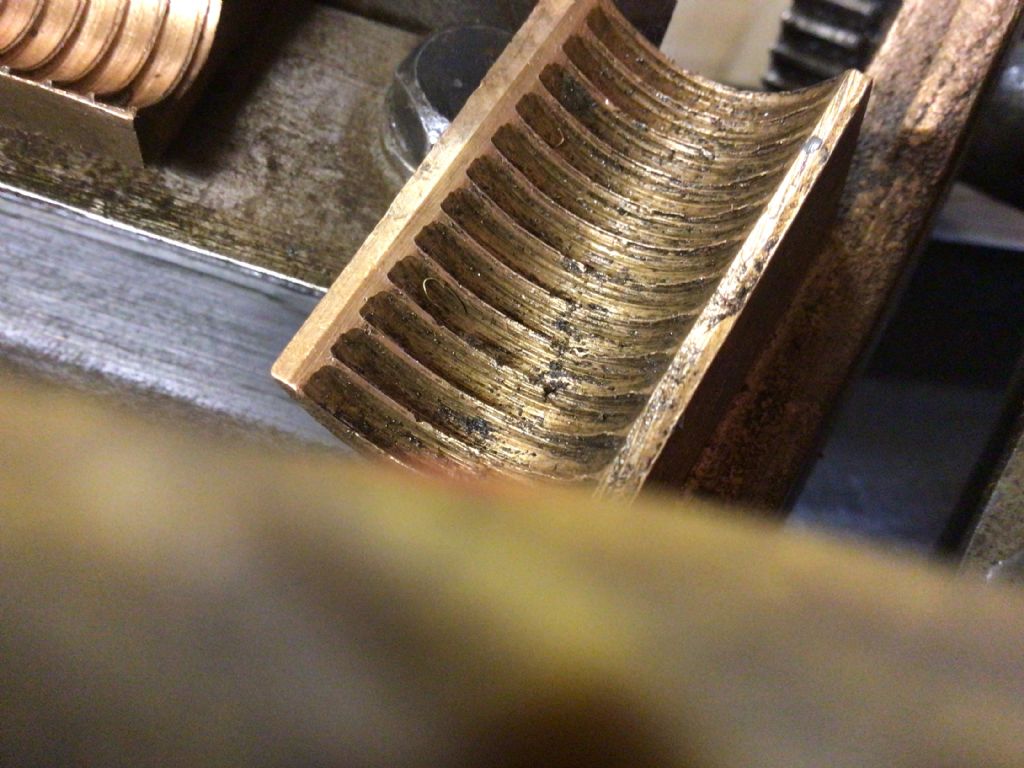

The technical term is basically "well knackered".

As you aren't equipped to screwcut a new one and finding a decent used replacement is likely to be challenging an unorthodox repair will be needed.

Hot moulding two half circle bored pieces of delrin around an unworn part of the leadscrew is known to work well. The difficult bit generally being attaching the new delrin halfnuts to the mechanism. There are several write-ups of the technique on the internet. Most workers elect to bore out the halfnut casting and arrange flanges on the delrin half cylinders to keep them in place under screwcutting loads. Adhesive, pins or teeny screws being enough for retention when not in use.

In your position I'd be inclined to try a modern metal loaded filler. Put a couple of small holes through the thread remains to help the excess filler squidge out, coat the chosen part of the leadscrew with a release agent and squeeze the two half nuts together around the screw to form a thread. Soot was a common release agent when babbit bearings were poured, I imagine silicone spray, PTFE loaded lubricant spray or one of the thinner, retentive oils would also work. Hardest part is going to be making sure that both halves of the nut align. May have to be done on with the apron partially assembled leaving little room to work.

But many machines eg Colchester, Kerry et al get on just fine with only one side of a half nut. So doing only one side might well suffice. I imagine you have no plans for vast amounts of screwcutting so even an, objectively, insufficiently strong repair might last for several years.

Some experimentation on disposable things is usually advisable before committing to a unorthodox repair on hard to replace parts.

Clive

Lee Rogers.

. I think I could with the correct width of cutting disc deepen the thread a little…..of course I could end up with a nackered half nut……

. I think I could with the correct width of cutting disc deepen the thread a little…..of course I could end up with a nackered half nut……