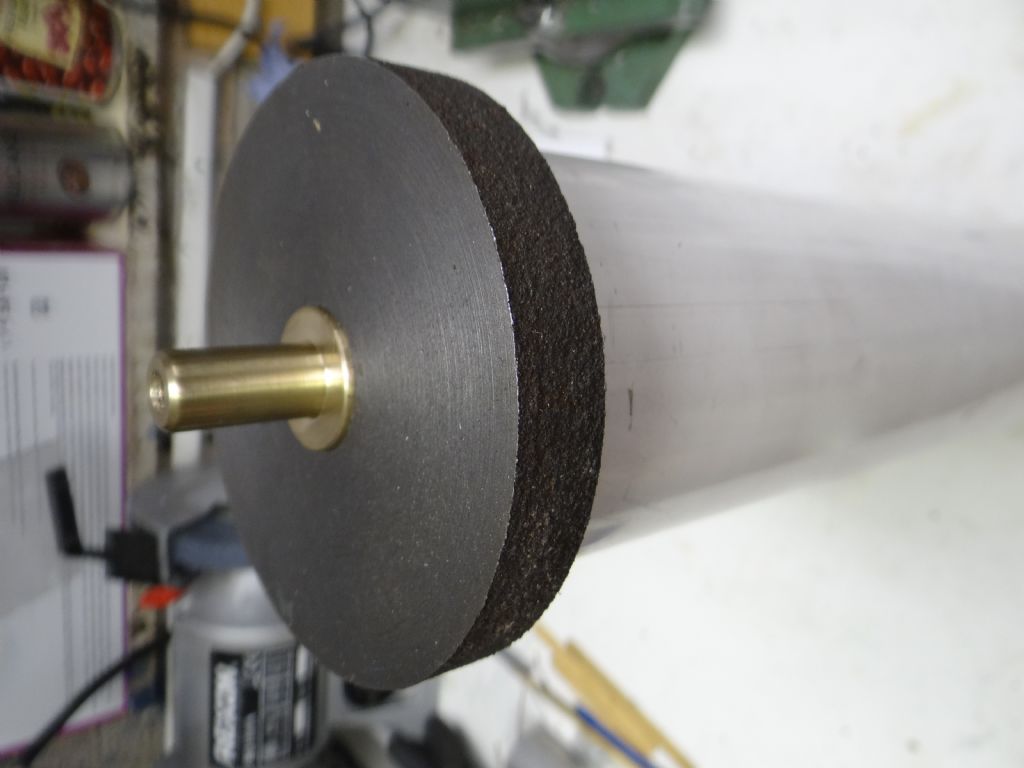

The vacuum tube (a length of 4" diameter PVC soil pipe) is the biggest item I've turned on my lathe.

Only needed to put it in the lathe to turn the rough sawn end of the PVC pipe flat, and far more work went into holding the pipe than to cutting it. Apart from being close to the maximum length that will fit my lathe without taking the tailstock off, PVC pipe is bendy, prone to dig-ins, and liable to melt. Needs to be held firmly whilst being attacked with a sharp cutter.

A sharp carbide insert at low RPM and low depth of cut worked better than HSS. I'm not convinced either is a good choice for turning PVC, but the insert got the job done.

Took me about 10 hours to design and make a mandrel:

It's a length of steel gas-pipe with 4 tapped collars holding a pair of chipboard wheels turned to fit the PVC pipe. . One end is held and spun by the 3-jaw, the other is supported by a dead-centre.

Sod's Law ensured that my live centres are either just too big or just too small to fit gas-pipe, but there's just enough room for the saddle at the PVC pipe end. That was lucky, because I expected to have to take the swarf guard off the lead-screw to get enough travel.

After all the preparation the actual cut was an anti-climax. The HSS tool was rejected after a couple of minutes of nearly cutting, short pause whilst I switched to carbide, and then the real cut took about 30 seconds.

A problem I hadn't anticipated was cleaning the pipe. Wiping off attracted a mass of sawdust and cat-hair due to static electricity. The amount of sawdust made me wish I'd worn a mask: the air was still full of dust at least 90 minutes after I'd made the wooden discs.

Next step is to make or buy a bulkhead penetrator for the wiring. Once that's available, I can take the clock apart and drill the base to fit the penetrator and the vacuum tubing.

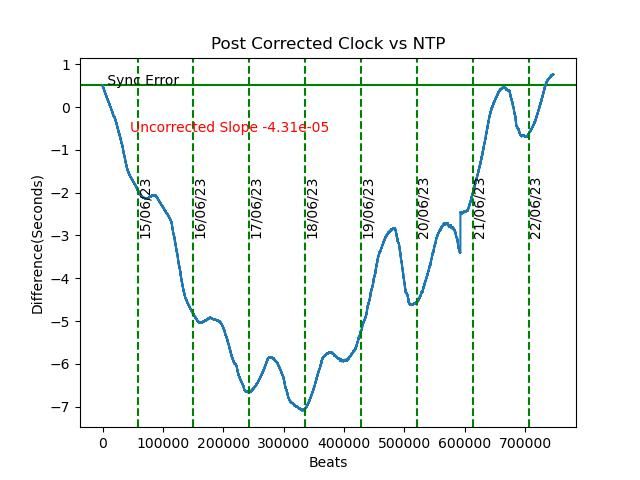

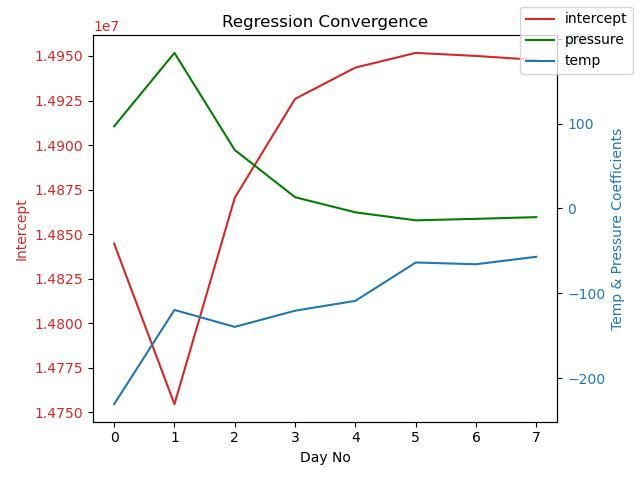

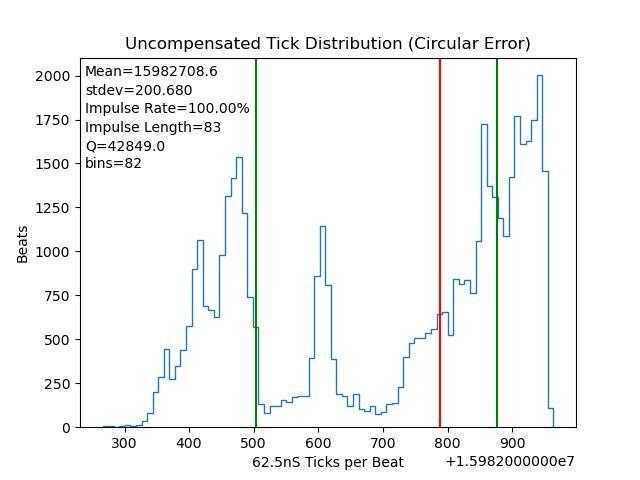

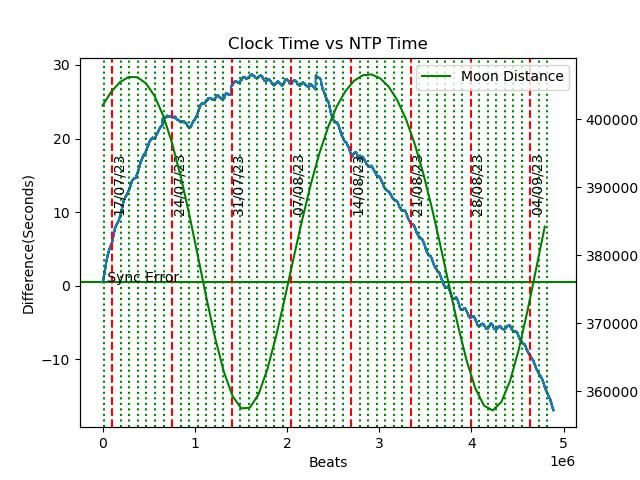

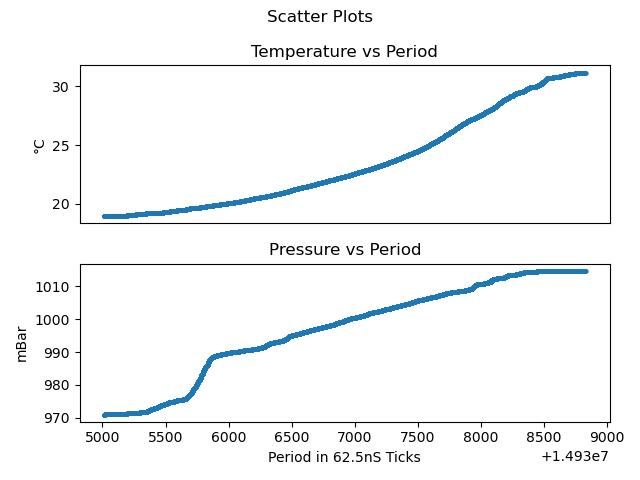

Although the pendulum, electronics and software aren't really working well enough to justify running the clock in a vacuum, I feel the need to get on with the mechanicals. Trouble is testing the software takes at least a week because the clock achieves accuracy by learning how to compensate for temperature and pressure changes. As Mother Nature is fickle and slow, she takes a long time to provide all the combinations. It's caused long delays.

With hindsight, might be quicker to fit the vacuum containment and run the pendulum at a series of fixed low pressures. Running in a vacuum would also validate my assumption that the temperature-pressure formula derived by analysing normal weather is OK for a pumped low pressure. I'm fairly confident but nothing about this project has been straightforward…

Dave

Edited By SillyOldDuffer on 29/06/2023 18:09:20

SillyOldDuffer.