I can see this thread gets some views. I'm guessing mostly folk shaking their heads in dismay at quite how much trouble I can cause myself and how much of a mess I can make….

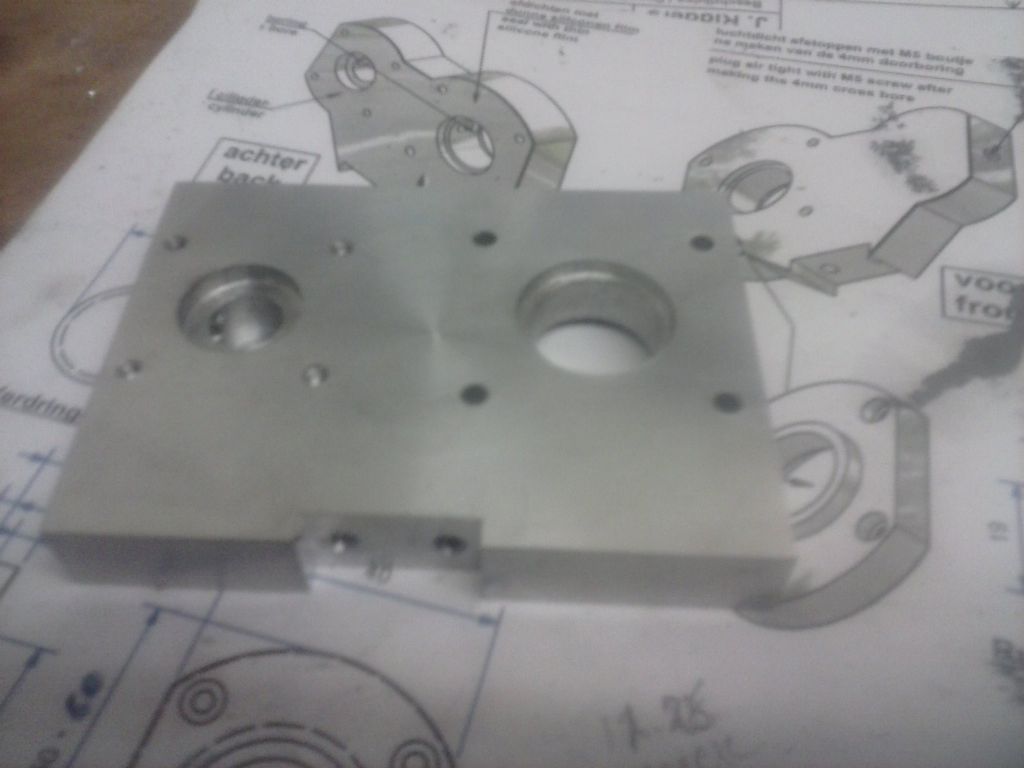

I spotted the other error on that last pic and made yet another blank up and actually got to the last pic stage without any more faux pas. it's been a long slow slog from there still.

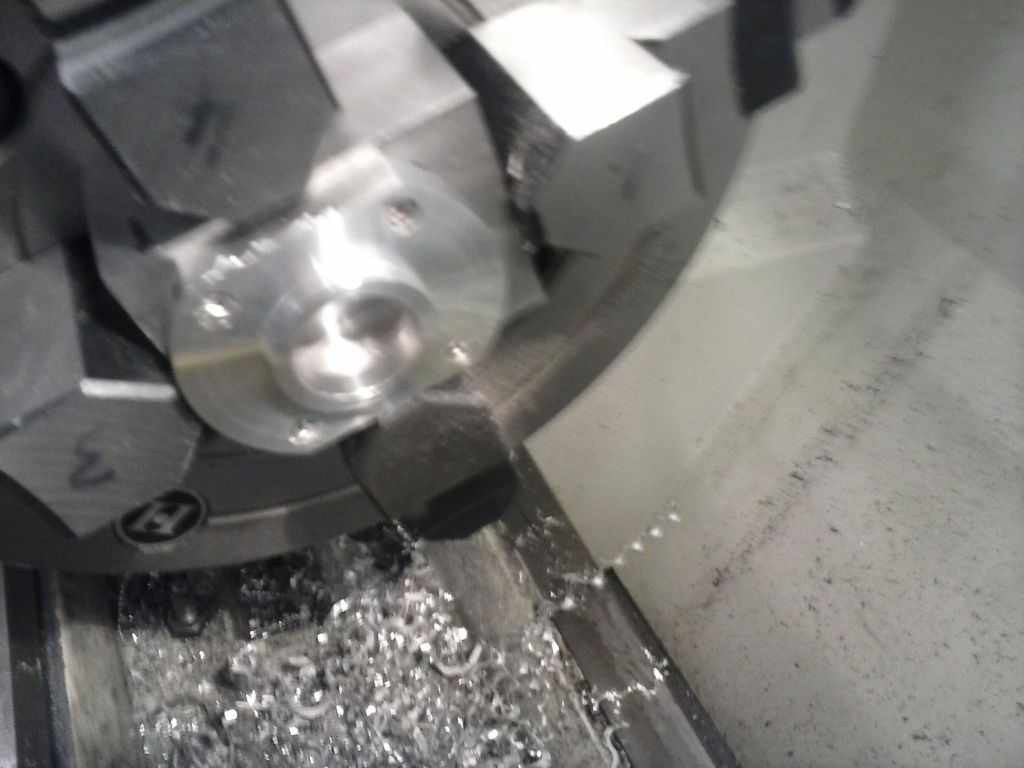

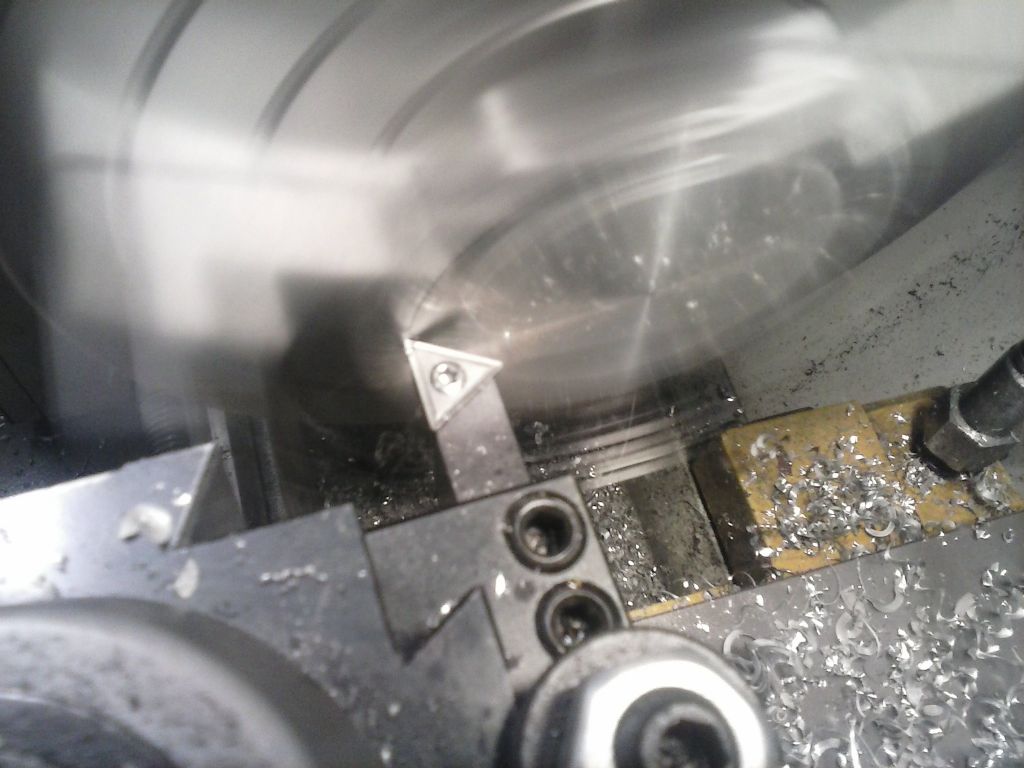

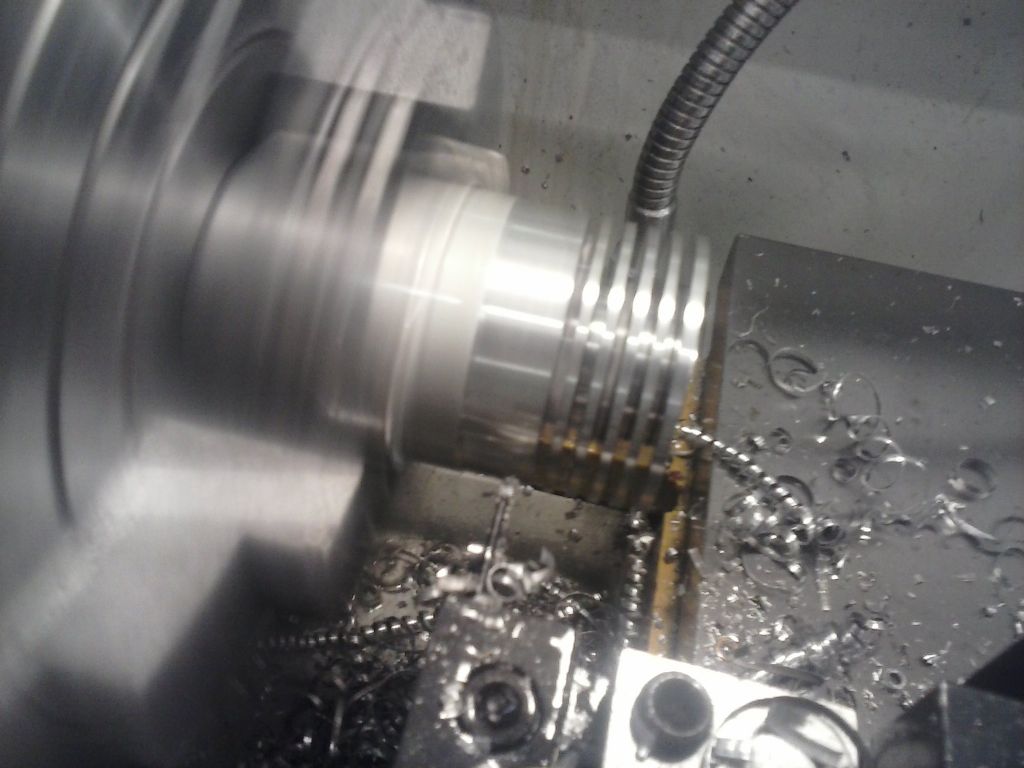

I cut and cleaned up the millscale and squared up some 12mm hot roll plate on the mill before drilling a 16mm hole in the middle and mounting it on an M16 bolt to turn the diameter in the lathe.

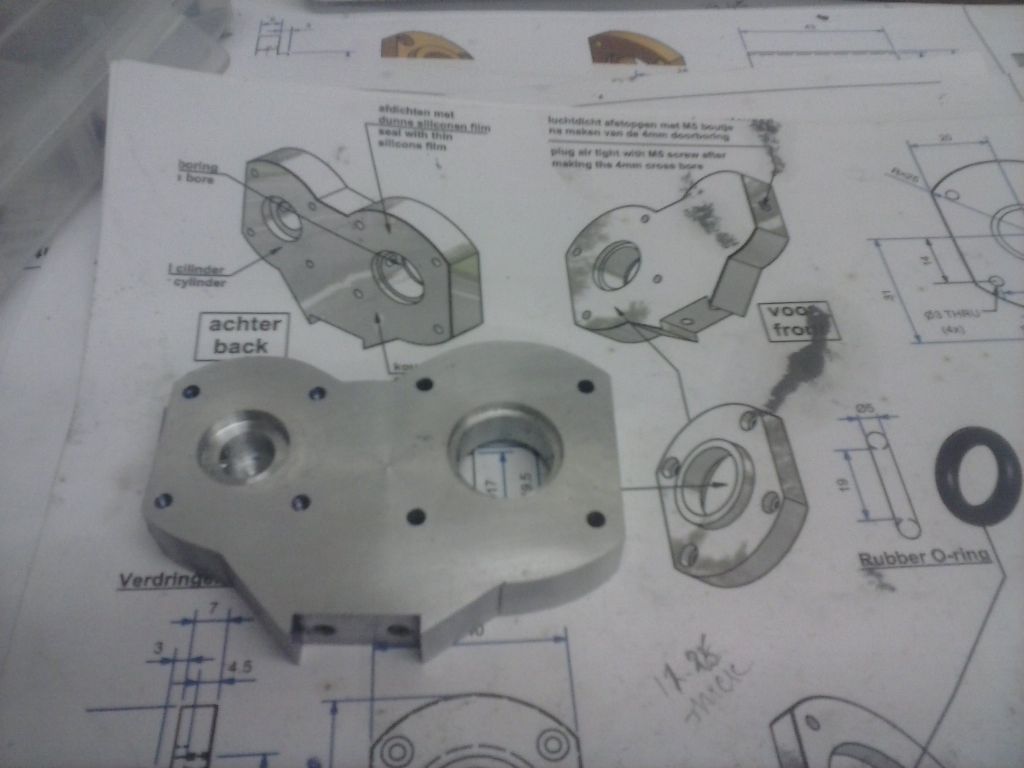

that wasn't so easy either. I'd stupidly expected that I'd be able to knock the corners of easily enough and easier than converting my bandsaw to vertical use (the clamp on it wouldn't hold a small piece like this for cutting off corners). Since It was going to be held by the m16 threads I decided a collet would be the best holder in the lathe. But the crusader lather short taper and the rattling of cutter on corners just kept loosening stuff. So it ended up in the 3-jaw.

It was still a slog using an HSS lathe tool to knock this roughly round then finishing with an indexable tool and slow feed to final size.

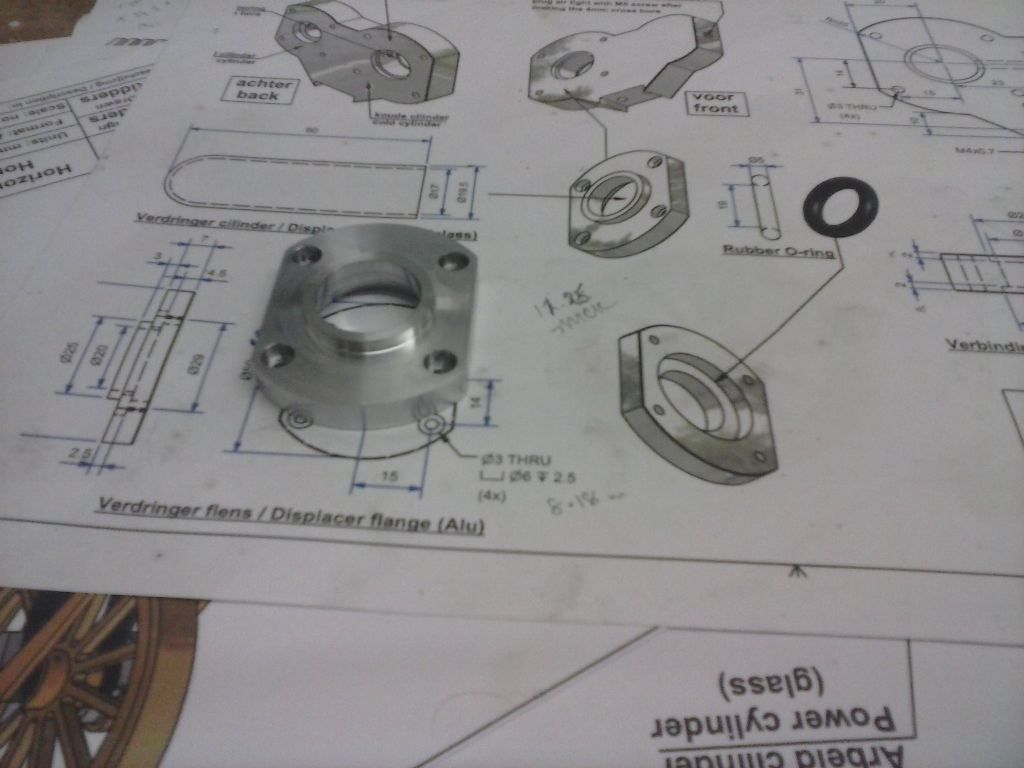

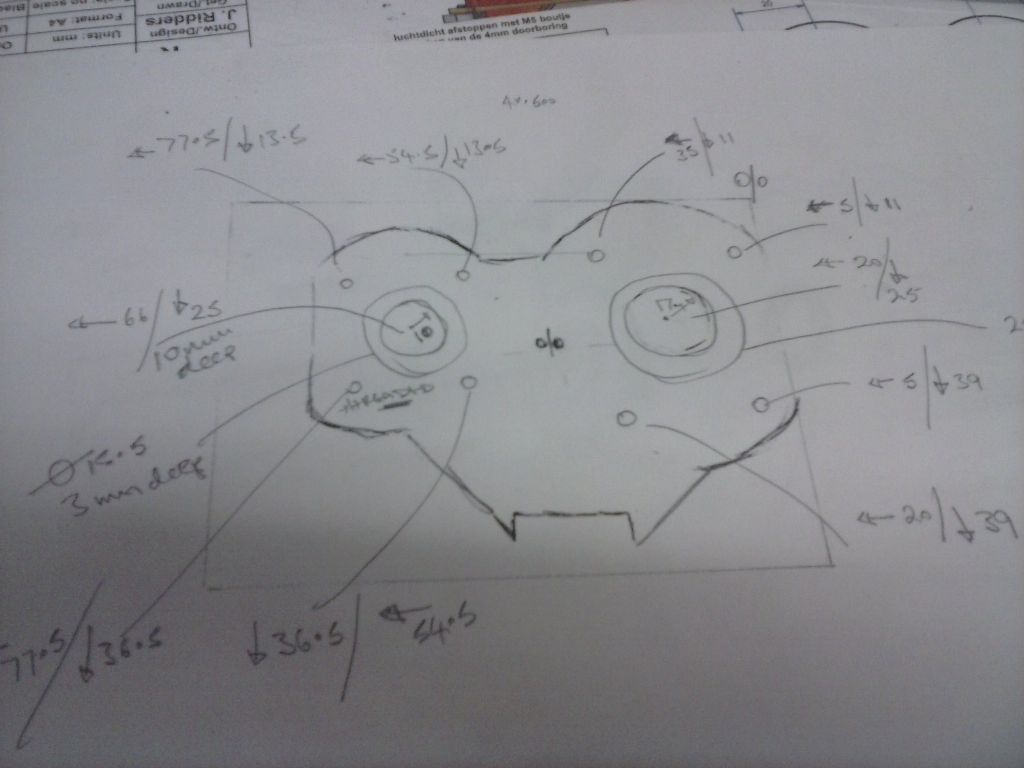

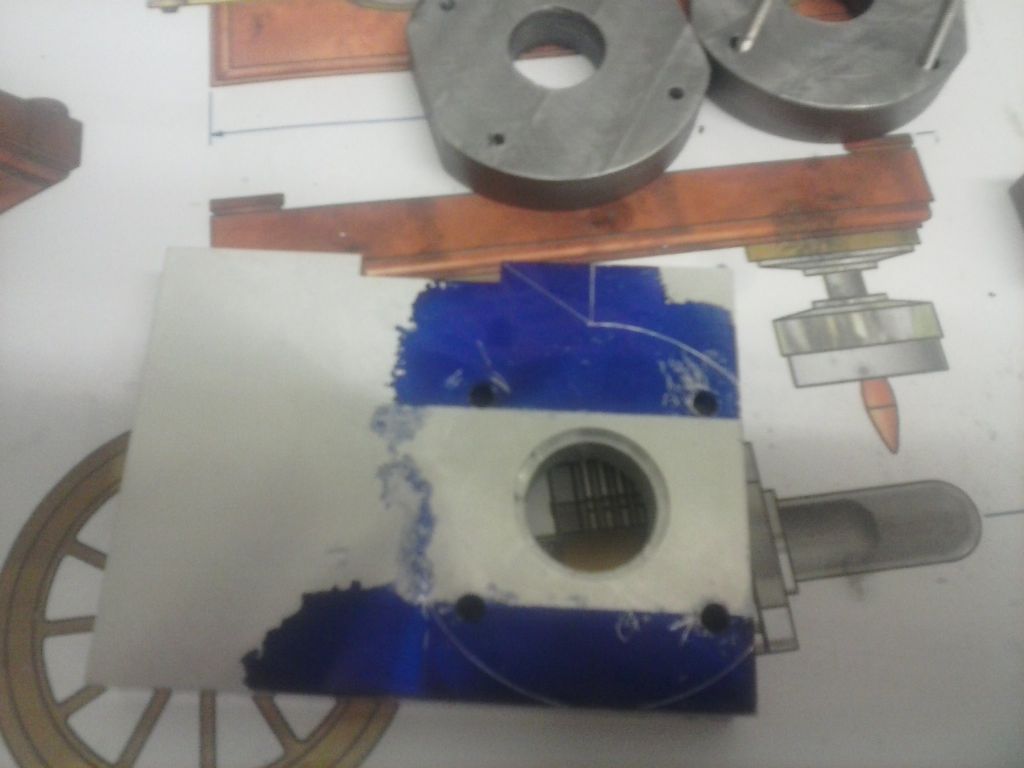

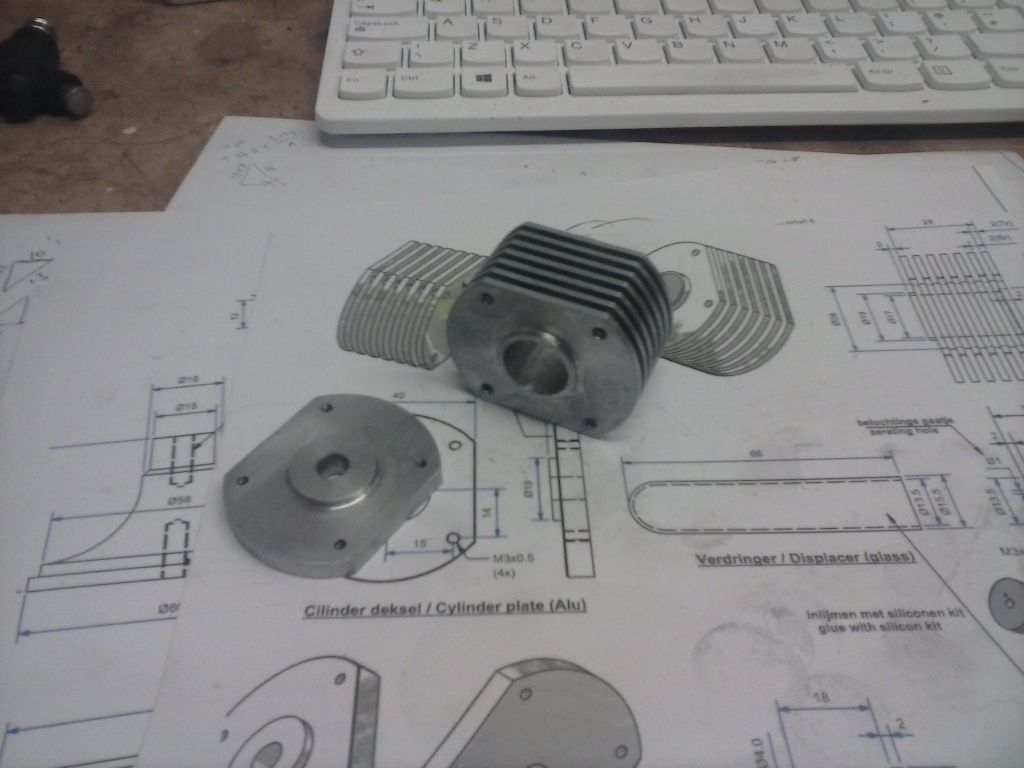

Then it was over to the mill to pop a couple of flats on the circles and drill for bolts through that main holder part which I blued and marked up.

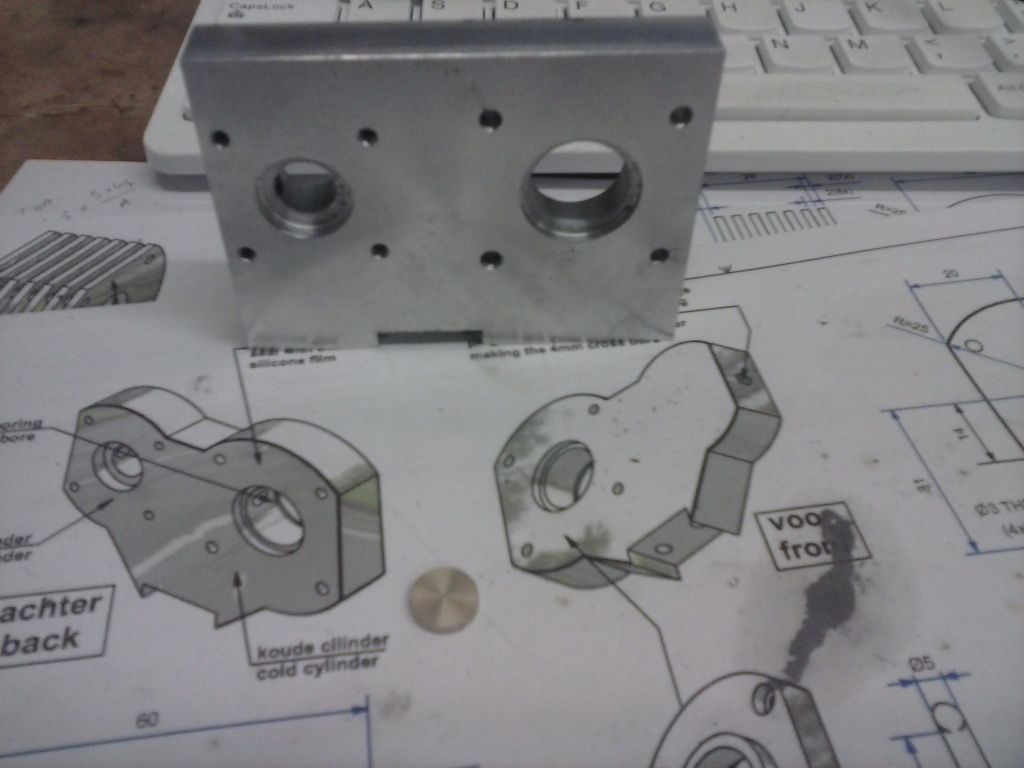

It then got roughed on the mill and finished by hand filing with those discs as guides. I'm a filing tyro and not good at it.. took me a lot of patience since I really didn't want to start again (yet again)

Actually not bad but while you can't see it here I proved to myself yet again that i need a z axis DRO.. the handwheel marks just aren't consistent (and yet i allowed for backlash etc). The two flats are not identical even with touch-offs and care to the same cut depth each side.

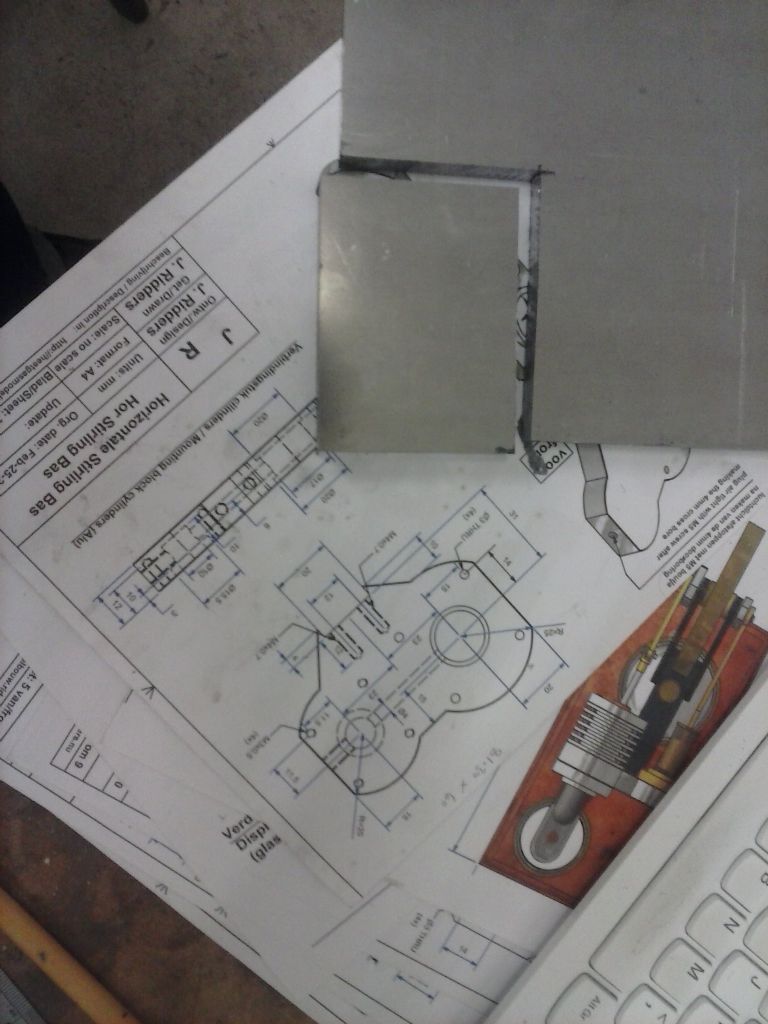

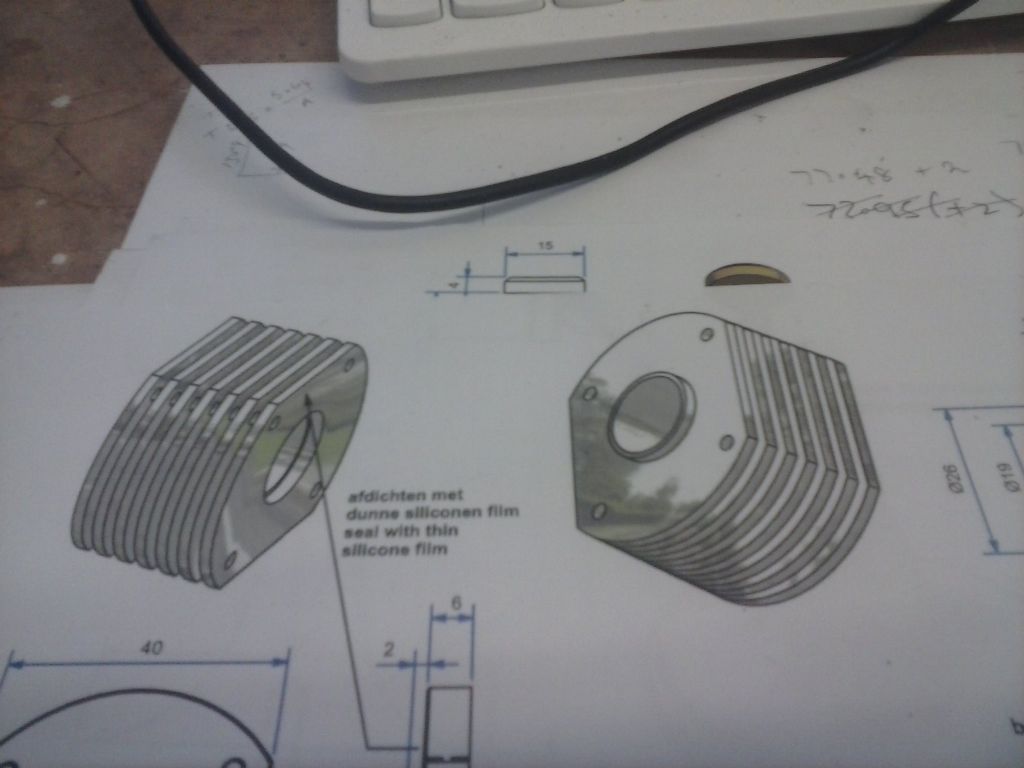

I had intended to cut the discs down for the second part but decided to keep them for possible mods on this first side if i have to file a little smaller.

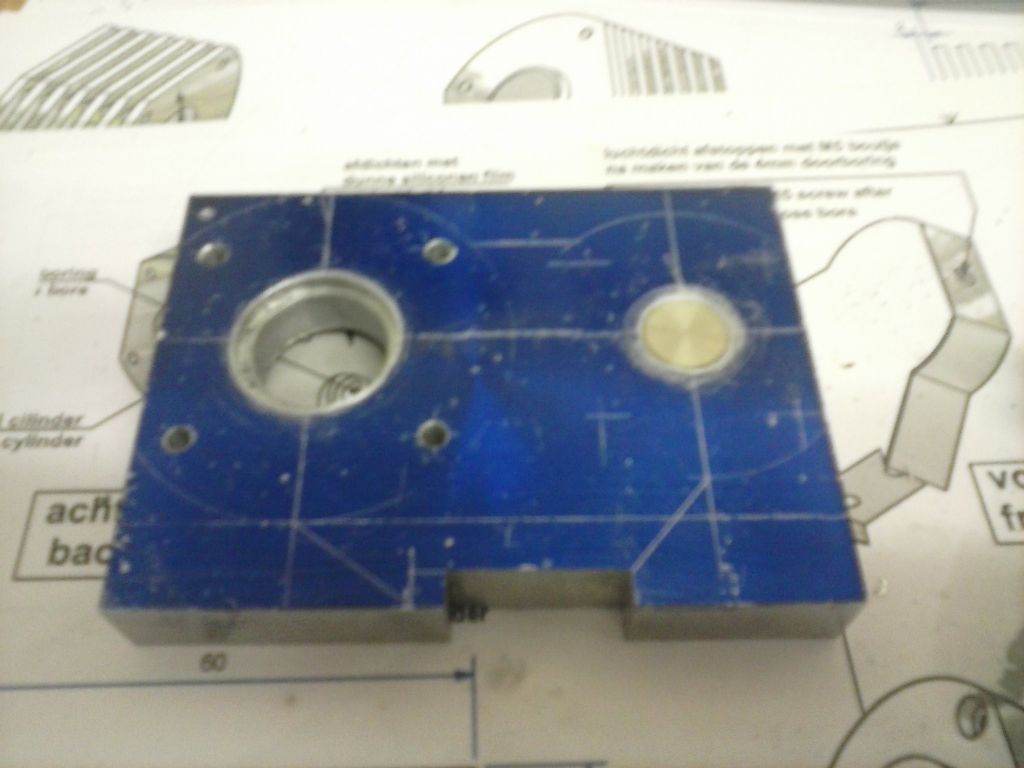

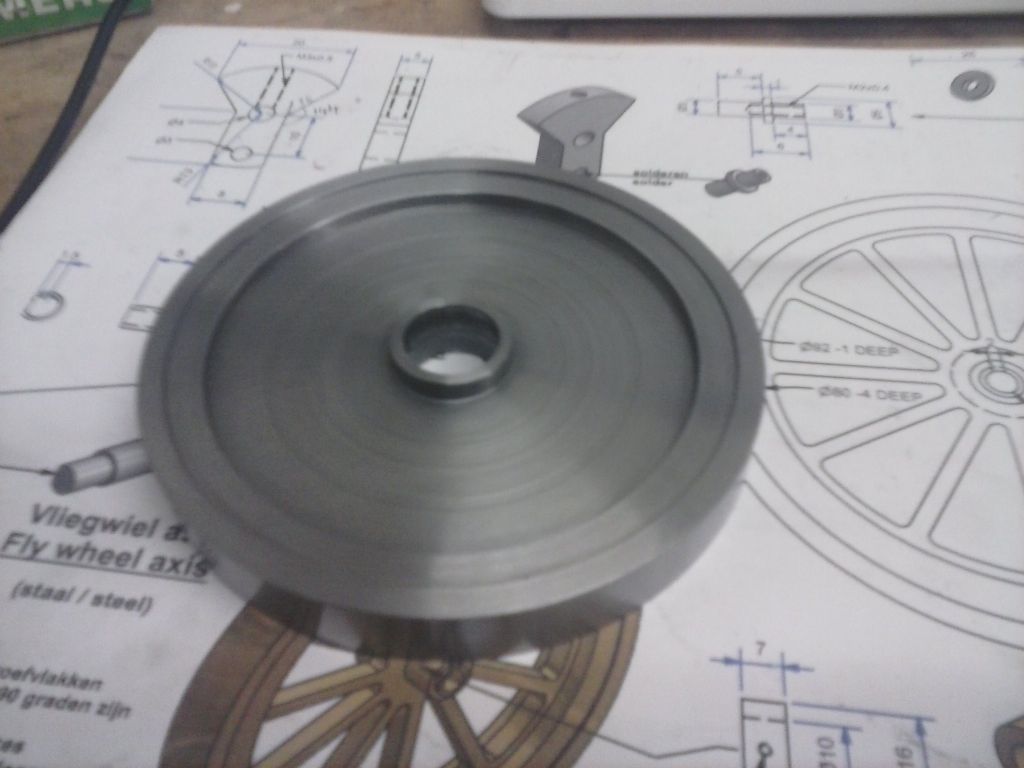

So a second disc was made up.. much thicker since this would only be one-sided on the part and i know how easily my filing can wander off the horizontal.

I also decided not to put flats on which made finding the center on the mill interesting – it's a bit tight in there.

So the part was blued again for this side and with the disc mounted then once again marked out and milled roughly before filing.

I really do hope i don't have to make another one of these – there's a lot of hours in it.

Ian S C.