In bending, half of the tube is in tension and half in compression, so concrete isn't going to help a great deal, especially if there is nothing stopping it simply moving along the tube on the compression side.

Similarly, filling the tube with resin etc and compressing it will simply increase the hoop stress on the circumference (and very marginally at that – think of the stress in the studding vs the minimal stress you would generate in the tube itself) but do nothing for the axial / bending stiffness itself, even if it is somehow firmly anchored to the inside wall of the tube. Making it into a pressure vessel won't make it stiff although ultimately it would bring it closer to yield in bending.

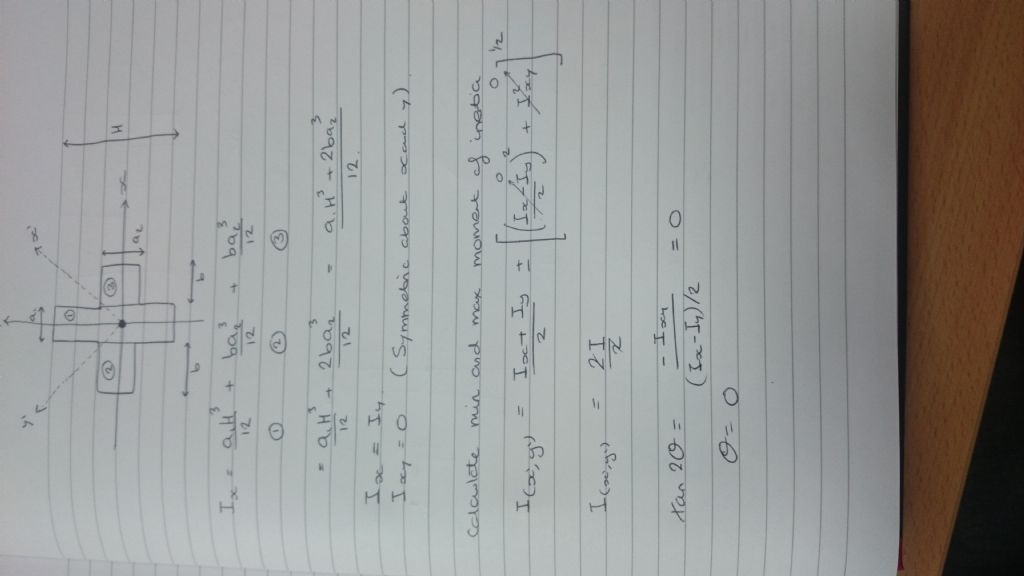

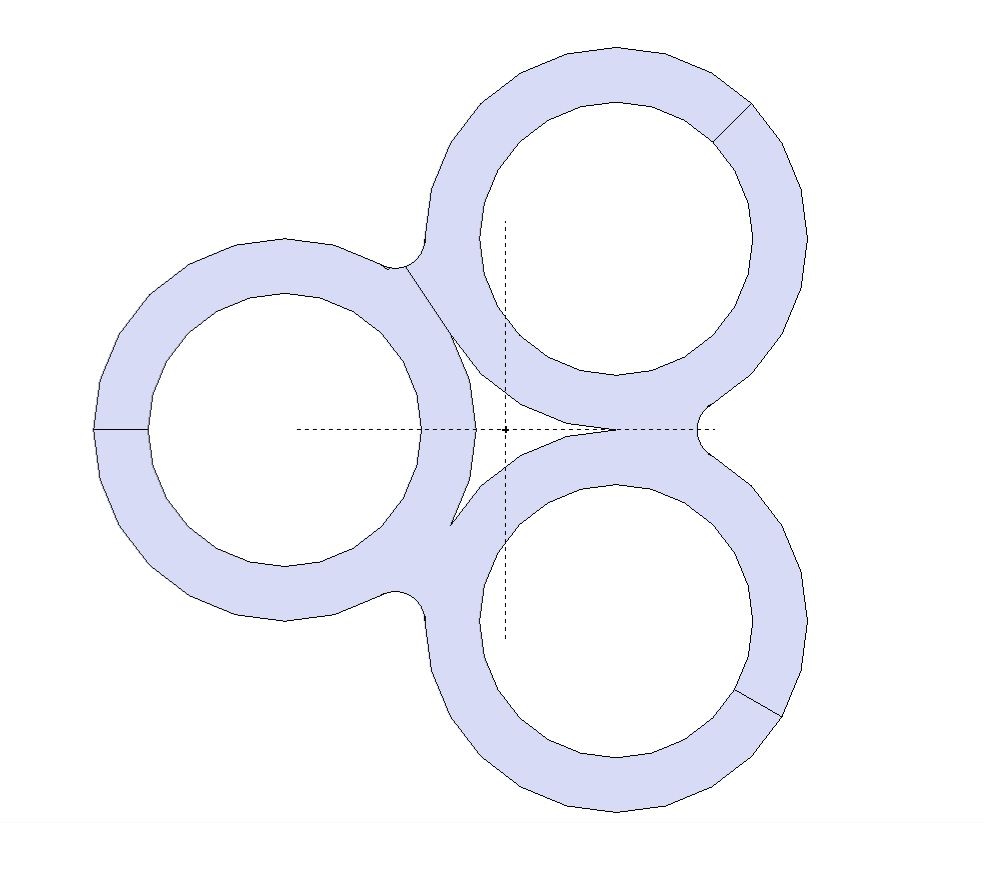

I can't imagine how you'd weld these stiffening members inside the tube or why you'd want to. I hear you say it's just a discussion but as pointed out, the stiffness is related to the second moment of area ie fourth power of radius, so surely the lesson is that if your application needs more stiffness, go for a thicker walled (or solid) pipe. If you are determined to use up your thin walled pipe, it's going to bend something rotten before it collapses. Are you stuck on a desert island?

Merry

Ady1.

Ady1.