Posted by coggy on 09/08/2019 10:21:21:

….

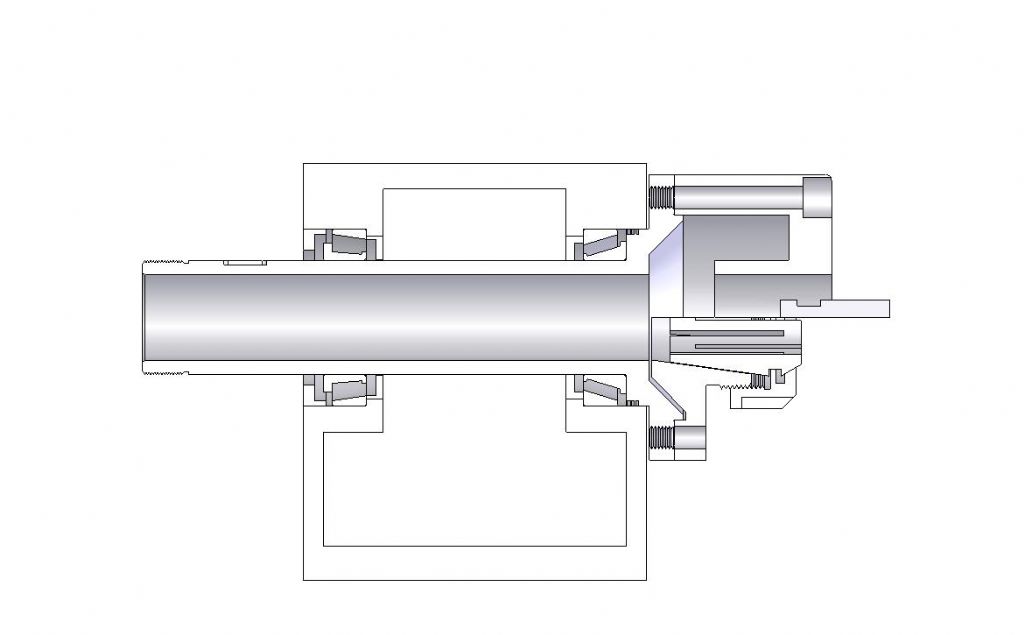

Plus is the 38mm bore lathe offered at the expense of there being less material around the bore on the pulleys, cogs etc. that the bore passes through. As most of these lathes seem to be only available once imported actually getting to see and compare 26mm and 38mm bore lathes is hard.

Has anyone ever compared the internals of these lathes with the different bore sizes. Is a 38mm weaker than a 26mm ?

I would suggest that the extra price hike is due to the extra mass of metal required around the bore on the pulleys, cogs, etc. Every machining operation will entail more surface to be machined and machining costs are part of the product cost.

While a 50% increase in area machined, the volume of material being removed from solid items is over twice the amount for a 38mm hole over a 26mm one.. It all costs extra money as well as larger castings in the first place.

I would not expect either size to be weaker than necessary – if they are designed properly. Smaller, within reason, is always going to be cheaper. That applies to bearings, too. Then there may be larger gears required – more teeth for the same ratios? The price does not come down as the size increases.

Only when normal sized items are miniaturised, do prices start to rise again in the opposite direction, but now due to design problems and higher precision.

One might expect that a lathe designed around a 26mm hole might be about the optimum size for minimum production costs, but maybe 16mm would be cheaper – myfords and drummonds were cheap in their day, so perhaps they were right and the 26mm ‘standard’ has been adopted for reasons other than lowest cost?

thaiguzzi.

![wp_20190418_004[1].jpg wp_20190418_004[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/829240.jpg)