s all my construction photos so all that is left is a video of the test run. I have taken some more photos of it being put back together after painting which should be useful for those that have shown interste in making something similar but they will have to wait until next time.

Wade Beatty.