being pessimistic, have doubts about bthe stregth of the repair.

BUT, if you use your lathe to make a new one, the brazed D H lock might last long enough for you to complete the machining, and so be able to fit a replacement locking device.

It might even be worth extending the machining on both sides a little further towards the holes.

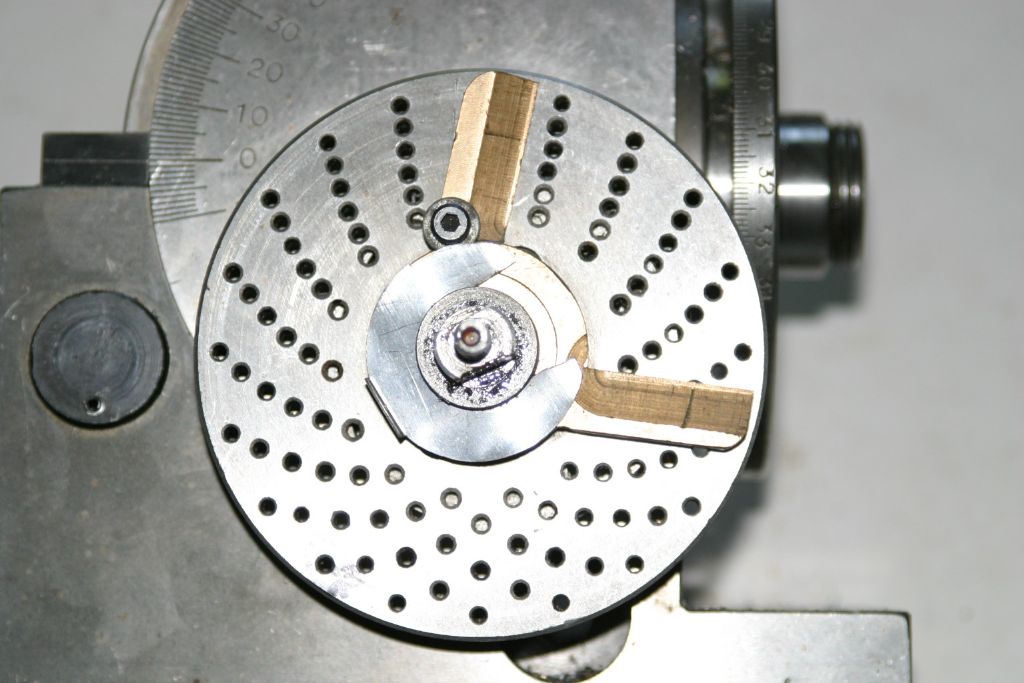

FWIW, I would suggest making the bore as close a fit on the mating part as possible, to minimise the bending of the arms. It might be worth extending the depth of the slot until it intersects the solid part of the clamp, to make the arms more flexible and to move the point of bending.

The worm is likely to be single start, so if you count the teeth on the wormwheel, that should tell you the ratio, which will be a start.

Somewhere on here, there was a spreadsheet showing the calculations for a Rotary Table with a 90:1 ratio.

Serach for HV6, spreadsheet. That should allow you to find and copy the spreadsheet, so that ikt can be edited to suit your purposes.

If you copy it and amend the formulae from 90:1 to the ratio of your DH,you should be able to construct, and print a chart showing the divisions available from your DH and the division plates that you have.

Good Luck!

Howard

Howard Lewis.