Hi Dave,

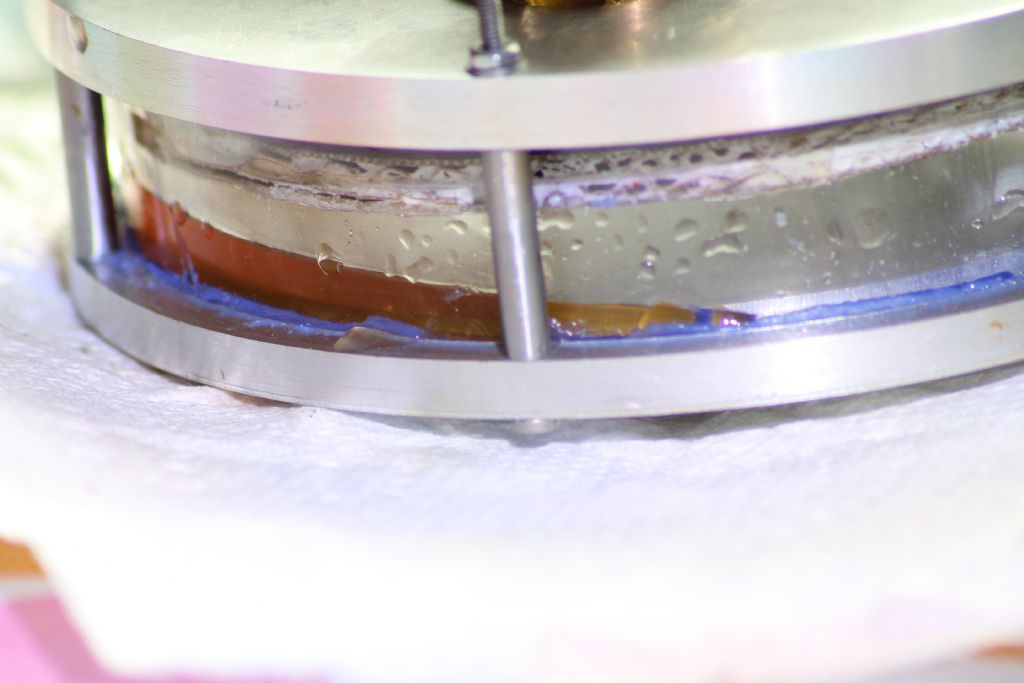

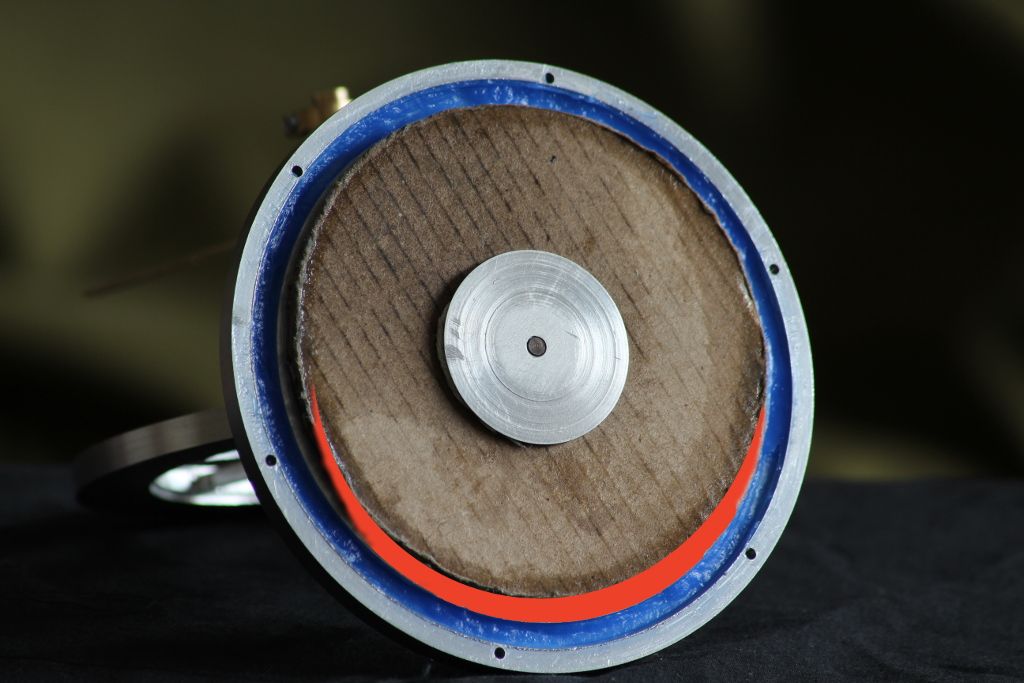

I am by no means an expert, but I have made one of these and it runs. I used available materials for mine, so I have a steel piston, silicone sealant on the top and bottom plates, and the spacers are made stainless, as I didn't have any plastic available. So those factors shouldn't stop it running.

I think your problem is the displacer.

As you have made the displacer piston thinner have you made corresponding adjustments to the length of the piston rod and or the connecting rod to bring the top face of the displacer piston as close as possible to the under side of the top plate at tdc.

Have you made the displacer cylinder length such that the displacer piston almost touches the bottom plate at bdc.

If you have too much dead space, then I think this would stop the engine running.

Other factors that will stop it running:

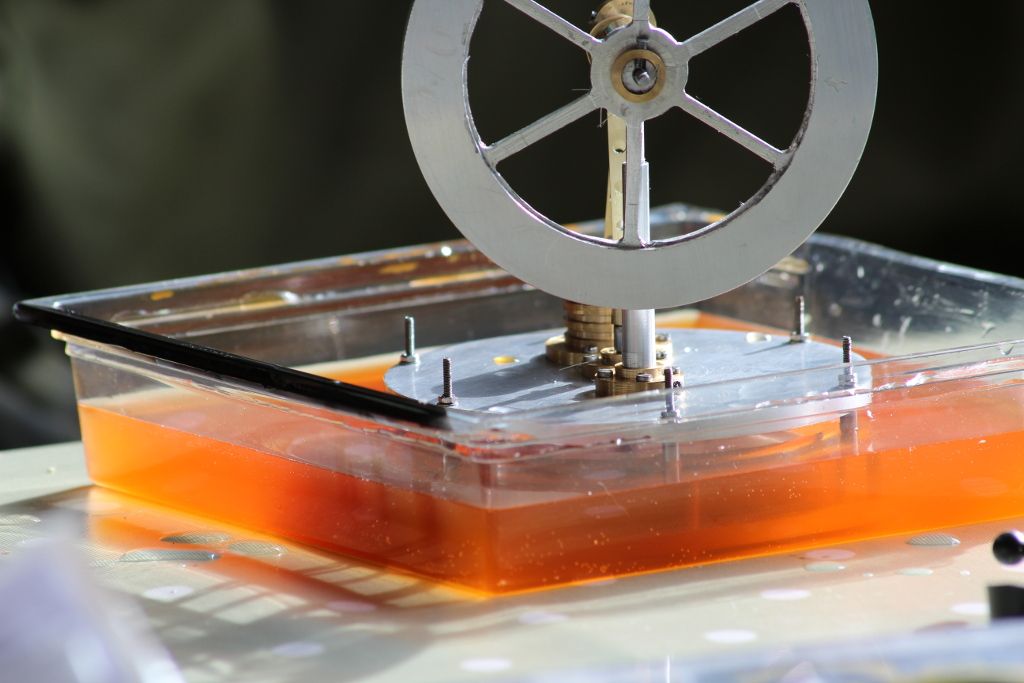

Air leaks, I tested mine by removing the power piston and sitting the engine in water covering just over the top plate. I sealed a bit of tube into the power cylinder with blu tak and blew down it, any leak is obvious from the bubbles. you don't need much of a leak to stop it working.

It helps if you achieve reasonable balance, I took the bottom plate off, then give it a spin, a bit of blu tak will do to get it fairly close.

Obviously the whole thing needs to be as free running as possible, but it seems like yours is ok, also the power piston needs to be a good fit, but it sounds as if you are happy that yours is ok.

If it were mine I would:

Take the displacer cylinder apart and check how close the diplacer comes to the top plate.

Put the tube on and check how close the underside of the diplacer comes to the bottom plate, obviously making allowance for the groove in the bottom plate.

These measurements need to be pretty small, probably 1mm or less. If not before doing any re engineering, get some better material for the displacer piston, either polystyrene or balsa.

If it is any consolation I was talking to Martin Gregory on the SMEE stand at ME exhibition, and when I told him I'd built one of these Jan Ridders engines and it ran, his comment was that i was the only person he'd come across that had made one work. Apparantly the proportions are not quite right, but I can't quite remember what is wrong. Martins own engine will run on the heat from your hand, the one I made from the Jan Ridders design needs a good cup of boiling water to work. But that aside it definately can be made to work. No disrespect mean to Jan Ridders he has done some great work designing engines and giving them away free.

Hope this helps

Good luck

Trevor

Ian S C.

I'd suggest one with a low pitch.

I'd suggest one with a low pitch.