Cylinder Head

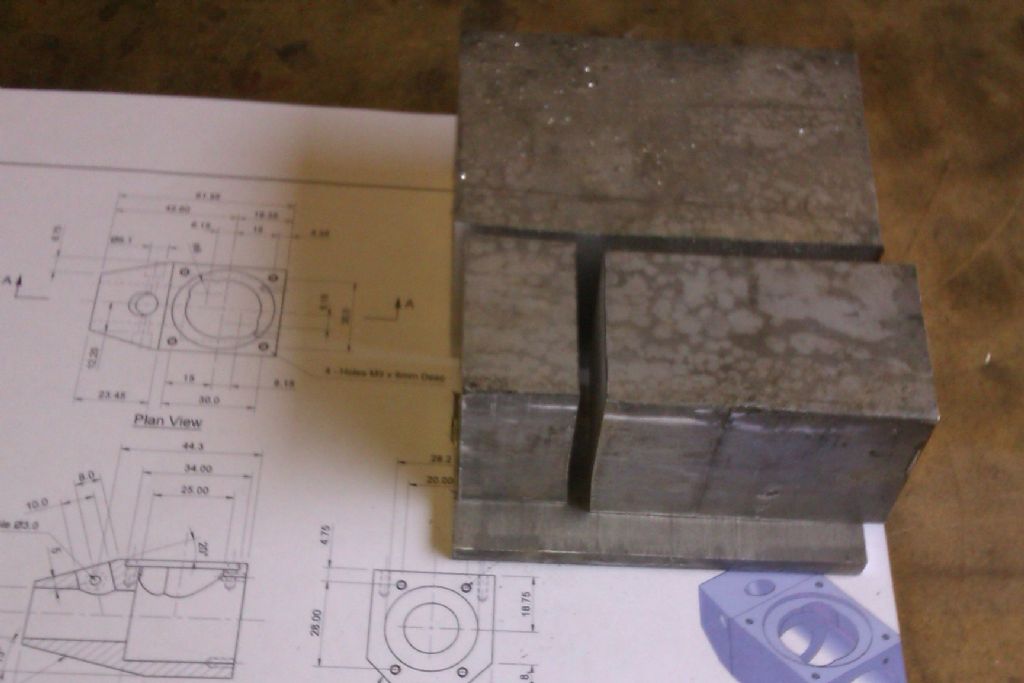

Before starting I should point out that I have deviated from the drawings slightly, nothing major only cosmetic changes.

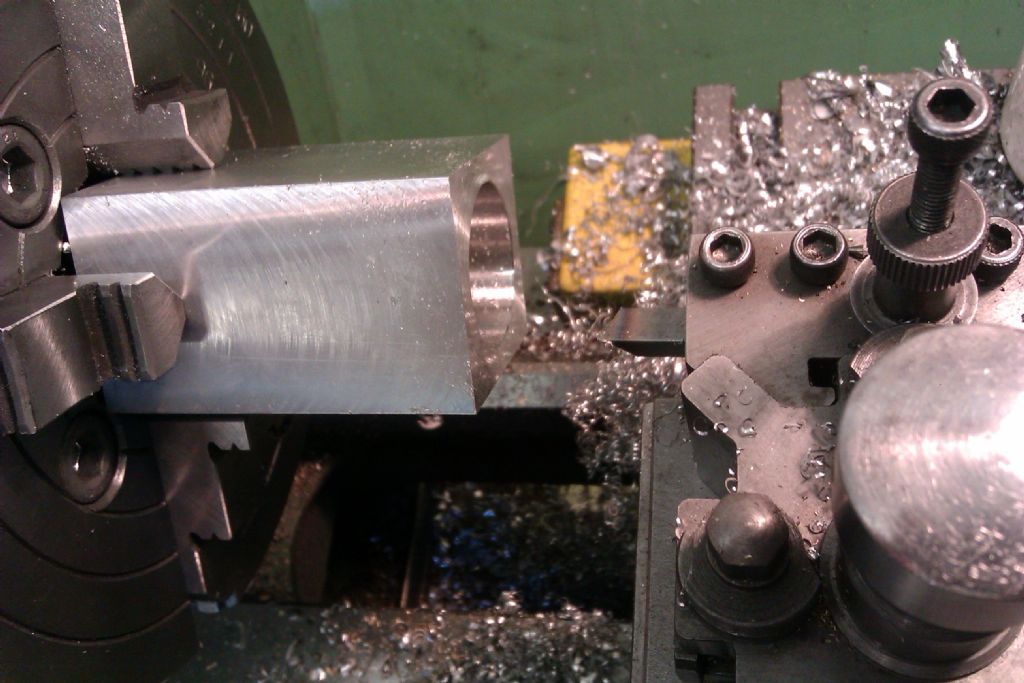

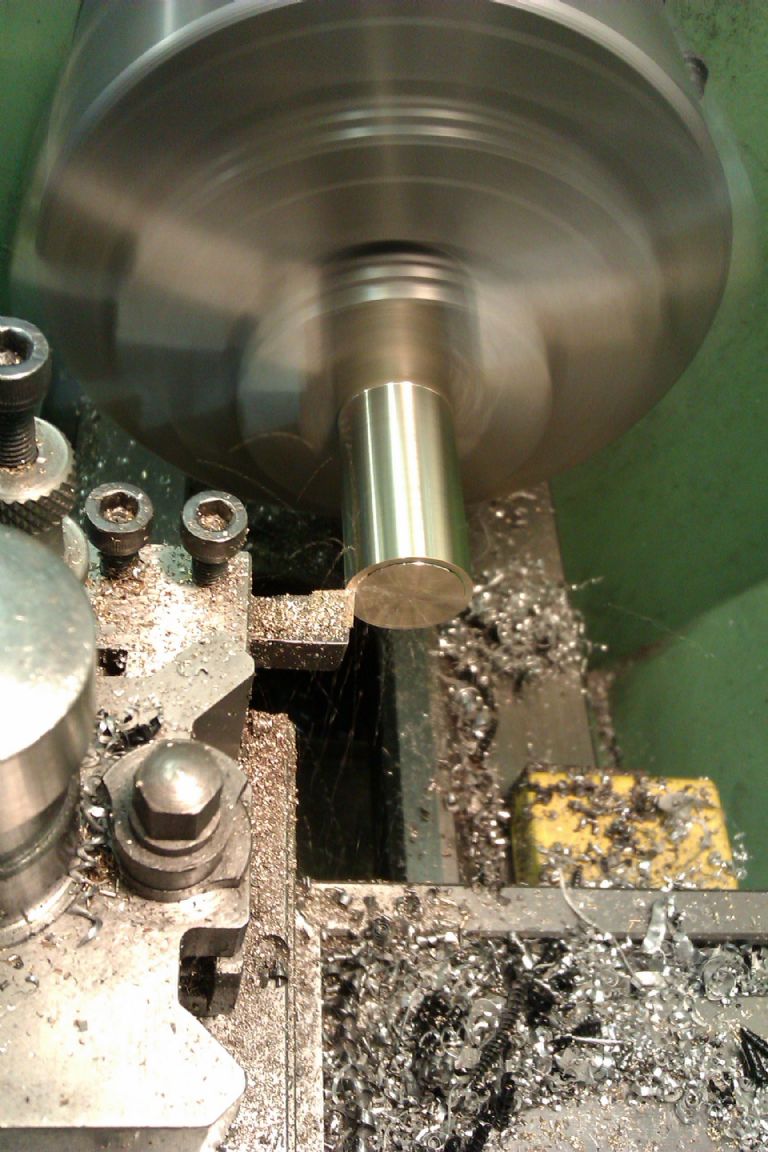

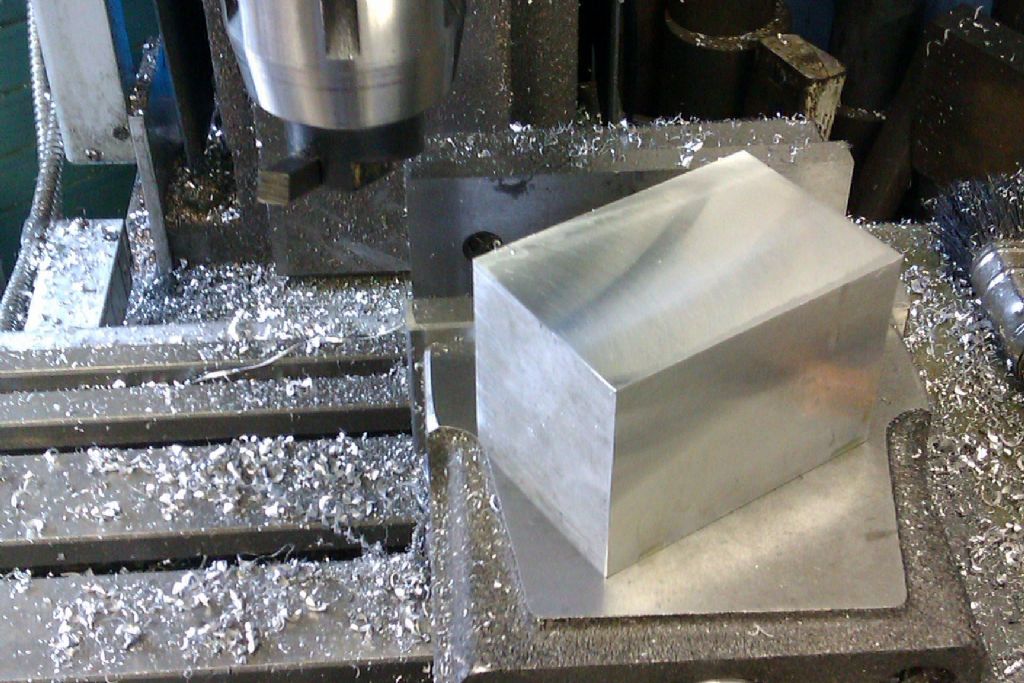

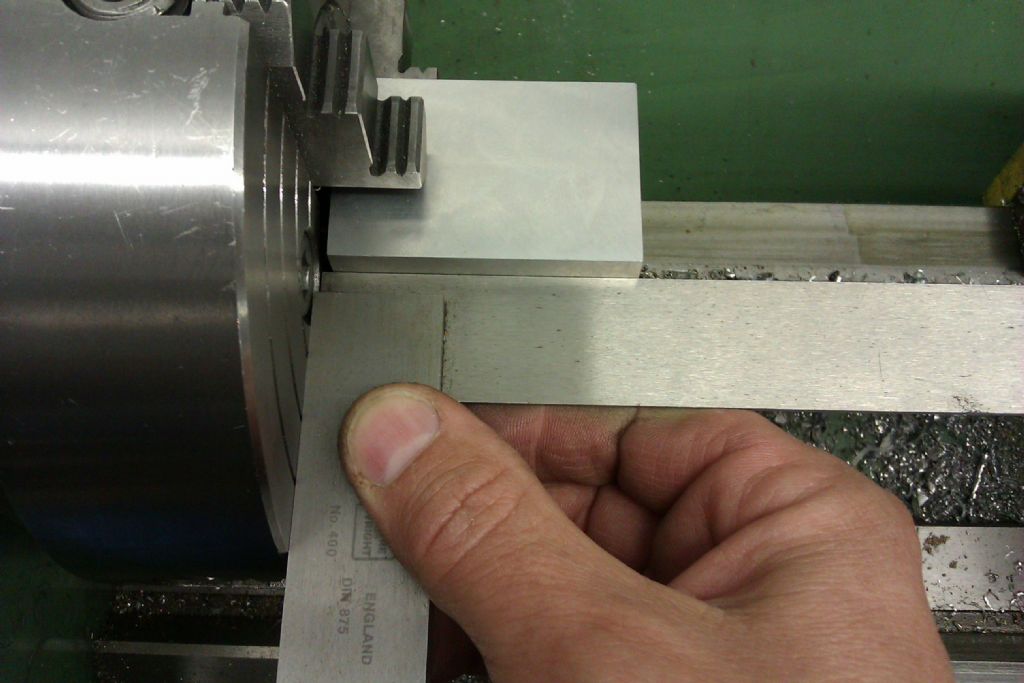

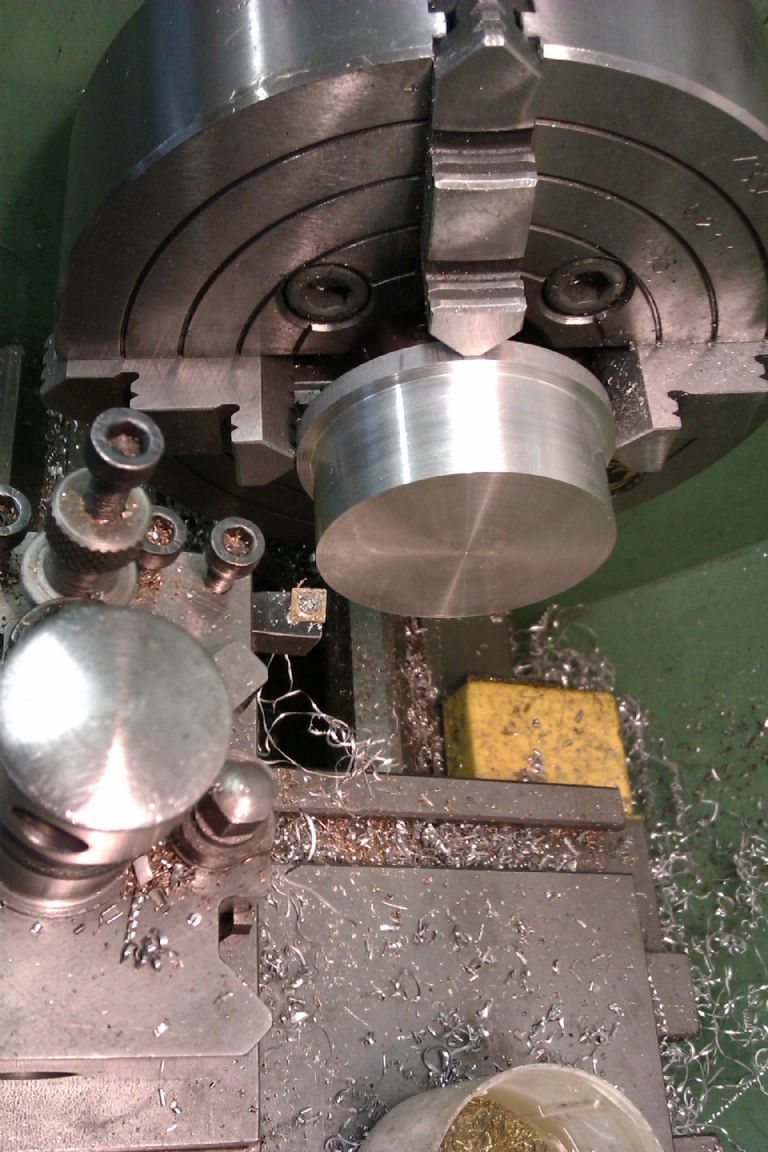

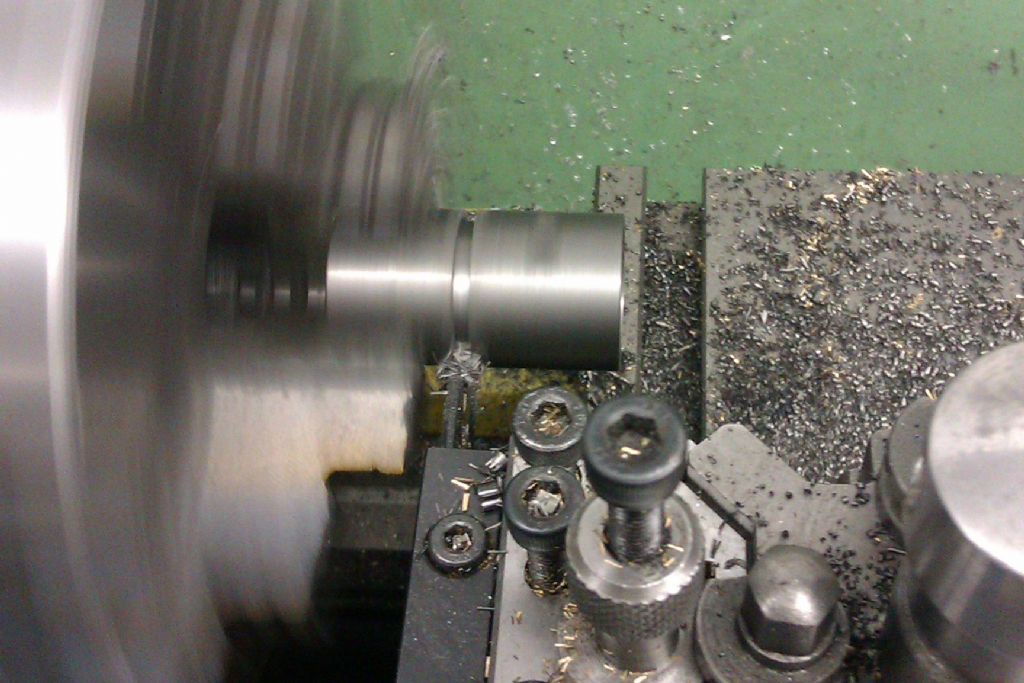

A length of 1 5/8" bar was chucked, faced, center drilled and then the outside skimmed to just remove enough metal to get a clean surface, this became my finished OD – 41.1mm slightly up on the drawings 40mm.

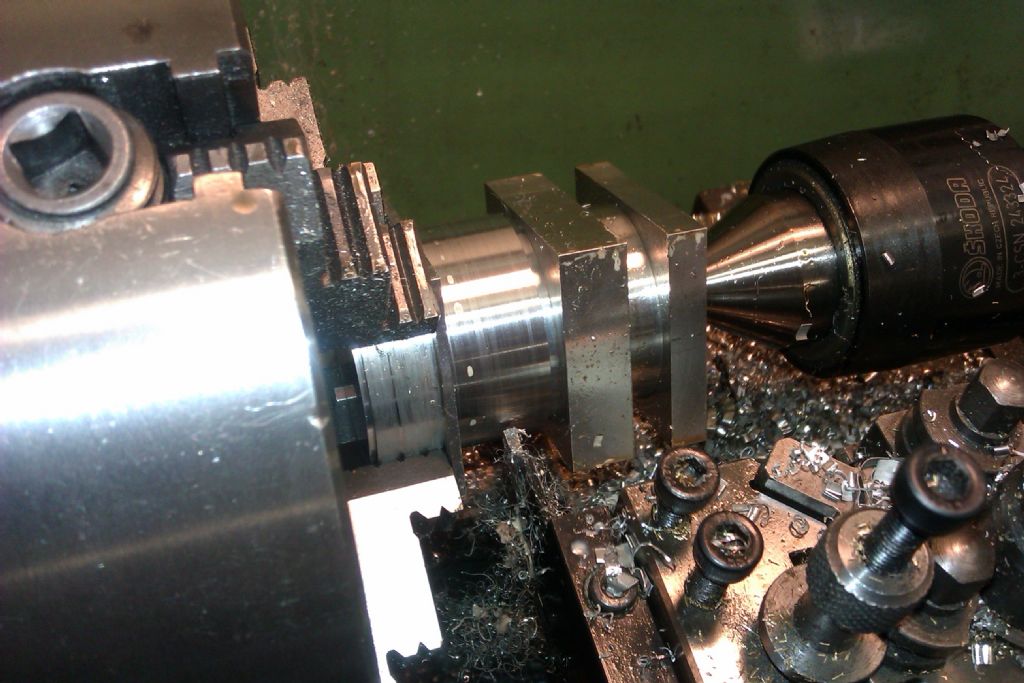

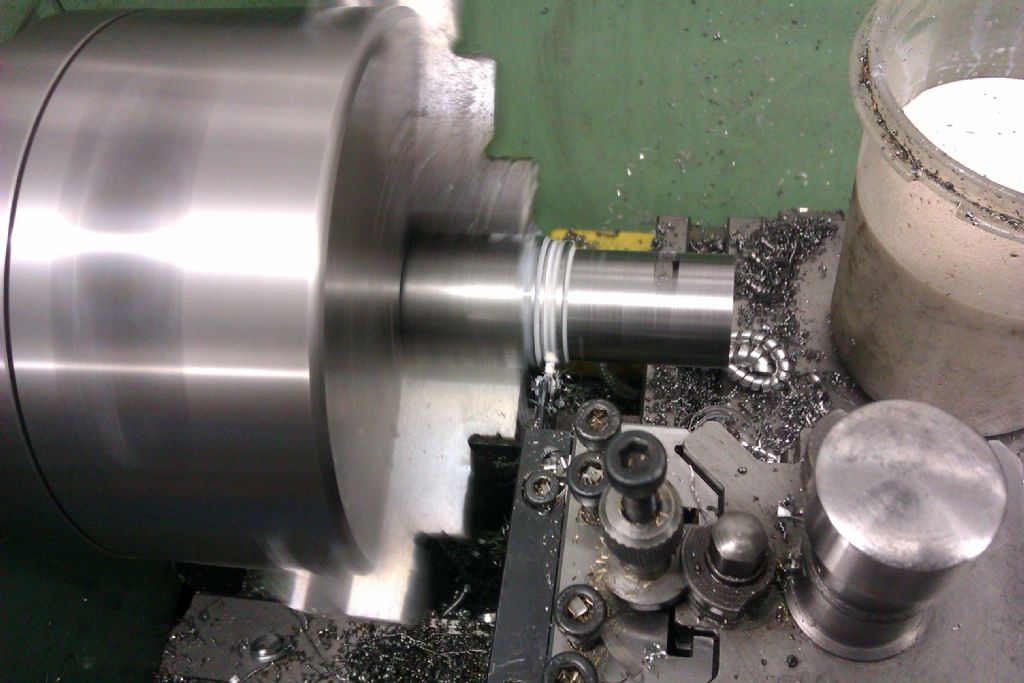

The spigot was machined to size and then the tailstock centre brought up to give support while the cooling fins/grooves were cut. I went for a different pattern of 0.050" fin, 0.050" groove, etc as this suited my 50thou parting tool and gave me room to get an extra groove. Due to the larger diameter I also increased groove depth from 1.8mm to 2.5mm

The edges of the fins were tidied up with a small cut from the usual chamfer tool.

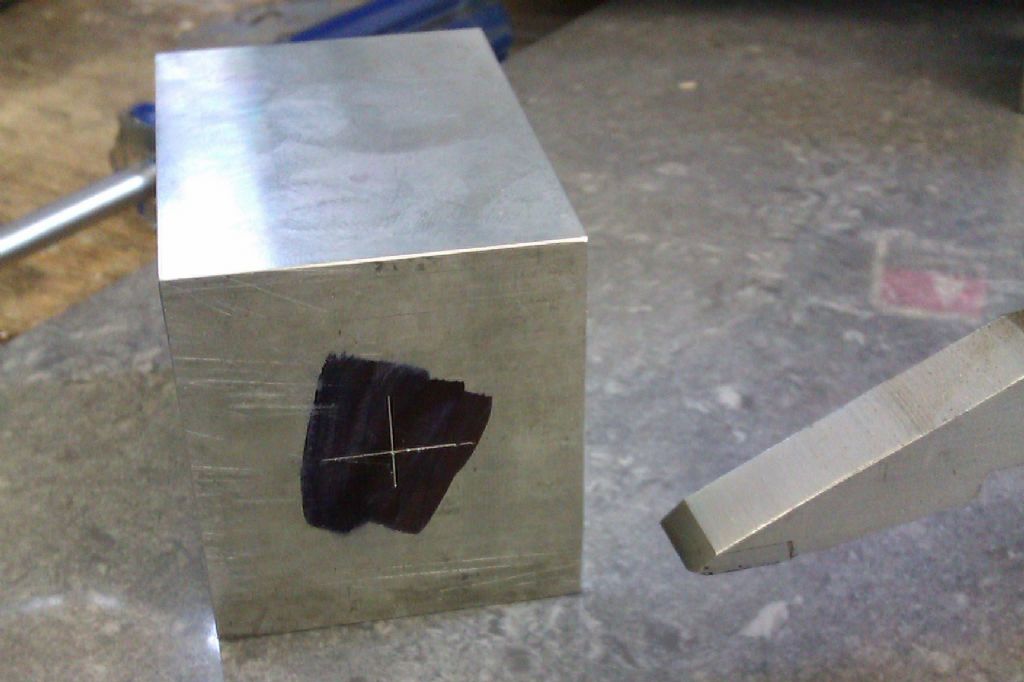

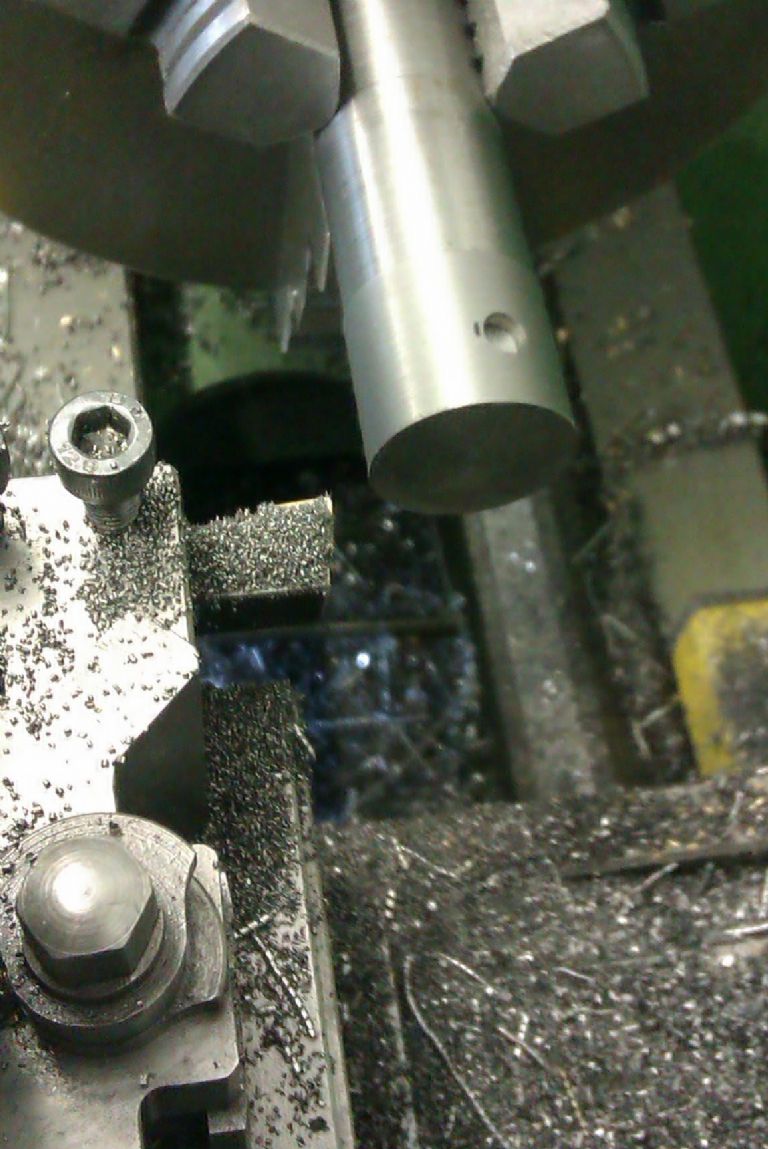

A form tool for the "hemi" head was ground up from a 3/8" HSS blank with plenty of clearance to stop it rubbing on the bottom of the cut, did not bother with any top rake and it gave a good chatter free cut over its whole width at about 250rpm.

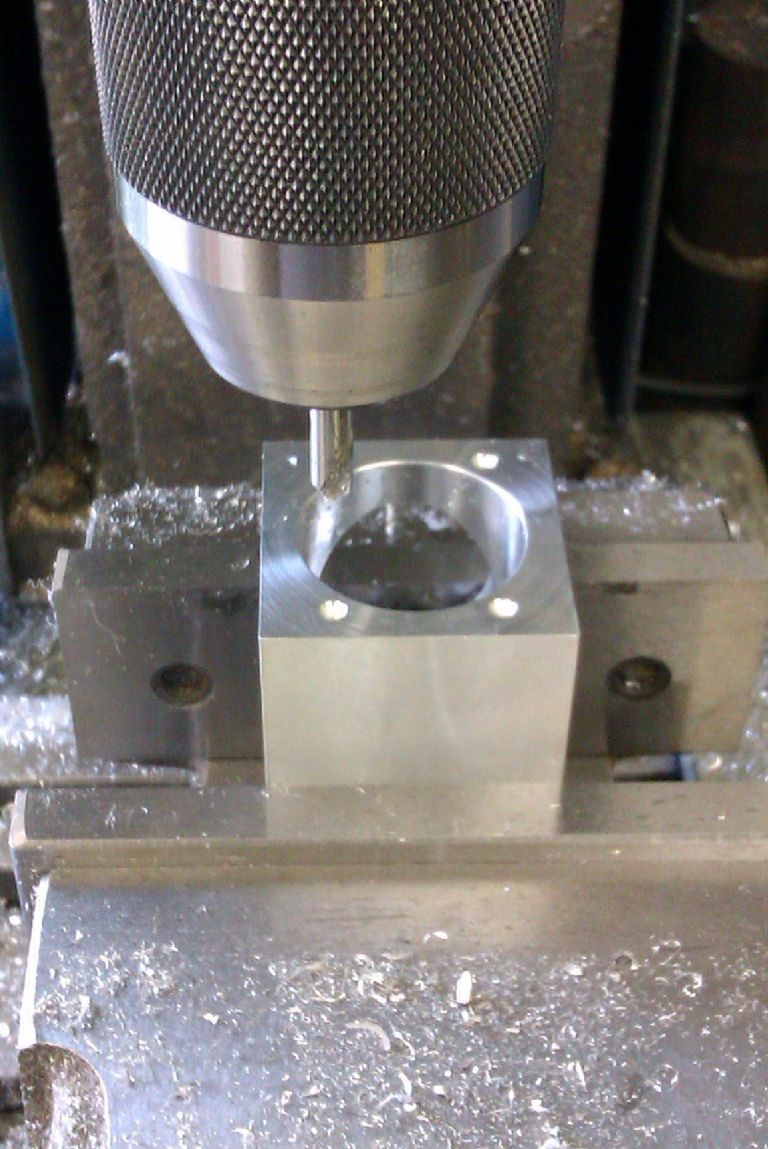

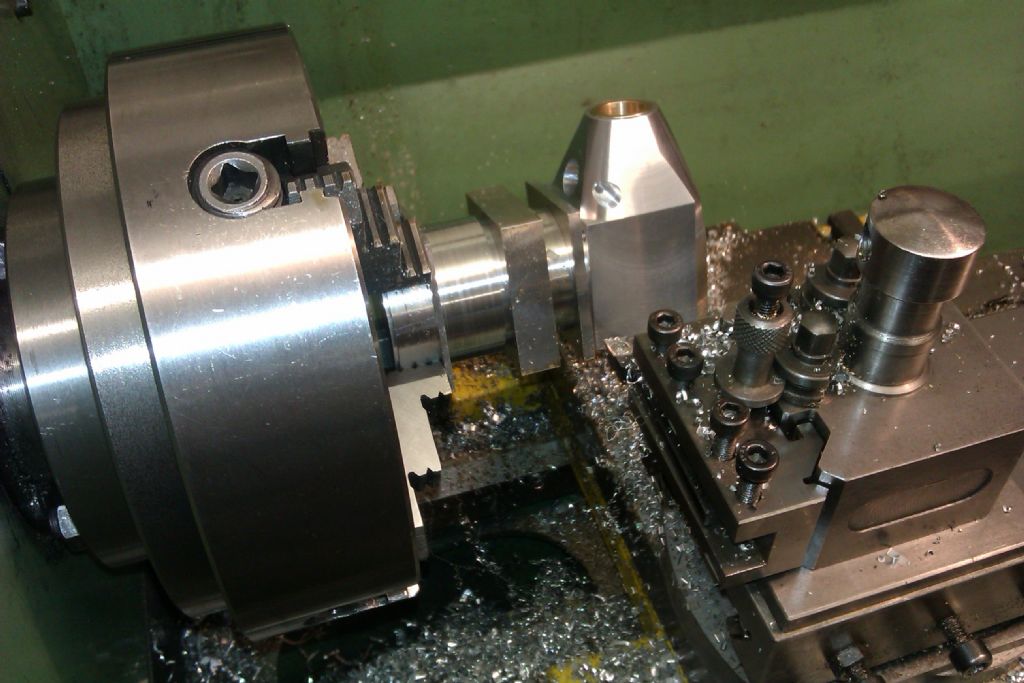

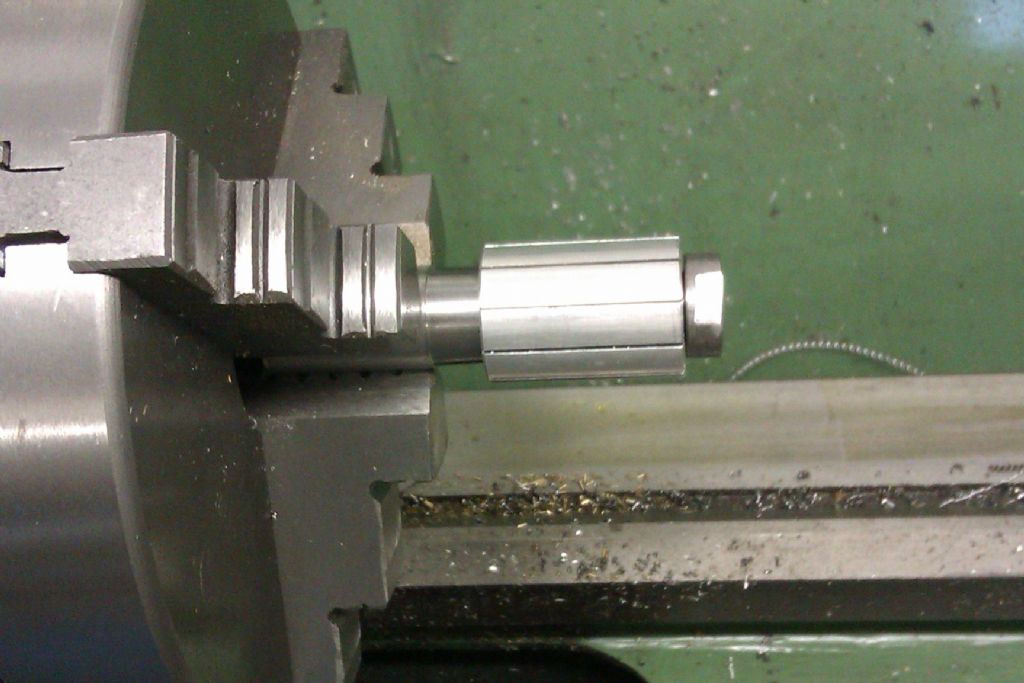

The head was then parted off over length, reversed in the chuck, faced, bored and the chamfer around the plug hole added with a small boring bar. I made the head 1mm taller than drawing.

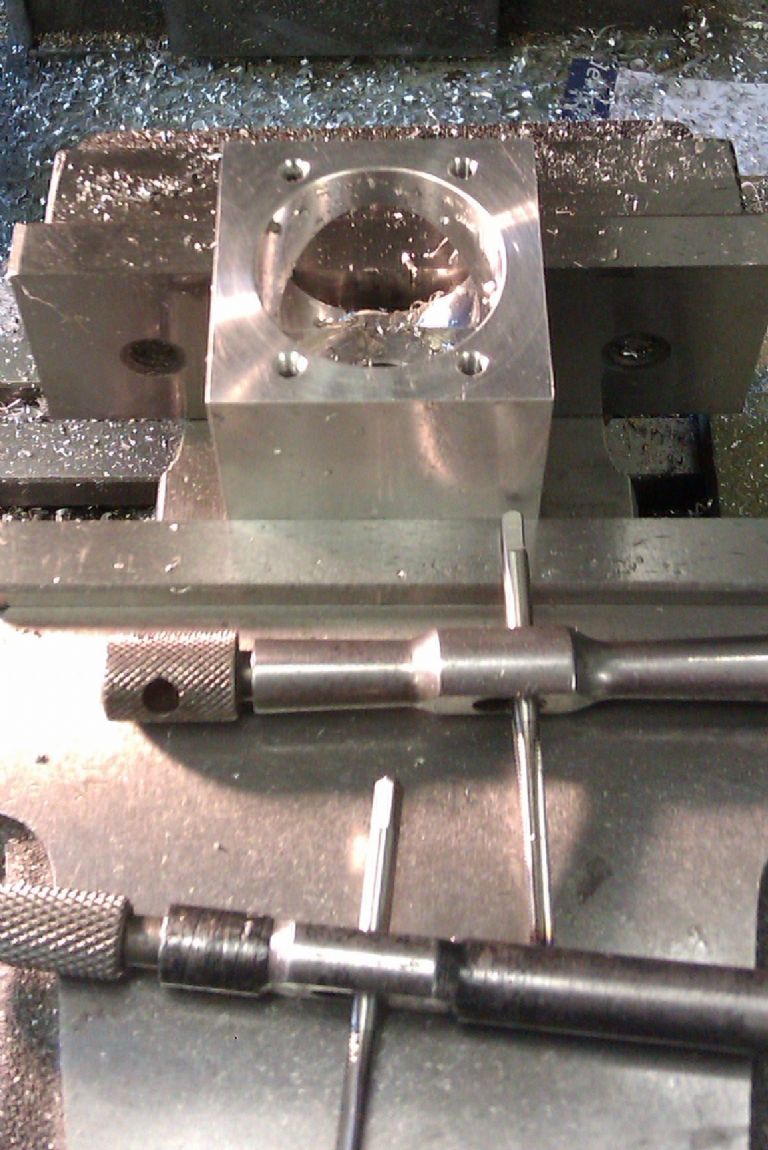

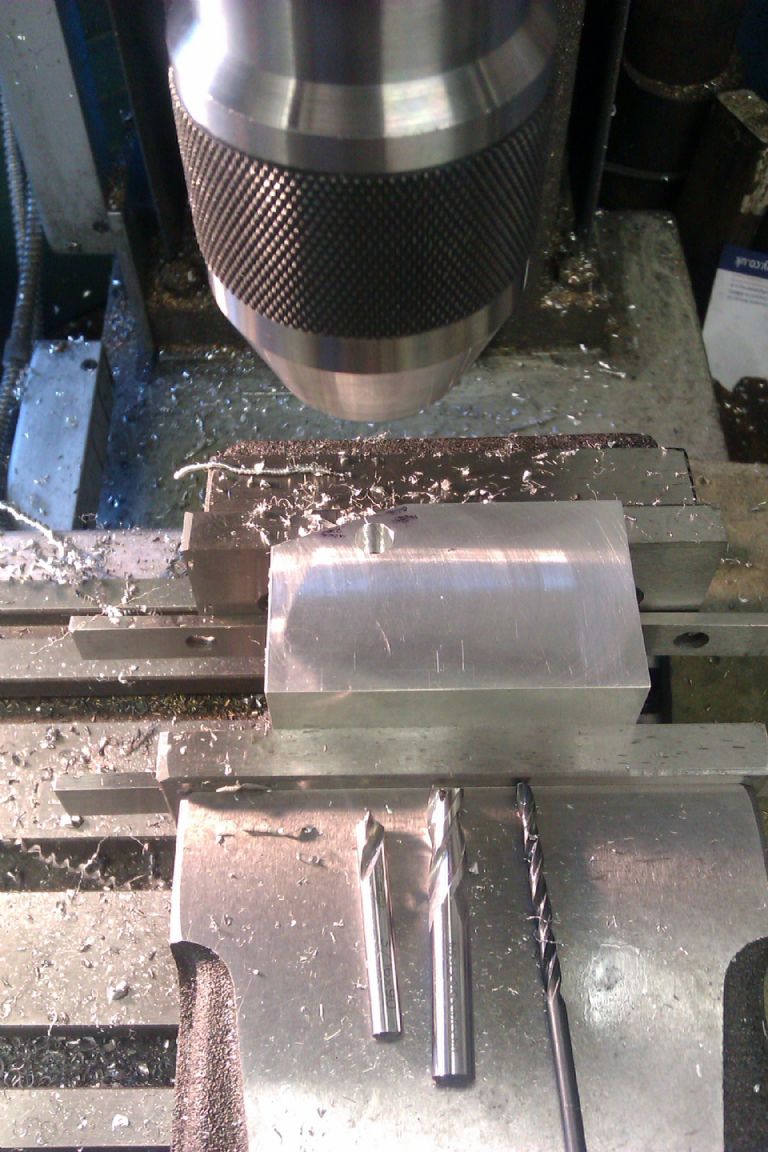

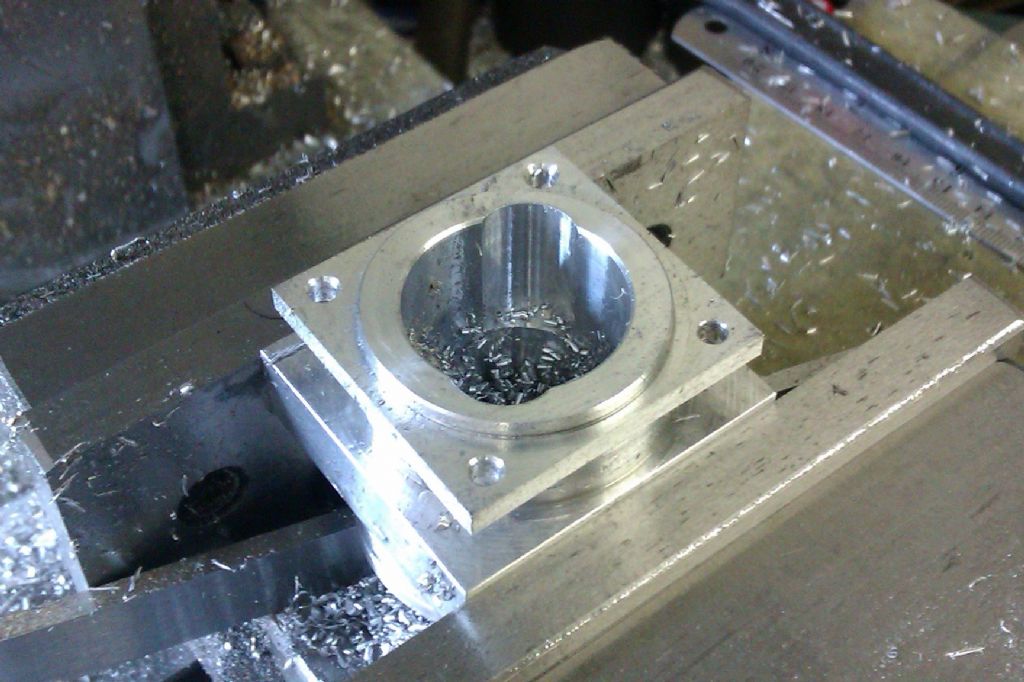

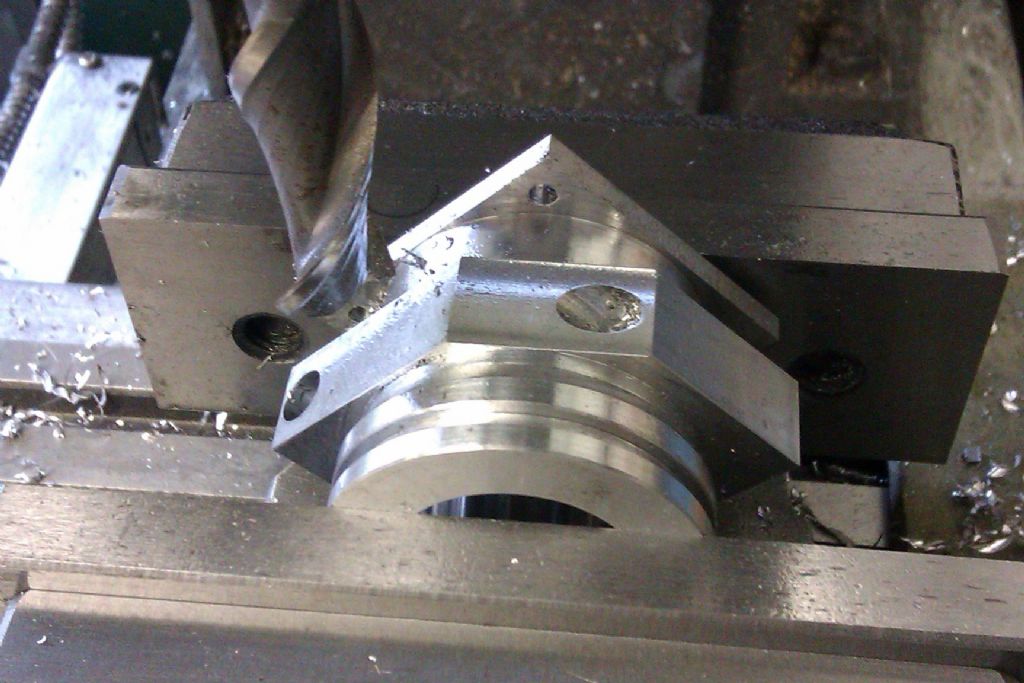

I picked up the centre of the plug recess in the mill and then set the four holes from there, drilled 3.1 (3.5mm on the drawings seemed a bit excessive clearance for M3) and counterbored with a FC-3 cutter followed by a quick touch with the CSK.

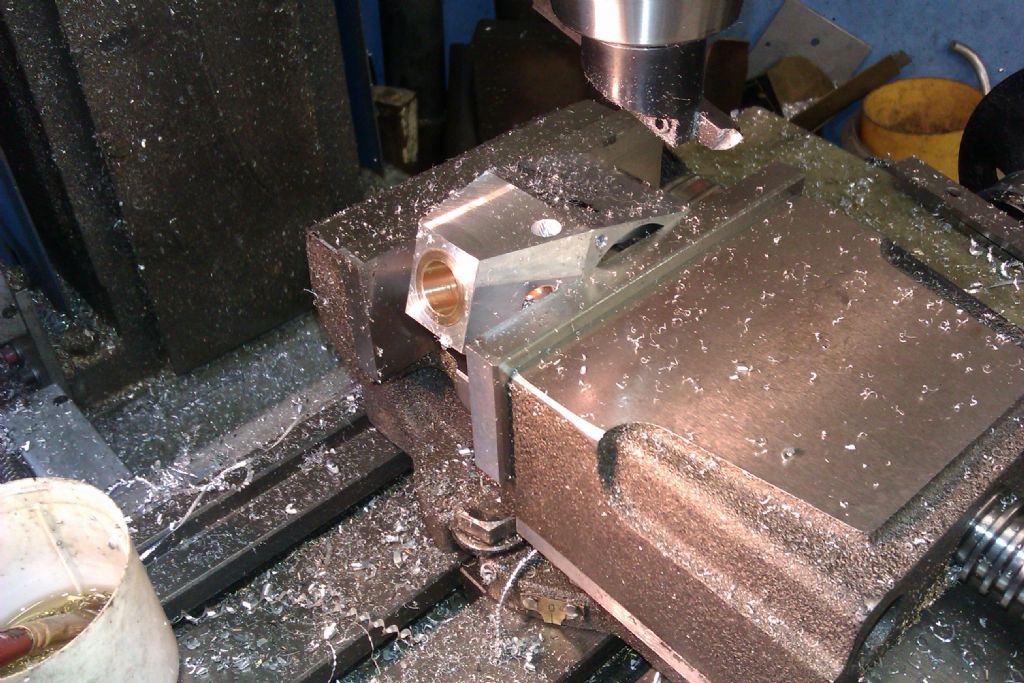

The reason for making the head that extra 1mm long was so I could have a bit of fun with a slitting saw. The head was set square in the rotary table chuck by using a tri-square against two drill bits pushed into the bolt holes and then the saw set to centre of the head. I worked out a suitable spacing and then took a series of 1/8" deep cuts across the head. Note the M5 nut in the plug hole, this is screwed to a rod that passes through the rotary table with a nut and washer on the other end to hold the head into the chuck, I was worried the saw may pull it out of the chuck as the spigot is quite short to grip.

After a bit of de-burring with a needle file this is what the finished head looks like

Cont'd

Edited By JasonB on 01/07/2012 20:14:41

Anders Be.