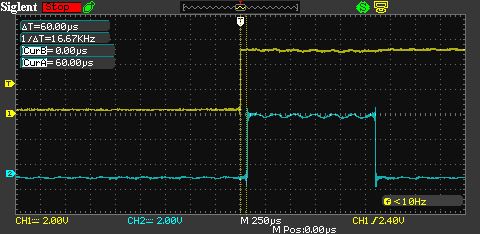

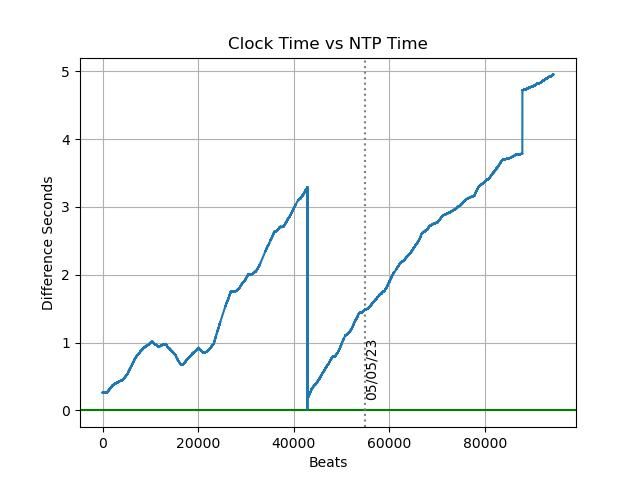

Pleased to report, fingers crossed, that I've fixed an intermittent problem that's been annoying me for ages. It's that,rarely and apparently randomly, the clock registered a double beat. The false beat occurred on the FALLING edge of the beam break, when the microcontroller was programmed to repond only to RISING edges. Should be impossible, and I've been chasing all manner of esoteric and unlikely causes – many hours wasted.

Seems the actual cause was electrical noise on the input. Microcontroller inputs are vulnerable because they're high-impedance, making it possible for them to pick up glitches on long wires, or even from adjacent pins. The cure is to tie the input either HIGH or LOW with a resistor, about 10kΩ. It stops static and soaks up short spikes. Looking very good so far, zero false triggers in over 12 hours.

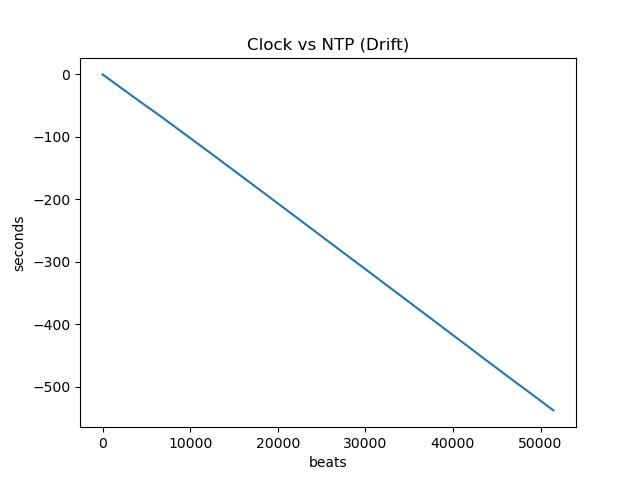

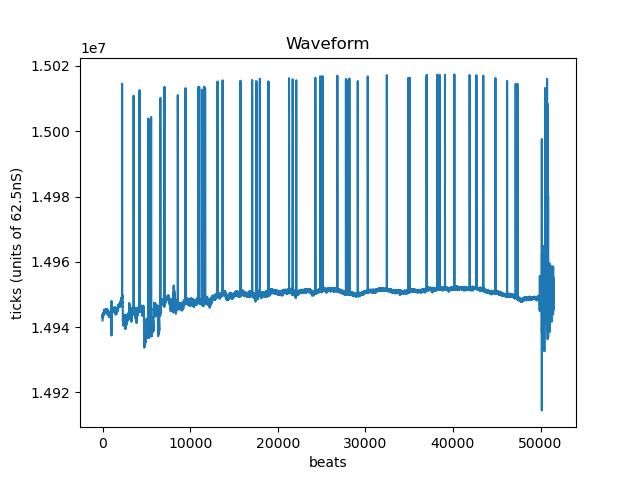

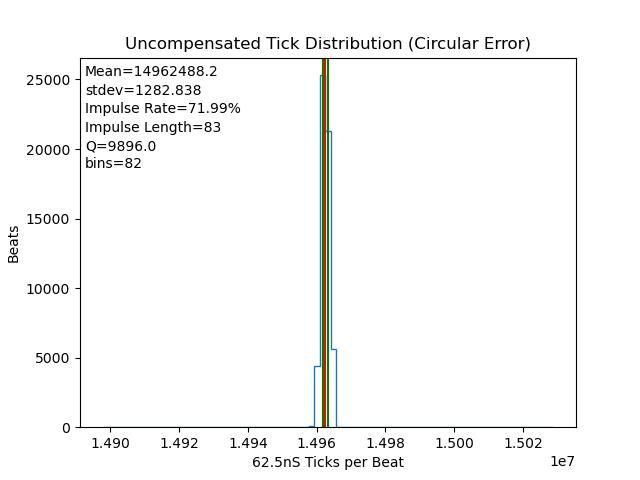

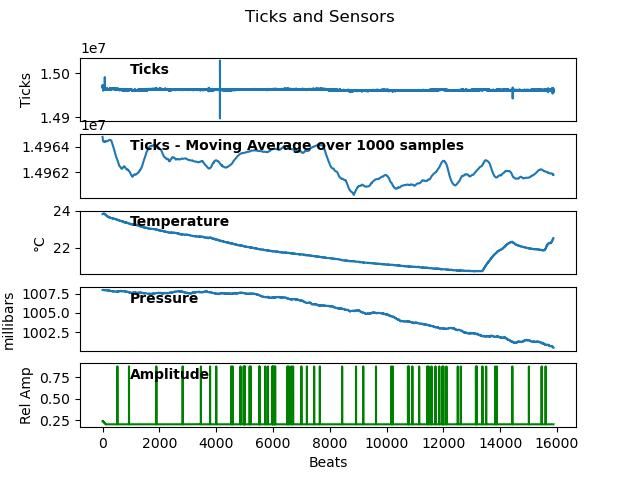

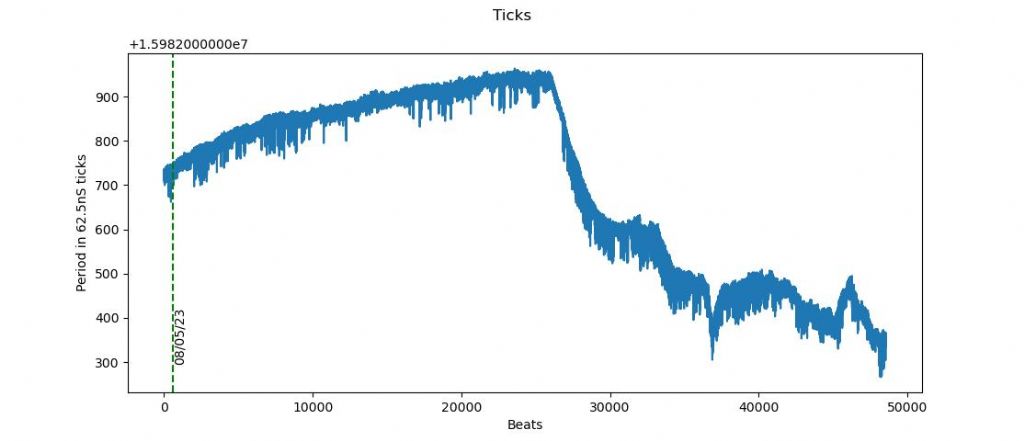

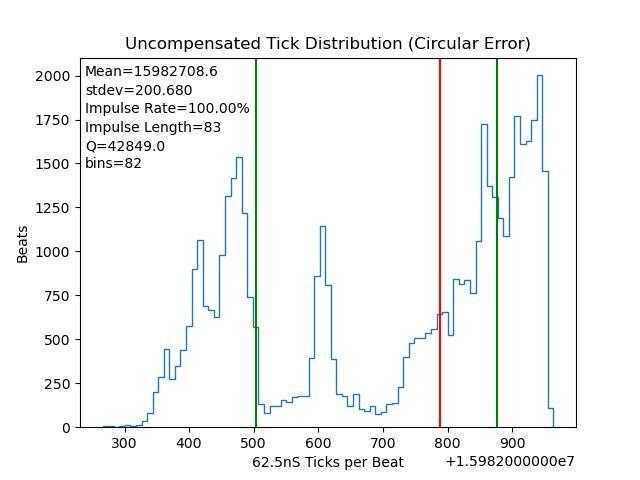

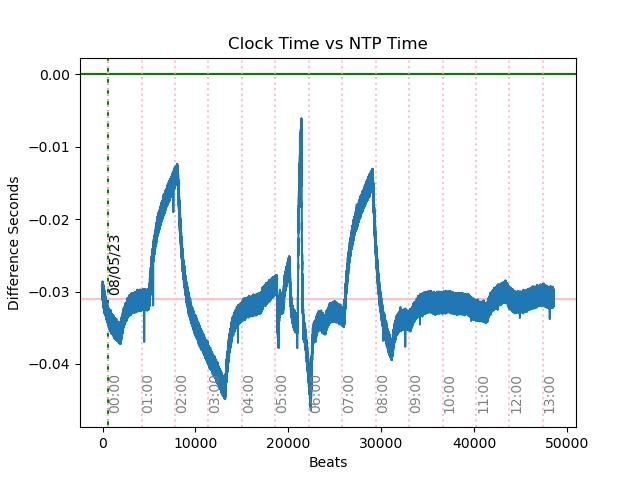

At the moment I'm running the pendulum uncompensated to determine it's characteristics. Nice straight line on the drift graph, and period only varies up to 80 microseconds per beat, much better than the Mk 1 clock, with a sharp evenly balanced distribution, hurrah!

Annoyingly, the good weather is failing to provide the variety of big temperature and air pressure changes needed to calibrate the pendulum: correlations are identified, but not strongly, meaning compensation values based on them won't cover winter and summer confidently.

The spiky green graph shows something is still wrong with the amplitude code or electronics. (I hoped the resistor would fix it, nope!) Even though the error rate is only 0.5%, and the affect of each error on the pendulum trivial, I want to fix it.

Comparing last night's run with actual time this morning showed the the clock should be set to an average period of 0.935266s rather than 0.924012s. Period was set to 0.935266s and the clock reset to UTC this morning. If that works, the clock should run close to UTC, but is still uncompensated. However, weather permitting, it will collect enough tempertature and pressure changes to enable compensation.

Progress is promising enough for me to tackle the vacuum containment problem, difficult enough for it to be worth it's own thread. The parts needed to plumb it have started to arrive.

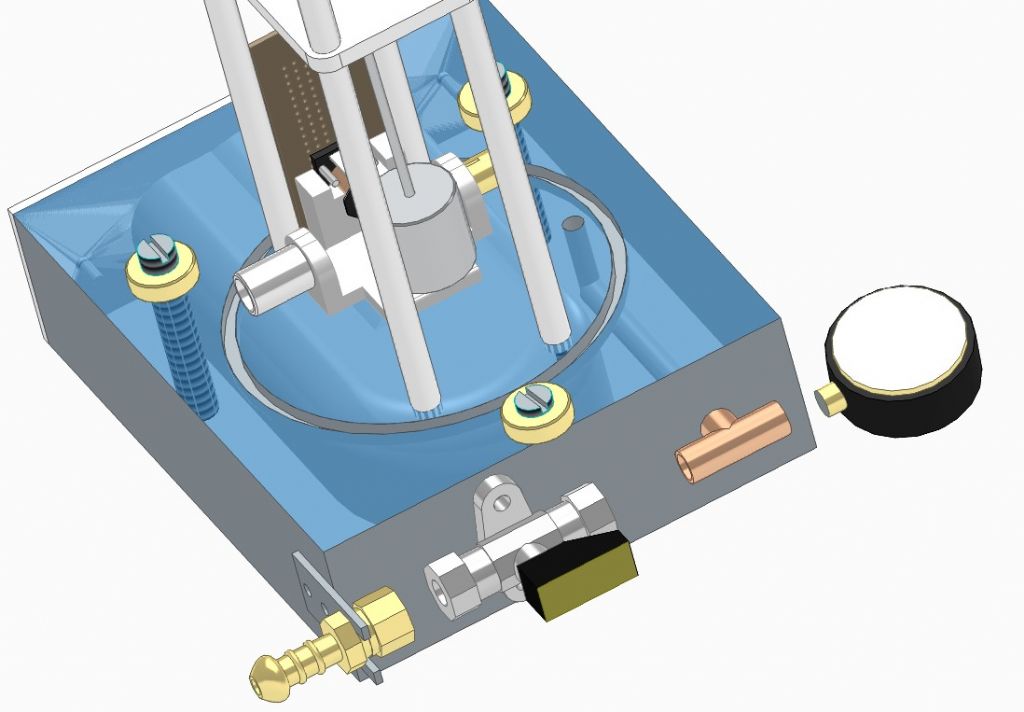

First attempt at plumbing was this:

Rubber hose from vacuum pump attaches to a nozzle connected to a valve, connected to T-coupler. Vacuum gauge on the end. Unfortunately, this configuration requires a ⌀ 6-8mm hole 100mm deep to be drilled accurately straight into the block. If it drifts, there's a high risk it will break out into the lower cavity.

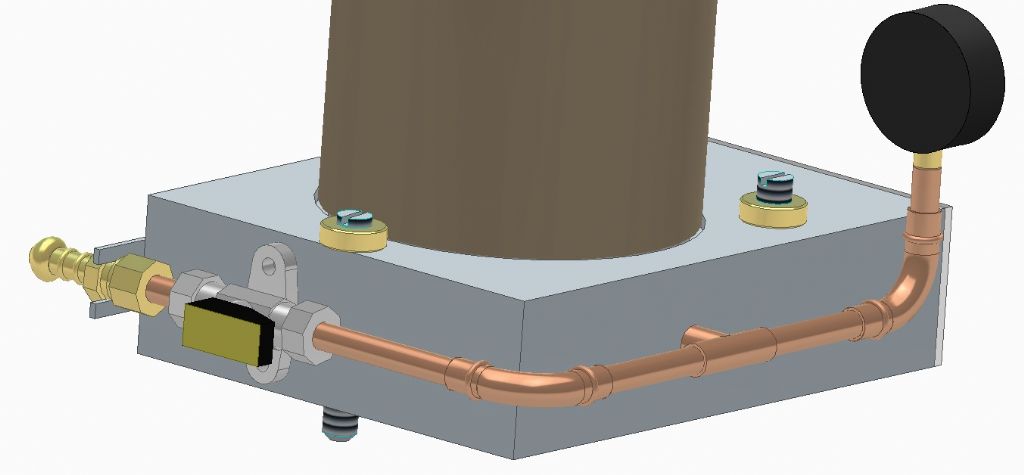

Second attempt avoids the need for deep drilling, but more pipe and joints. The vacuum gauge can be upright at the front:

The more I think about how to contain the vacuum, the more difficult is seems. I'm after a deep vacuum, and yonks ago Roger Atkinson said of my Edwardes EB3A pump "Specification seems to be 26" Hg / 133mB", about 86% vacuum. Not bad for a home clock, but ideally the vacuum has to be held steady for years. The container holds about 2 litres of nothing, so a leak of only 1cc air per day is cause for concern.

Leaks are less worrying if the pump is in poor condition and can't get that low a vacuum, but then the clock won't achieve it's best.

Dave

SillyOldDuffer.