Has anybody modified this design to use piston rings?

I have had two attempts to get a piston / cylinder combination with good compression. After hours spent hand lapping with the technique described by Ramon in Model Engine Maker and following Geoffs advice I achieved what I thought was a reasonable fit. Not as tight as a commercial engine but there was a plop when flicking it over. However as soon as I tried to start the motor, using a starter it quickly lost compression.

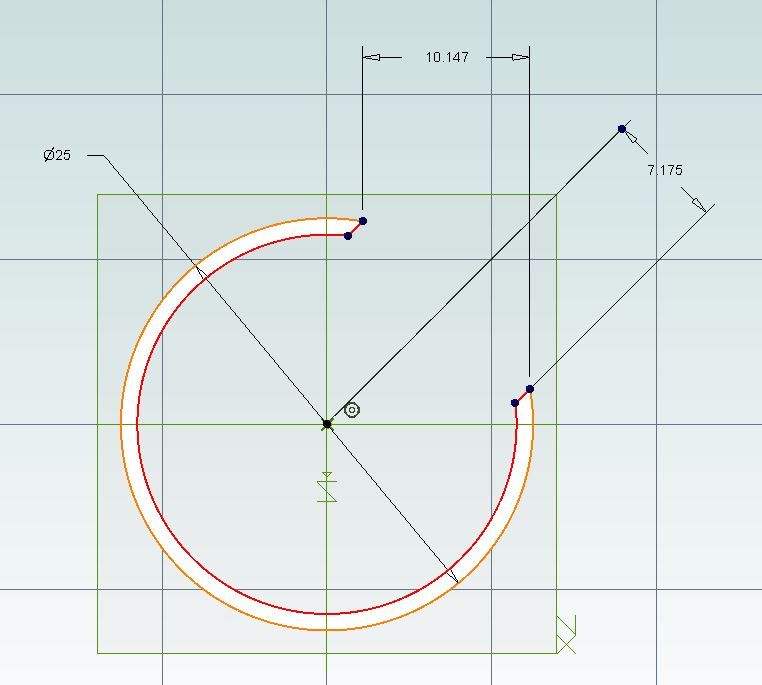

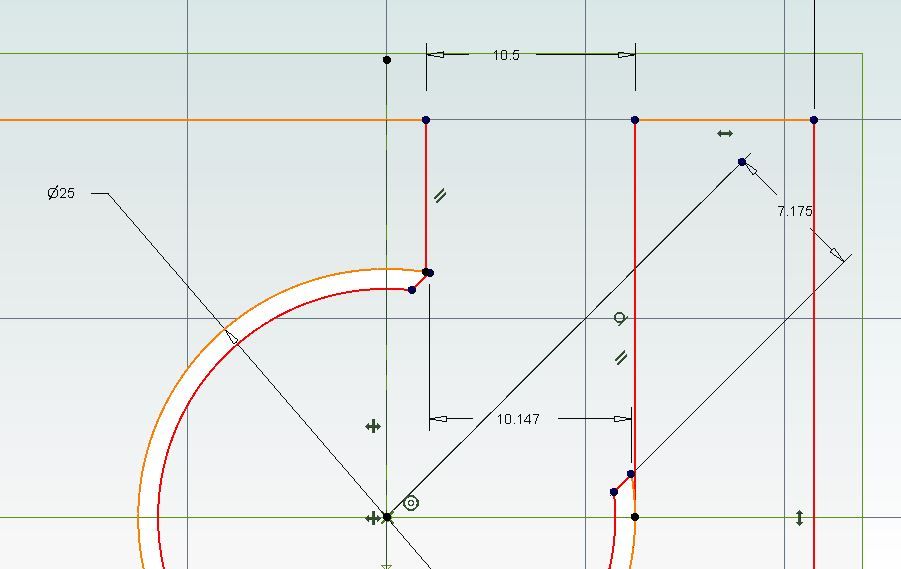

In desperation, I have just turned up a piston ring out of cast iron. It is 0.08 mm larger diam than the cylinder diameter, 2mm wide and 1.3mm thick. it was split with a diamond cutting wheel.

A groove was turned in a discarded undersize piston about 3mm from the piston head, 2.1mm wide and 1.7mm deep.

The ring was easily expanded by hand to fit in the groove and then the piston was slid into the cylinder and the ring pushed into the groove whilst pressing down.

A bit of lapping with 1200 paste was needed but now it feels good.

I need to make a new gudgeon pin before reassembling and testing tomorrow.

Any observations why this should not work?

Peter

Anders Be.