Hi Ady1

Some back of the envelope thoughts and musings re your drill press or machine……

I ran A computer program to test for deflection with a load of 35kg applied laterally at the unsupported end of a 500mm hollow steel tube, over a few different sizes and got:

1.28mm with a 35mm 5mm wall tube.

.97mm with a 35mm 12.5mm wall tube. (Note wall thickness 10mm hole in centre)

.39mm deflection with a 50mm x 5mm wall tube

.11mm deflection with a 75mm x 5mm wall tube

.04mm deflection with a 100mm x 5mm wall tube

To completely "fix" a tube (beam) to an unyielding support structure is difficult, there will most likely be some flexure at the fixed end connection, this would increase the deflections mentioned.

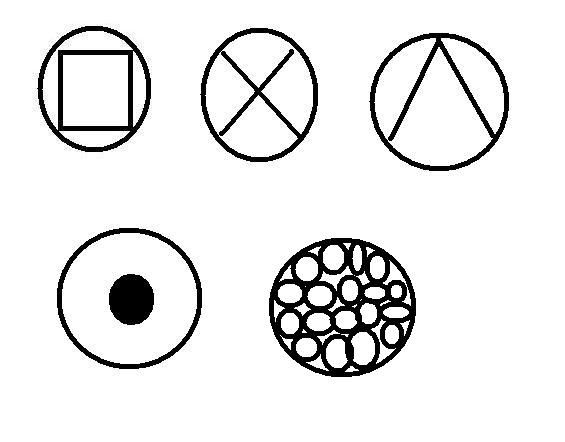

As the numbers show, Increasing the diameter has a much greater effect on the stiffness then making the walls thicker. When a beam is subjected to a load the stresses on the load side of the beam are in tension while the opposite side is in compression. The centre of a beam is sometimes called the neutral axis, the closer to the centre you get the less tension or compression forces are applied to the material, in the centre there is equilibrium = no stress. this partly explains why making a beam solid has less effect on stiffness than making it larger, thus moving the tension compression faces further away from each other. Adding material to the centre where the stresses are low is not an efficient use of material.

Filling with Concrete or Epoxy composite materials will increase the vibration damping but not materially increase the stiffness compared to steel they are both less stiff. Using them requires greatly increasing the thickness of the beam or structure as done by the big CNC machine builders.

You also have to consider the strength of a material as opposed to its deflection. Will the beam resist permanent bending damage or creep? will it resist fracture caused by a fluctuating load? (Just like when you bend a piece of wire back and forth to break it). When working with machinery that requires low deflection for accuracy strength normally looks after itself. It should however always be checked and considered.

Regards

John

Edited By John McNamara on 06/06/2015 17:37:00

Ady1.

Ady1.