… continued

My back-step is in regards to velocity ratio. I had become rather tired of attending to all the manual (CAD) iterations and abandoned the exercise when I got around to messing with lantern pinions.

In that case, I retained the number of teeth, the lantern pinion having 8 (eight) pins (leaves) meshing with the John Wilding’s 290 tooth large wheel. The teeth of the latter being of conventionally accepted cycloidal design.

Consequently, I can only show what was happening where Mr Wilding’s pinion was cycloidal not a round pin.

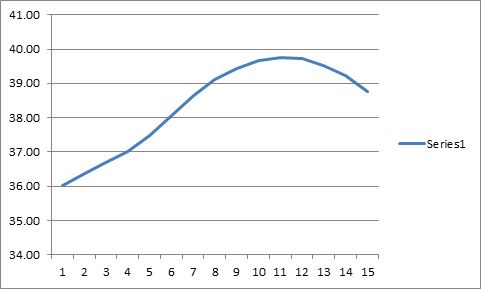

The graph shows that the velocity ratio (theoretically 290/8 = 36.25:1), gradually increases to almost 40:1 as a single (large wheel) tooth makes its transition. Then, as the ratio gradually decreases, surprise, surprise, the ration drops (from 38.77:1 to almost 36.25:1) as the next pair of teeth/pins meet.

I'm obliged to split this thread a second time …

Continued …

roy entwistle.