Posted by Joseph Noci 1 on 20/04/2023 12:45:08:

I searched ( tediously) through all the pendulum threads and posts to find what was said about using carbon fibre as the pendulum rod – All I found was related to a carbon fibre in rod form, but not much help beyond that.

… Perhaps this application of carbon fibre has been covered and rejected for good ( or bad?) reasons, but I could not find any reference.

If you really wanted to compensate the Carbon Fibre thermal performance with ambient temp, simply measuring the temp inside the tube would be sufficient – the fibre is so thin, it would hardly differ in temp from the sensor and surrounding low air pressure ( I assume not a high vacuum..).

I blame the forum format because it makes it hard to follow developments, and sometimes there's a long gap between the problem being discussed (haphazardly), and me declaring what I'm doing about it.

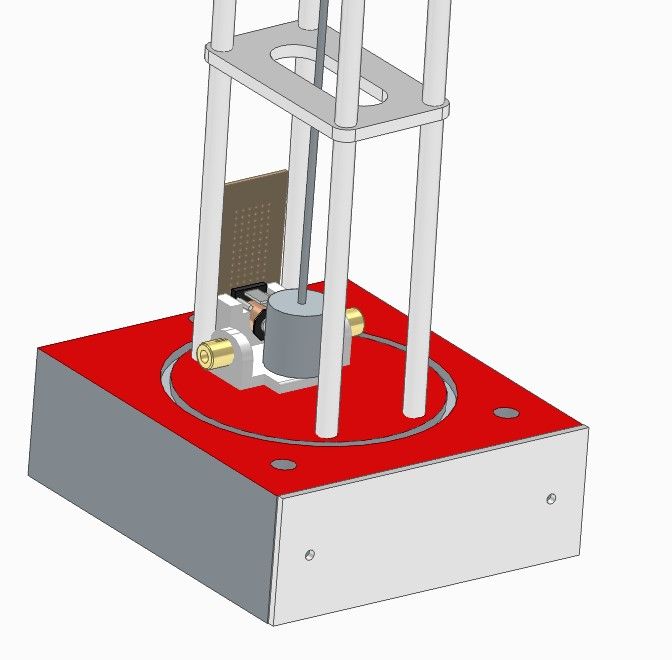

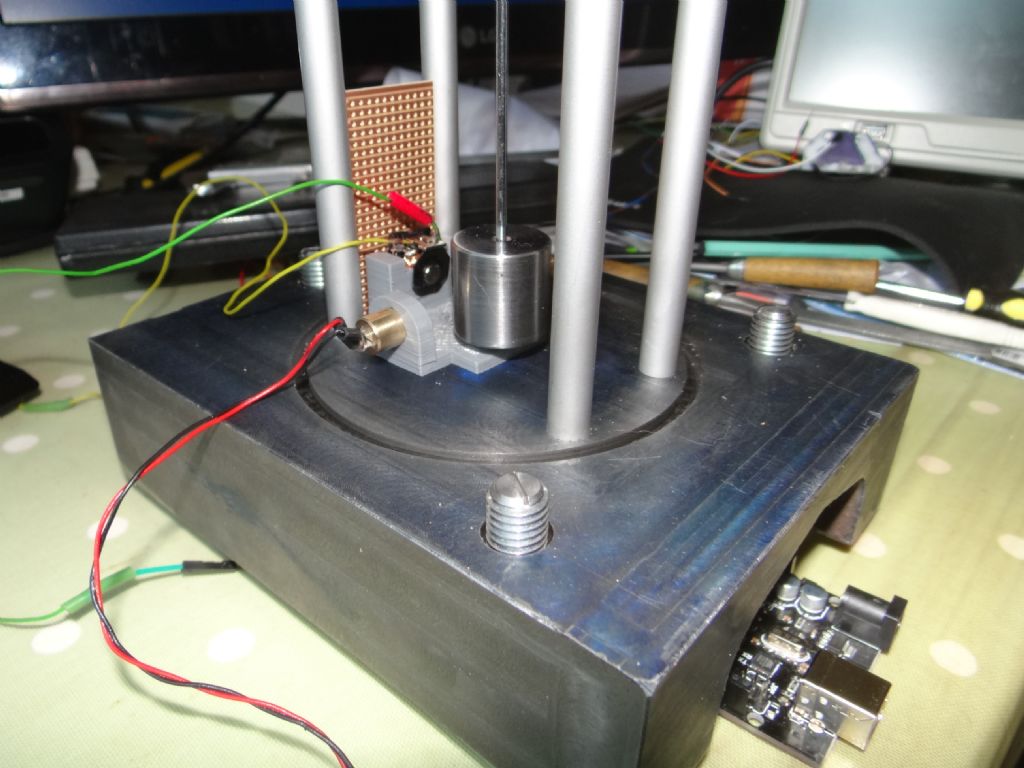

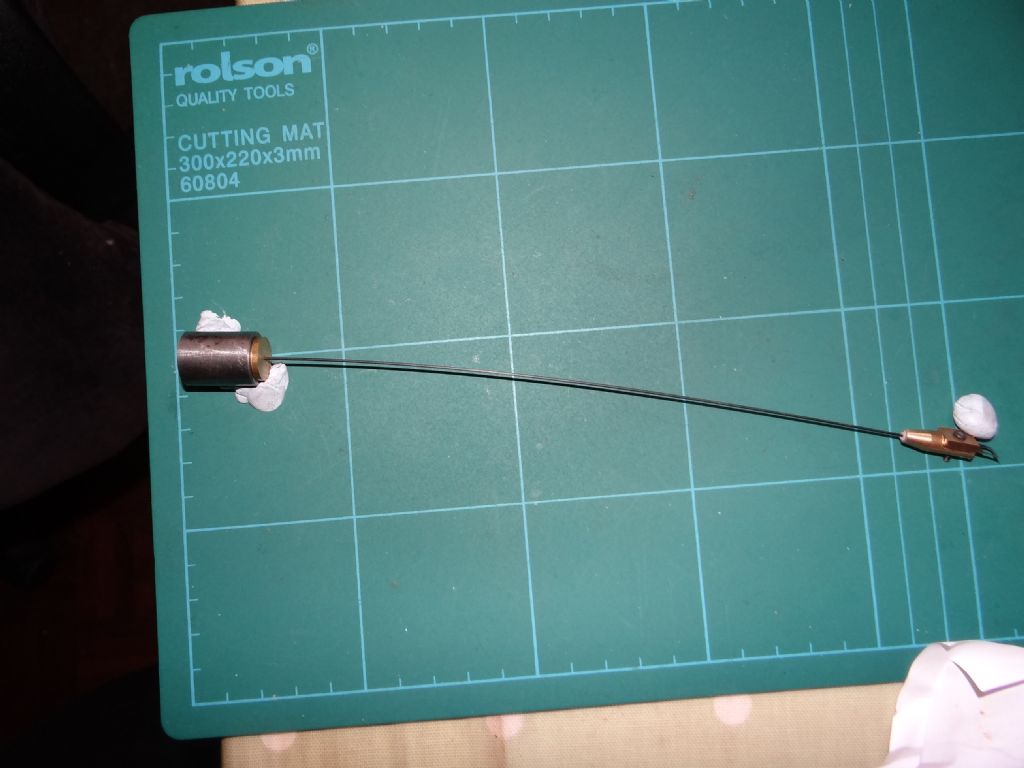

Going back a couple of years, my original idea was to use a thin carbon-fibre as a spring – no suspension at all. Not satisfactory because:

- Carbon fibre rod is humidity sensitive, because (I think), it affects the springiness of the plastic matrix.

- When a conventional spring is inserted, the fibre-rod twangs, which I think explains some of the variation in my pendulum's period.

The fibre is bendy!

So I've switched to steel, assuming that the existing software temperature compensation would cope with it. In true time-nut fashion, that led to the realisation that it's the temperature of the rod that matters, and how to measure it. Plus the rod is well-insulated and will lag behind ambient by some time because it's heated by a circuitous route.

I don't intend to tackle the problem until running the clock in a vacuum shows this to be worth fixing. It's possible the clock and pendulum have so many other faults that this one will be undetectable! An Invar or much thicker fibre rod is also on the cards. It's all experimental!

Dave

SillyOldDuffer.