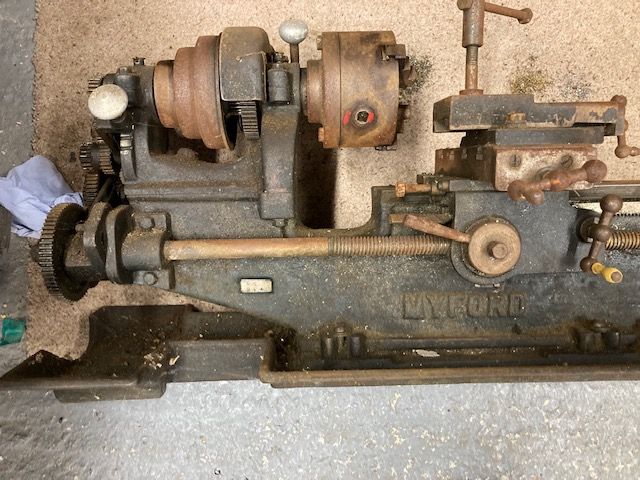

Lathes UK devote a few pages to the Myford Ml1,2 3 and 4.

If the centre heightbis 3 1/2" it will be a 3 or a 4.

(! and 2 were 3 1/8" )

The mahoritynof threads will be 1/4 BSF, with a mfew BSW (5/16 and either 1/8 or 3/32 from far distant memory )

Gib adjusters may well be BA.

The earlier models had stabdard 7/8 BSW (9tpi) mandrel theras, many had 7/8 x 12 tpi, and I think that a few of the last ones had 1 1/8 x 12 tpi, but not the 1 1/4" register used on the 7 Series.

It might be mworth making an adaptor with a 7/8 thread to suitb the Mandrel and an external 1/1/8 x 12 tpi, with 1 1/4" register so that chucls, Faceplates etc for the 1947 onwards 7 SEries can be fitted.

Don't forget to puyt on two flats so that the adaptor can be screwed onb or more importantly, off!

There were two two types of gear cover. The more usual typ hinged on a horizontal bar in a castong fixed to mthe back of the Headstock, while the less common variety hinged in the vertical plane.

Gears ar, like the later 7s, 20 DP, 14.5 PA, and 5/8 bore, but are drivem driving collars, and compounded by 3/32 pins. The laterb 7 Series used keys.

A 7 Series gear can be used on an earlier ML4 by drilloing the 3/32 hol thriugh and using that as a drillinbg jig for a 7 Series gear.

The holes should not go right through so that bthe pin does fall out, so the hole in nthe "jig" gear might need blocking..

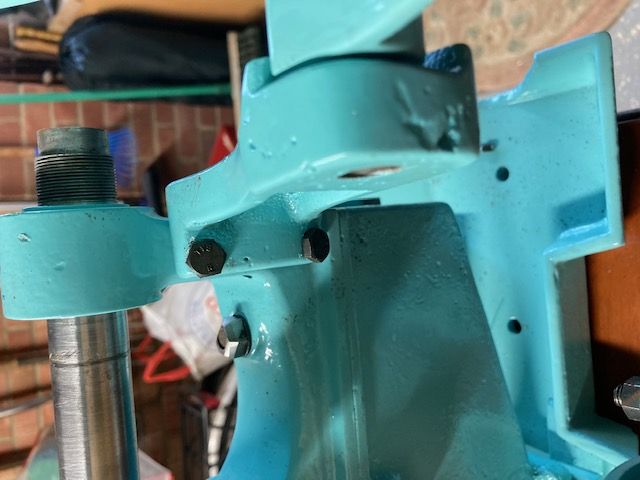

The Tailstock barrel is, or should be, prevented from rotating by a 1/4 BSF grubscrew with a key on the nd. Consequently the setting can be a bit of a "suck it and see" affair until the grubscrew is screwed in too far and jams the barrel. Then back off 1/2 turn and refitb the plates that restrain nthe handwheel!

HTH

After thought. If you get an eatra 20T or two, you can set up a fine feed using bthe8 tpi Leadscrew. 20:60/20:65/20:60 (This prevents any clash between the two 20:60 meshes. Rhe banjo may need a bit of fettling at bthe Mandrel end to allow the first stud to give the correct mesh between the 20T driver and the first 60T

I set backlash, starting at the Leadscrew end, by running a piece of paper (About 0.003" )through each mesh, to give minimum backlash, and then work my way back to towards the mandrel, swinging the banjo to set the final backlash with the 20T driving gear.

Howard

Edited By Howard Lewis on 20/02/2023 17:21:36

Howard Lewis.