Posted by Adam Harris on 01/07/2014 18:25:47:

……………….. is if someone could list which tips they personally recommended on model engineering lathes for which type of cuts (roughing out, medium or finishing) for which materials.

A lot will depend on what you term a "model engineering lathe" I know someone who ises insert tooling on a little Cowells lathe and they also have a Colchester Master in the shed and several other lathes in between, all used soley for hobby model engineering.

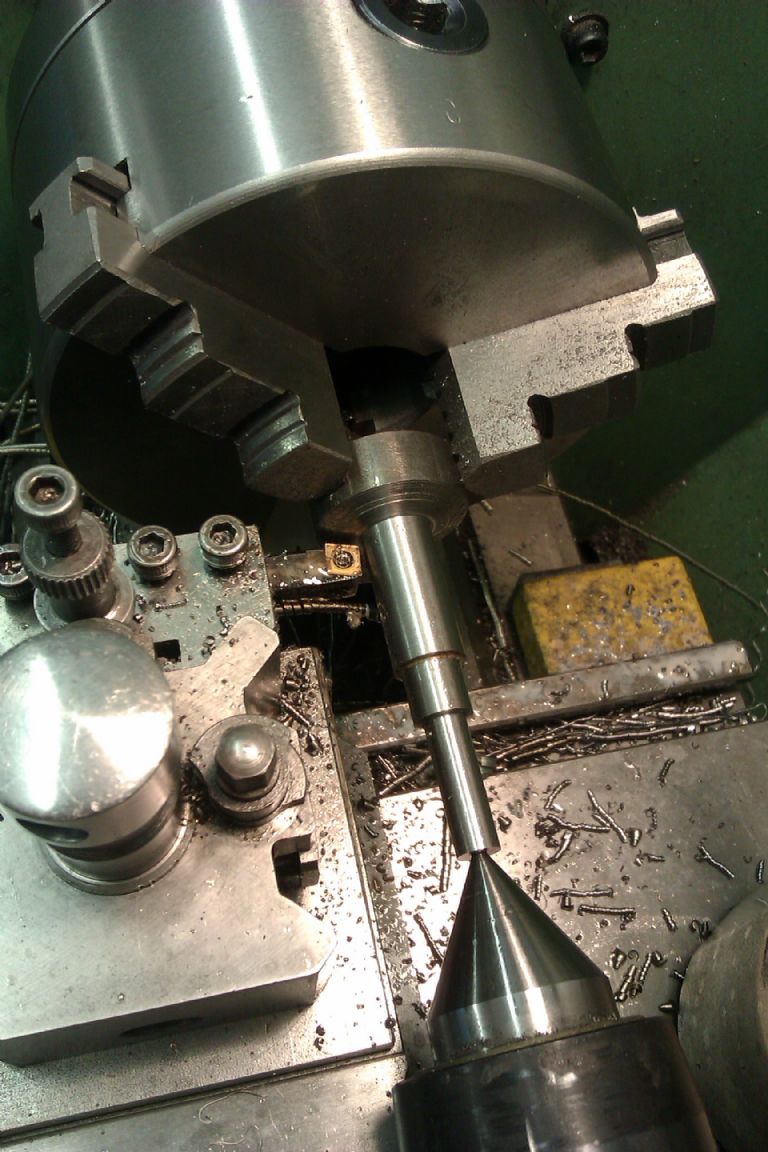

This is what I'm currently using on my Warco WM280, which is a bit bigger than a myford but if you believe what you read about imported lathes not as tightly made!!

Aluminium, Brass & the Bronzes CCGT tips, I'm still on teh Chronos ones I bought about 2 years ago but do have some Sumitomo one for when if they wear out as they are lasting very well, I keep one in a RH holder and another in an 10mm boring bar all the time.

Steel for most general work I'm using Kennametal CCMT 060202LF inserts which have a small 0.2mm radius tip and as the LF (light Finishing) signifies are good for lighter cuts, I can easily take 0.001" depth of cut off steel with these unless its very long and slender. They will still quite happily take 0.050" cuts as well. I always have these set up in the following quick change holders, R/H, L/H and two boring bars

For roughing out I don't use a specific insert but I do have one of teh holders that allows you to use the two "spare" corners of the CCMT inserts, as these are an obtuse angle they are a bit more durable and it allows you to get your monies worth out of the inserts, one always ready to go in a holder for the QCTP

For chunky iron castings I do have some similar CCMT 060208 again by Kennametal which are a bit more durable due to their 0.8mm tip radius though not much good on my machine for fine work

For parting in all metals I have a Glanze holder and thats still on their standard 2mm GTN tips. Have also recently bought one of the Mini-thin holders which are great for small grooves such as those needed for "E" clips Both in their own QCTP holders plus two other HSS parting tools

I also have a 6mm button type tool again from Glanze with the original bits but don't use it a lot

And for getting into tight spots I have a reversible L/H & R/H holder for the more pointed DCMT tips

Plus a load of HSS and some Brazed carbide only one R/H tool thats permanantly in an extended holder and ready to go, others used as needed

Unfortunately I can't quantify the finish like Andrew as I don't have a surface comparitor but here are a few shots to show what comes straight off teh tool.

Roughing EN8

And the ringlets of swarf from the 0.050" DOC, notice how they have been thrown away from the finished surface which I believe is a sign that the tip is working correctly

Bit of Ali done with a CCGT

Iron Casting done with 0.4mm radius CCMT

J

Edited By JasonB on 02/07/2014 13:35:57

Adam Harris.