Is CAD for Me?

Is CAD for Me?

Home › Forums › CAD – Technical drawing & design › Is CAD for Me?

- This topic has 177 replies, 35 voices, and was last updated 27 June 2019 at 16:11 by

Nigel Graham 2.

-

AuthorPosts

-

6 June 2019 at 10:26 #412893

Nigel Graham 2

Participant@nigelgraham2Kiwi Bloke 1 –

Manual machines and software "behind" commercial rivals: "A bad thing"? No, not necessarily at all.

If the machine or software does what you need it to do in a manner satisfactory to you, the age of its concept or reality are not important. And many of us have no real choice anyway, when pecuniousness alloweth not even a small NC machining-centre.

Really, much of the development in modern engineering tools and methods is concerned with increasing commercial production efficiency as much as improving the products physically. As was thus 100 years ago, too.

Of course we can adopt modernity in our home workshops. Many model engineers now use CAD to form machine-controlling files, either to purchase cut profiles, or indeed for their own CNC machine-tools.

There have been letter-exchanges on the philosophy in ME (I don't if they've also appeared in MEW), but I see reductions to artificial "purity" by personal taste miss the essential point of a creative hobby. I regard us as making things for the joy of making and usually too, using, them; and that includes acquiring the skills to achieve the aim. Whether you choose or need to use manual drawing and old machines, somewhere in between, or all-CAD/CAM, each route requires considerable skills of its own.

You impress by, say, cutting your own gears for a miniature traction-engine, but unless you are after the big-name trophies, few would seriously object if you copy modern manufacturers by buying appropriate stock gears and machining the bores and keyways to suit. For a "non-model", e.g, workshop equipment, or miniature-railway passenger-truck, it is entirely appropriate to use modern methods, fittings etc. you would not use or could not disguise on that traction-engine.

My own machine-tools are all conventional and Imperial, though I am fitting a DRO set to the mill, readily enabling both mm and inch work. By completing one axis at a time it's already helping make the brackets for the next axis!

[Imperial machines… Fine, but SIX tpi on two of the leadscrews, 8tpi on the third, on my Denbigh H-series horizontal mill? Anyone any ideas why?]

On drawing methods, manual drawing may be very satisfying intrinsically, but CAD's potential is the time invested in learning it, ultimately releasing more precious leisure-hours to turn the design idea into reality – whether on antique machine-tools, or modern CNC versions.

6 June 2019 at 11:10 #412900 Michael GilliganParticipant@michaelgilligan61133Posted by Michael Gilligan on 05/06/2019 13:14:59:Posted by Nigel Graham 2 on 05/06/2019 11:43:11:

Michael GilliganParticipant@michaelgilligan61133Posted by Michael Gilligan on 05/06/2019 13:14:59:Posted by Nigel Graham 2 on 05/06/2019 11:43:11:… I tried that Mintronics site again with the same result, and since most web-site links do work from here (except embedded e-mail addresses) it could be tripped by a security software quirk. Or, possibly, some mis-match if Mintronics use MS-WIN10 and my PC is on WIN 7 Pro?

.

Did you try the link that I provided ?

MichaelG.

.

I'm bumping this, just once, because I have seen no response from you, Nigel

There has been a lot of discussion since I posted, so perhaps you missed it

… or maybe I'm on your 'ignore member' list

MichaelG.

6 June 2019 at 12:11 #412909Nigel Graham 2

Participant@nigelgraham2Michael Giiiigan;

Re Mintronics link etc.

Sorry, I wasn't trying to ignore you.

The whole discussion has become a tangle of different conversations, with notifications appearing in my e-post list randomly, and so I missed your post.

I did indeed find Mintronic's Alibre Atom page, possibly not by quite how you suggested, and I posted a direct quote from it as it might help others. It announces a new version and prices to come, plus possibly one-day courses. Prices with VAT and rounded, £240 alone; £360 with support.

At least I thought I'd posted it but I can't see it. I might have become logged out of the whole site without my realising it.

I'd also commented that whilst I understood others' suggestion I change from TurboCAD to Alibre, I don't know if the [.tcw] drawings I'd want would be transferable to Alibre; and the combined cost of Alibre + the abandoned TurboCAD, makes the change an expensive gamble. A gamble because I can produce rather rough but workable 2D drawings in TurboCAD and leave its optional 3D side as useful if I could learn it, but Alibre jumps right in at the 3D deep end with no guarantee I can learn that either.

6 June 2019 at 12:14 #412910Nigel Graham 2

Participant@nigelgraham2" Giiiigan " ??

Sorry – Gilligan. With ells not ayes. Now you know why I won't use lap-tops and so-called " smart "- 'phones " !

6 June 2019 at 12:17 #412911 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Thanks, Nigel

MichaelG.

7 June 2019 at 10:17 #413071Nigel Graham 2

Participant@nigelgraham2Having thought about what others here have said, I tried Alibre's "Free Trial Version" again…

It failed on a "trial period ended" notice. It took me a few minutes to twig this was because I had previously installed it in line with the MEW series.

Mind you, it didn't tell me this until I'd sat patiently waiting for it to set itself up.

Oddly, the programme itself is all there, just switched off; but not the accompanying pdf exercise book. Or if it is, it's in a very obscure folder I have yet to find.

(This exercise models a Hookes' Joint arrangement that if made physically would be a mere "executive toy", though would show why universal joints have to be used in pairs!)

+++

I had another go at a 3D TurboCAD exercise, a 2-throw crankshaft similar to that for my wagon engine. I tried a subtractive method as potentially feasible.

It looked promising but failed when I tried to change something part-way through. TurboCAD lets you produce simple " Primitive " solids like cylinders directly, but doing anything to them automatically dissolves them into " TC Surfaces " – polygonal prisms of adjacent but independent facets, so the former " solid " cannot be edited. An extruded cylinder from a circle is a TC Surface by default.

Now a crankshaft with disc webs is a chain of symmetrical, simple cylinders of known sizes, so can be assembled by calculating their centre co-ordinates. If the assembly is of more complicated, varied, unsymmetrical elements and sub-assemblies, such calculations become just too difficult.

So just don't expect me to model the rest of the engine around the shaft!

This leads to a particularly disheartening aspect created unwittingly by the CAD manufacturers' web-sites. Understandably they illustrate what their software can be used to produce; but obviously by staff draughts-people using its most advanced techniques to the limit, far beyond anything I could be fairly expected to achieve.

7 June 2019 at 11:19 #413080Nick Wheeler

Participant@nickwheelerNigel, you're STILL thinking in separate 2d drawings!

Model your crank main journals from one long properly defined cylinder. Do the same for the big end journals, mapping them around the end of the main journal. Then add the webs, positioning them with your dimensions. With some practice, you could reuse one web as many times as you need. Have the program join each new feature to the existing ones. Then have it cut away the joining parts you no longer need. The longest part of the job will be positioning the webs.

7 June 2019 at 11:43 #413085David Jupp

Participant@davidjupp51506Nigel – the PDF exercises for Alibre products are on the Alibre web site (Help & Learning area).

I'm not able to find any record of a trial for you in the licensing system (searching by Nigel, or by Graham) – so am not able to renew or extend trial (PM me some details if you'd like me to search again).

7 June 2019 at 11:47 #413087Baz

Participant@baz89810Maybe MEW should continue the Alibre Atom series with a series of how to draw a two throw crankshaft and perhaps an expansion link and also a cylinder block with ports and passages in, this would be of more practical use to a model engineer representing things he will be interested in making, just my 2p worth.

7 June 2019 at 12:04 #413094SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 07/06/2019 10:17:54:

…

Now a crankshaft with disc webs is a chain of symmetrical, simple cylinders of known sizes, so can be assembled by calculating their centre co-ordinates. If the assembly is of more complicated, varied, unsymmetrical elements and sub-assemblies, such calculations become just too difficult.

So just don't expect me to model the rest of the engine around the shaft!

This leads to a particularly disheartening aspect created unwittingly by the CAD manufacturers' web-sites. Understandably they illustrate what their software can be used to produce; but obviously by staff draughts-people using its most advanced techniques to the limit, far beyond anything I could be fairly expected to achieve.

Crankshaft calculations may be too difficult for the average Joe, but it is possible. One of the advantages of 3D CAD is the tool may be able to help, perhaps even doing the whole calculation.

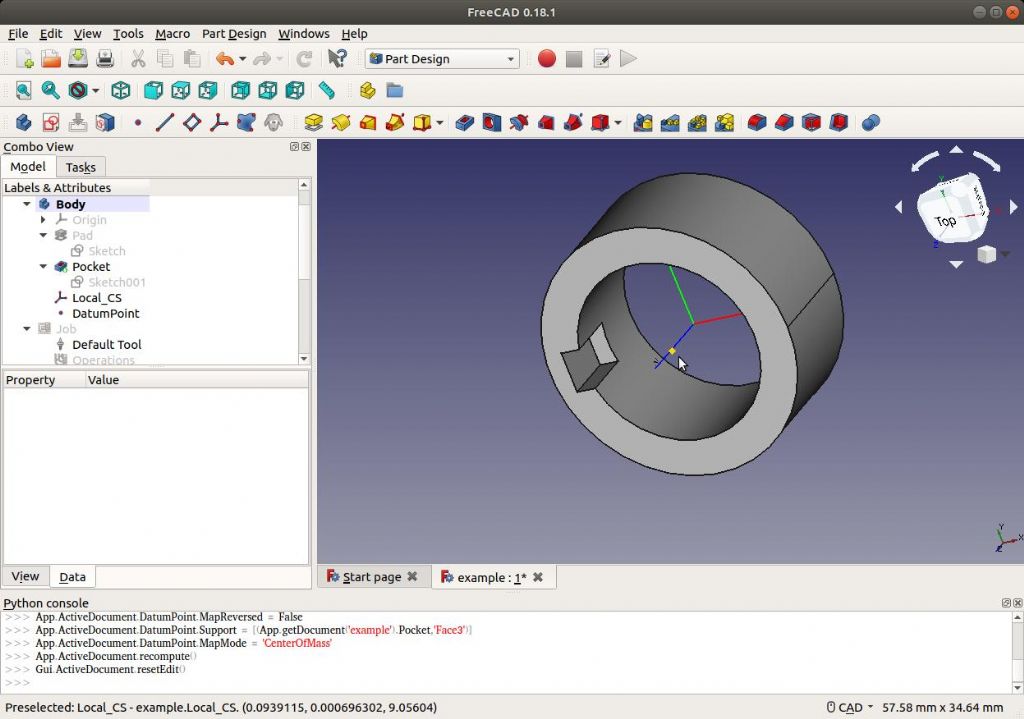

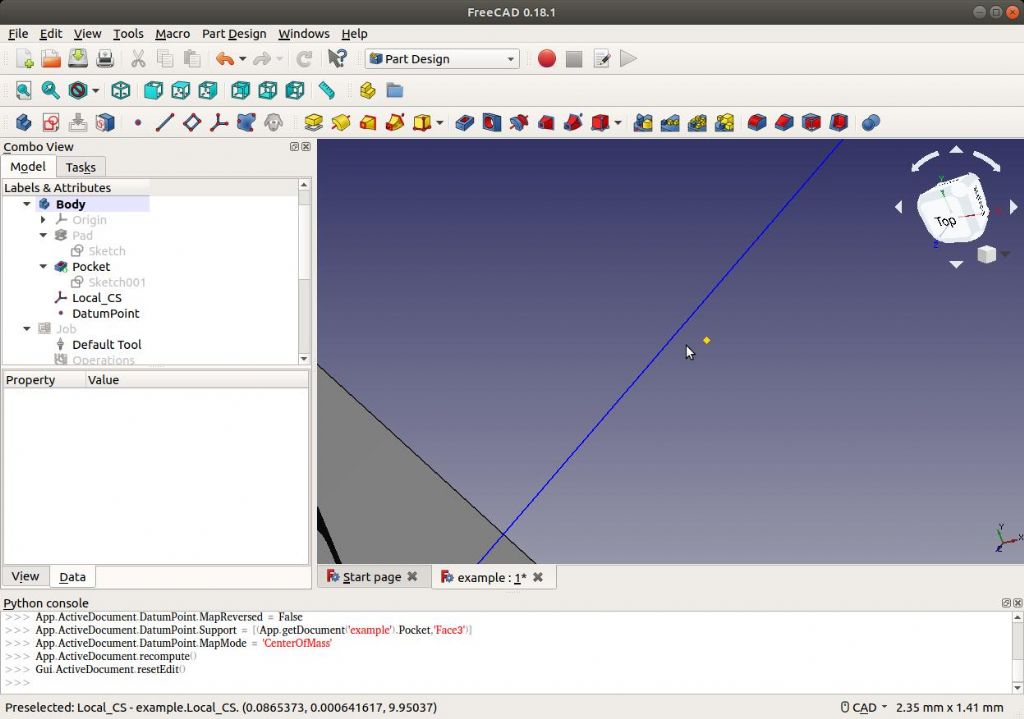

I didn't expect FreeCAD to have much to offer, but it has part of the answer. Maybe more if I looked harder. My cylinder example would be balanced about the axis of rotation (Z in the example) were it not for the notch. FreeCAD can tell me where the objects Centre of Gravity is, yellow dot near the mouse pointer:

Zooming in shows the C.O.G isn't on the Z axis:

I could measure how far off the Centre of Gravity is and use that to calculate a counter-balance. Or I could add or subtract lumps from the cylinder until the yellow dot sits 'close enough' to the biue line. Or, if it doesn't exist already, I could write a Python Program to search for optimum balance. These methods would only address static balance, but someone who knew the ropes could program to optimise dynamic balance. In the not too distance past engineers would do this with teams of people doing the sums and testing the result with a real model. Now months or even years of work can be done in seconds.

This is grown-up stuff. You can't expect to do it without a good understanding of the problem, knowing whether or not your software supports that kind of problem, and of course – knowing how to drive the tool to get the right result. Learning how to do this requires substantial time and effort.

Another job the these tools can do in a fairly straightforward way is Finite Element Analysis. FEA shows where stress occurs in a loaded structure and identifies where that stress is too much for the material. It finds weak spots so they can be strengthened, and it highlights over-strong spots that can be removed to reduce weight. The ability to do this is very useful to anyone designing a crankshaft.

You said ' Understandably they illustrate what their software can be used to produce; but obviously by staff draughts-people using its most advanced techniques to the limit, far beyond anything I could be fairly expected to achieve.' Of course these tools are demonstrated by experts! Stradivarius would never have sold a violin by asking a random passer-by to demonstrate its merits.

But I think you're doing yourself down by believing using them is 'far beyond anything I could be fairly expected to achieve.' More likely you don't have the time and patience needed to break into 3D-CAD properly. I notice you're trying learn TC by modelling a crankshaft. That's an advanced object when you don't quite know the ropes. Like almost every tool, it's better for beginners to explore complex software by keeping it simple at first.

Another mistake is to leave long gaps between sessions. My poor old dad failed utterly with his mobile phone because having had stuff explained, he wouldn't try it for a week or three, by which time he'd forgotten the lesson. By not getting stuck in he destroyed his self-confidence. Ironically I've developed the exactly same problem with Smart Phones…

Dave

Edited By SillyOldDuffer on 07/06/2019 12:06:54

7 June 2019 at 12:10 #413095 John HinkleyParticipant@johnhinkley26699

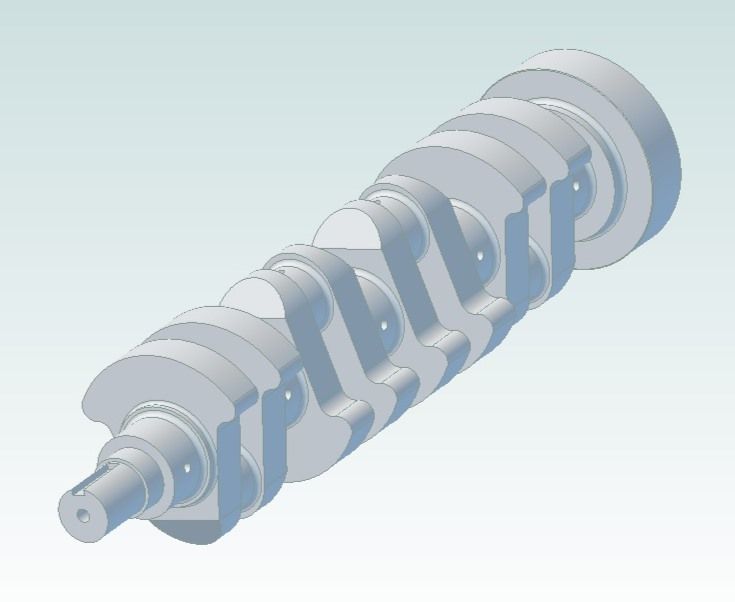

John HinkleyParticipant@johnhinkley26699Like Nigel, I tried many 3D CAD programs and couldn't get to grips with any of them, at all. After a longish break, I decided to give the Alibre Atom package a go. I had to virtually forget EVERYTHING that I'd applied to 2D drawing ( I have no training or work experience in technical dawing ) and start from scratch. I determined to "make" the parts as if I was constructing them from stock material. For example, I started to design a 4-cylinder engine and started with the crank, starting at the front and progreesively adding webs and bearing journals, etc, until I had a complete part. It didn't take long at all and in the end looked like this:

It shouldn't be too difficult to draw a two-throw crank with simple constructional steps in a similar manner, I wouldn't have thought.

I'm not saying that this is the best, or only way, to do it, just that this is how I approached the "problem" of getting my head around the concept of 3D drafting. With hindsight and now with more experience with the Atom program I would have used a slightly different approach and used for example, the "mirror" tool to replicate the crank webs instead of producing each one individually. ( I've redone it this way since. )

Persevere, Nigel. I promise it is both rewarding and satisfying when it finally "clicks" and you produce an aesthetically pleasing result.

John

7 June 2019 at 13:16 #413113Nigel Graham 2

Participant@nigelgraham2Baz –

Interesting point that. Not necessarily engine parts but certainly items of clear interest that could become useful reality – e.g. simple workshop tools and accessories.

'

David –

Thank you. Ah, that seems odd then. I'd taken the trial version straight from Alibre's (or Mintronics' ? ) site opened by a direct browser link, so I don't know if Alibre or its agent has a register separate from the magazine's.

Thank you for kind offer but given the gamble, I think it wiser to stay with TurboCAD. If I am forced to use only its 2D mode, I'll have to accept the frustration but won't have lost any more than the time already spent.

Even with Alibre's trial version, I'd be faced with a new, totally different, 3D CAD system from scratch. If I can't master that either, I'll have wasted hours on what will last only 6 months anyway. If however Alibre is saying I've have no choice but outright purchase, I'd almost certainly end up losing both many hours and £240.

'

Nicholas –

I can assure you I was trying to work in 3D!

By subtraction though, and co-ordinate arithmetic, as I cannot use the intended assembly methods.

I'd imagined I was cutting the shaft from a billet of steel 2.5" dia for its full length. After a few goes at establishing the right order, I subtracted an annulus from each end of the ' Primitive ' cylinder to leave the end journals. As I wanted, it now looked like a rolling-pin.

Step-by-step and similarly, I removed the " metal " around each crank-pin:

I drew the pin " within " the billet, then copied it in place twice; colouring the copies to guide me. I kept copy 1 as-is, enlarged copy 2 to about 4" dia to cover the throw, then subtracted copy 1 from 2. Finally, subtracted copy 2 with " pin hole " from the billet, to expose the original pin. All correct so far.

It went to rats somewhere after that, including something that changed the shaft from a generated cylinder to a strange, intractable " TC Surface ". I don't know what that is geometrically. Nor if TC there stands for TurboCAD or something else.

This was all in 3D mode, using the various viewing angles to verify progress – until it went wrong.

My later thought about mapping the features' co-ordinates was forced on me by TurboCAD's baffling 3D assembly methods: abstruse combinations of various entity-types, tools, etc. Using such mapping works with straightforward, symmetrical objects, but breaks down with increasing complexity.

7 June 2019 at 13:24 #413118 JasonBModerator@jasonb

JasonBModerator@jasonbIs the scribing block not a useful workshop tool and of interest to model engineers? Also bear in mind that MEW is not the sole preserve of Model engineers, plenty of home workshop users not interested in models

I tend to do crankshafts a piece at a time rather than subtracting from the solid, infact I do that quite a lot as parts are often fabricated from more than one piece rather than cutting from solid

7 June 2019 at 13:28 #413120David Jupp

Participant@davidjupp51506Nigel – if when taking the Alibre trial something got mis-typed, that could explain why I can't find you (this is in the master licensing system where everything ends up, regardless of where it originated).

If you should change your mind and want to have another go – PM me your trial code (if you took the extended trial), or the e-mail address that you used when activating the trial.

7 June 2019 at 14:27 #413127SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 07/06/2019 13:16:03:

…

It went to rats somewhere after that, including something that changed the shaft from a generated cylinder to a strange, intractable " TC Surface ". I don't know what that is geometrically.

…

I've suffered 'going to rats' symptoms myself, both in FreeCAD and Fusion360. In both cases, as a learner feeling my way, I was creating objects that looked OK, but were incomplete or inconsistent. Production glitches don't matter unless something depends on them later, but as the model develops these omissions cause the software to behave unexpectedly as it tries to display a faulty structure. Bit like doing a Sudoku puzzle were you suddenly hit a contradiction caused by an earlier mistook. You have to backtrack.

FreeCAD and Fusion both maintain edit timelines. Fusion's is along the bottom of the screen and it rather helpfully puts yellow (warning) or red (broken) triangles on any earlier step that's in trouble. FreeCAD is less obvious but opening up earlier steps often reveals a new error message. Correcting the problem usually flows up the timeline and restores sanity. TurboCAD may have a similar facility, but it needs a TurboCAD expert to know. The TurboCAD forum might do better than this one.

Dave

7 June 2019 at 14:33 #413131Nigel Graham 2

Participant@nigelgraham2JasonB _

Sorry – I can't see your post actually on this thread, and my e-mail system send notifications randomly. Anyway, you wrote:

" Is the scribing block not a useful workshop tool and of interest to model engineers? Also bear in mind that MEW is not the sole preserve of Model engineers, plenty of home workshop users not interested in models

I tend to do crankshafts a piece at a time rather than subtracting from the solid "

'

With respect, you've missed my 2 points there though a scribing-block is indeed more useful than the strange contraption Alibre uses as an exercise.

It does not matter what is being drawn, nor by whom and for what purpose beyond the drawing, as the object of the exercise is how to draw it by CAD.

My choosing to draw a crankshaft has nothing to do with how to make it beyond knowing it can be made to that design.

I chose it purely for its geometrical and CAD properties as a series of symmetrical, simple entities; and I have tried drawing it both by assembling those entities (the 'approved' CAD way I gather), and by subtracting.

And I drew in the latter way not necessarily because I might make it that way, but to find a drawing technique I could use that is easier for me than by drawing by assembly.

7 June 2019 at 15:02 #413137Anonymous

Posted by Nigel Graham 2 on 07/06/2019 14:33:10:My choosing to draw a crankshaft has nothing to do with how to make it beyond knowing it can be made to that design.

Therein lies part of the problem. When drawing in CAD the method of manufacture of the part should be uppermost in the mind. There are three ways to create a crankshaft:

- Create a single part making cylinders and webs in sequence until the crankshaft exists as a single part

- Create individual parts such as cylinders and webs and then put them together in an assembly

- Start with an oversize block and subtract to create the crankshaft

Method 1 would be used if the crankshaft was to be machined from solid, so it is one part and a 2D drawing can be created for the part. Method 2 would be used if the crankshaft is to be built up; 2D drawings of each part can be simply made. Method 3 is similar to 1, but seems a rather odd way to do it.

Andrew

7 June 2019 at 15:24 #413140Nigel Graham 2

Participant@nigelgraham2No, Andrew, sorry but how to make a crankshaft it is not part of the problem at all!

The entire problem is purely whether I can learn 3D CAD modelling.

Of course I know you have to think how an object will be made in order to design it, but I am trying to concentrate simply on the drawing techniques.

If I had drawn merely a random string of cylinders of different sizes, no-one would have worried about what it is beyond what I intended: a drawing exercise!

Yes, I picked on something familiar, but I did not set out to worry how it would be made, and as drawn you can make how you wish.

I cannot use CAD to help me design anything until I know how to use CAD, but it's becoming clear I cannot learn itl.

7 June 2019 at 15:46 #413142 JasonBModerator@jasonbPosted by Nigel Graham 2 on 07/06/2019 14:33:10:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 07/06/2019 14:33:10:'

With respect, you've missed my 2 points there though a scribing-block is indeed more useful than the strange contraption Alibre uses as an exercise.

No You have missed the point.

MEW used a scribing block as a simple example to model. If you eventually find your way to the Mintronics site you will find an additional manual for about £11.50 which is a full length version of what was in the mag but with full size images not the much reduced ones in the mag. This manual if free to those who took up the MEW extended trial.

There are several forum members who having completed drawing the scribing block then went on to working through the crank/universal joint exercise and with a bit of help from the forum got it all to work. This is more advanced so won't help you with the basics.

Out of interest was your original trial of Alibre the extended 6mth MEW one or just the two weeks off the net, you would have needed a copy of the magazine to know the correct URL for the extended offer.

have you got a fag packet sketch or extract from what info you do have of this waggon, I'm sure one of us would draw it up in cad to point you in the right direction, seem to remember asking this of you a few nonths ago what the same issues were discussed but nothing forthcoming

Edited By JasonB on 07/06/2019 15:49:35

Edited By JasonB on 07/06/2019 16:11:04

7 June 2019 at 20:46 #413172Nigel Graham 2

Participant@nigelgraham2JasonB

Thank you for that offer of help.

First though, I know the scribing-block was simply an exercise! So was that crankshaft.

That does not matter. Most of my TurboCAD 3D drawings are merely simple geometrical figures, to try to understand how to use the programme. Real objects are for IF I can draw them.

I know I could have obtained the back-editions of MEW, and the offered manual; but I had lost heart by then and realised I am better with a scrappy knowledge of TurboCAD in 2D, than risking a complete new start with no real hope of better success.

'

I was in a sort of cleft stick.

Alibre Atom is totally different from TC. It was offered by Alibre hoping for sales of full versions to those who are confident enough from the MEW course, to take it much further.

I did not realise I'd missed anything until my first subscription edition of MEW revealed the gap in the Alibre serial. I thought I had started my subscription correctly, but the coversoon showed not.

I was finding TC's 3D world ever more confusing, and I feared any other CAD would be no better; with the text seeming to me the cosily reassurance of painting-by-numbers.

Select this, enter that value, click here… And it works, but what have I actually done or understood more fundamentally than following an exercise by rote?

Hence the cleft stick, if not trident. I bought TurboCAD in the first place partly because I wanted genuinely to draw in both 2D and 3D. I did not know then the experts insist on 3D-first then extract the elevations; but that might not have mattered. (I don't know if TurboCAD offers that – but it does offer the straight 2D/3D choice).

Do I catch up on Alibre with two possible outcomes, or cut my losses so far? My two likely Alibre outcomes would be completing that one exercise without understanding it, before the trial offer expired; or being lulled by completing the series into buying the costly full version then finding it too hard for any practical use.

TurboCAD 3D is too difficult beyond a very simple level of non-dimensioned pictures of little practical value, of very simple items. I had no guarantee, evidence or belief any other 3D CAD is any easier.

Yet I can produce just-adequate 2D drawings in TurboCAD, good enough for my own use; so why risk all that money and time chasing such an uncertainty despite my original wishes?

'

I have to admit I do not have the intellect for 3D CAD, in any make. It's just too difficult.

'

Regarding your kind offer, thank you very much but I have no information that would allow anyone to help me. I have to complete designing my wagon's engine and transmission, and details including the steering-gear and boiler fittings. Much of it is design-on-the-fly; I may have to re-work some areas made too many years ago. There are no extant works drawings, but I have found a model engine whose geometry is close enough to be adapted; and have its GA in hand, orthographic of course.

I don't recall that earlier discussion but I did appeal for some TurboCAD help when I temporarily lost contact with its users' forum.

I know that I cannot use 3D in designing any of what my own project still needs; but I am afraid someone giving me a nice 3D CAD image of it would only stress my own inability in such drawing .

7 June 2019 at 23:02 #413190Colin Heseltine

Participant@colinheseltine48622Nigel,

I feel your pain regarding Turbocad 3D drawing. I bought Turbocad several years ago and have been unable to get to grips with it. Having recently bought a 3D printer I want to be able to draw things up that I can print. I worked through the exercise in MEW but struggled a bit due to the size of the pictures in the article. I am red/green colourblind and this has caused a few issues not being able to see the colours of fine lines. Once I found I could increase the line widths I found things quite a bit easier. I found the concepts easier to grasp in Alibre than in Turbocad, especially selecting facets. I feel that with some practice it will become easier. I think it is more intuitive than TC.

I intend to work through the exercise again using the larger pictures in the .pdf rather than a large magnifying glass to read pictures in the mag, this was one of the things which slowed me down. I will also work through exercise on the web site.

I decided to bite the bullet and purchase a licence.

Baz's suggestion that MEW run other articles on Alibre 3D certainly would certainly appeal to me.

Colin

8 June 2019 at 10:27 #413221Nigel Graham 2

Participant@nigelgraham2Colin –

Thank you for the supporting comments! I was beginning to feel only I cannot learn something everyone else finds easy.

Yes, I find TurboCAD very non-intuitive. Very confusing, too.

Someone referred me to a TC 3D exercise whose subject was completely random, but with some useful concepts. Unfortunately it was for TC 15, too different from my 19 Deluxe edition to be very helpful.

Another problem is the TC 19 Deluxe's own " manual ". It is very poorly, haphazardly written and arranged, explains little, even contains notes on tools it admits not in that version of TC! Being a .pdf document, you cannot search it by text, only page number. However, I overcame that by making a printed, alphabetical index to it.

Fusion deterred me completely. I completed the first Alibre instalment, missed the next two, could have caught up but see no advantages in that; and frankly, now think any 3D CAD system is beyond me.

'

Colour-blindness: May I make a suggestion? This won't help you read the drawings in the magazine, but for your own creations, could you select from the available palette colours you can differentiate easily, and note their names, for regular use? This would particularly help if Alibre allows custom templates as TurboCAD does, including I think, line thicknesses and colours.

'

Baz' suggestion: I agree in principle but really its examples ought cover a reasonable range of interests within model-engineering, and be paralleled by articles in other editions for TurboCAD and Fusion. The exercises can be from real projects but should be seen as just CAD exercises. It would be worth stressing that expertise in CAD can trap you into designing objects difficult or impossible to make – even professional draughts-people fall into that trap.

I don't know of any other worth-while CAD makes used by amateur engineers. SolidWorks is used widely in industry but not sold to hobby users; AutoCAD is similarly limited… and no doubt both are commercially "economical"! I think this only from their web-sites: it might be worth asking them.

8 June 2019 at 11:41 #413232David Jupp

Participant@davidjupp51506Graham,

Alibre has several built in colour schemes, you can edit these and also set up you own custom colour schemes. I get that you aren't going to try again with Alibre, I just mention it for the benefit of others who may have restricted colour vision (or just don't like the standard choices).

8 June 2019 at 17:15 #413272Nick Hulme

Participant@nickhulme30114I started using CAD/CAM at 50, get stuck in, if you have the drive to do it you will succeed!

8 June 2019 at 17:46 #413276Enough!

Participant@enoughJust a thought: are there no CAD training courses available for a reasonable cost at local educational establishments?

I learnt CAD professionally (Pro/Engineer …. and if you want to see unituitive ….) about 25 years ago when the company I was working for introduced it. Companies are not about to pay people to pick it up on the fly so to speak. They send you on a training course where you get graduated professional instruction which is much better. In particular you can ask questions to address those mental blocks that arise.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

TurboCAD – Alibre File Transfers.

1

2

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 8

- 26

-

15 July 2025 at 01:38

Nigel Graham 2

-

Silver steel crankshaft

Started by:

teamricky in: Stationary engines

- 7

- 21

-

15 July 2025 at 00:25

teamricky

-

Volt/amp meter

1

2

Started by:

duncan webster 1 in: Electronics in the Workshop

- 15

- 42

-

14 July 2025 at 23:26

duncan webster 1

-

Error-Message of the day

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 8

-

14 July 2025 at 23:20

Clive Brown 1

-

Electronic leadscrew pitching error

Started by:

paulg 1 in: Introduce Yourself – New members start here!

- 4

- 13

-

14 July 2025 at 21:46

Robert Atkinson 2

Robert Atkinson 2

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 104

-

14 July 2025 at 21:26

Dalboy

-

Another Day … Another ScumBag

1

2

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 15

- 35

-

14 July 2025 at 21:19

bernard towers

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 9

- 10

-

14 July 2025 at 20:00

old mart

-

Screw cutting 1.25mm pitch on a Colchester Student.

Started by:

Kevin Nicholls in: Manual machine tools

- 7

- 16

-

14 July 2025 at 19:03

bernard towers

-

“swedish iron”

Started by:

moonman in: Materials

- 15

- 19

-

14 July 2025 at 17:46

John MC

-

Variable DC power supply?

Started by:

Andrew Tinsley in: Electronics in the Workshop

- 4

- 10

-

14 July 2025 at 17:27

Andrew Tinsley

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 20

- 42

-

14 July 2025 at 11:41

Bazyle

Bazyle

-

Boiler Design – issue 4765

1

2

…

8

9

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 201

-

14 July 2025 at 10:06

JasonB

JasonB

-

Indicators – vehicle

Started by:

Speedy Builder5 in: Electronics in the Workshop

- 4

- 6

-

14 July 2025 at 06:02

Speedy Builder5

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 16

- 20

-

14 July 2025 at 02:13

Neil Lickfold

-

Electroplating questions

Started by:

Baldric in: Help and Assistance! (Offered or Wanted)

- 3

- 3

-

13 July 2025 at 13:42

noel shelley

-

Difficulty in sourceing 2.5mm s/s ‘Full’ nuts

Started by:

Greensands in: General Questions

- 7

- 12

-

13 July 2025 at 09:22

Roger Woollett

-

Rotary valve engine

Started by:

AStroud in: Stationary engines

- 2

- 3

-

13 July 2025 at 08:49

AStroud

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 12

-

13 July 2025 at 06:50

Diogenes

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 17

- 31

-

12 July 2025 at 22:00

Howard Lewis

-

Help for DIY lathe build.

1

2

Started by:

moogie in: Help and Assistance! (Offered or Wanted)

- 16

- 36

-

12 July 2025 at 21:42

Howard Lewis

-

New Member From The Isle of Man

Started by:

sprocket 3 in: Introduce Yourself – New members start here!

- 4

- 4

-

12 July 2025 at 20:57

Howard Lewis

-

The Silver Swan Automaton

Started by:

James A in: Related Hobbies including Vehicle Restoration

- 3

- 5

-

12 July 2025 at 18:46

James A

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 607

-

12 July 2025 at 16:28

Turbine Guy

-

Nozzle dot dwg

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 1

- 1

-

12 July 2025 at 14:47

Michael Gilligan

Michael Gilligan

-

TurboCAD – Alibre File Transfers.

1

2

-