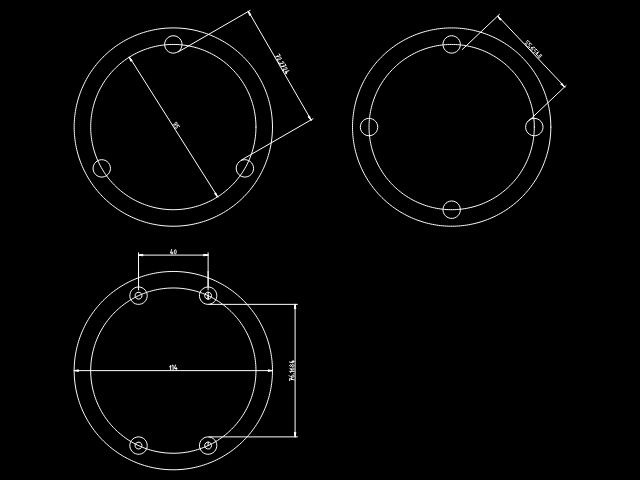

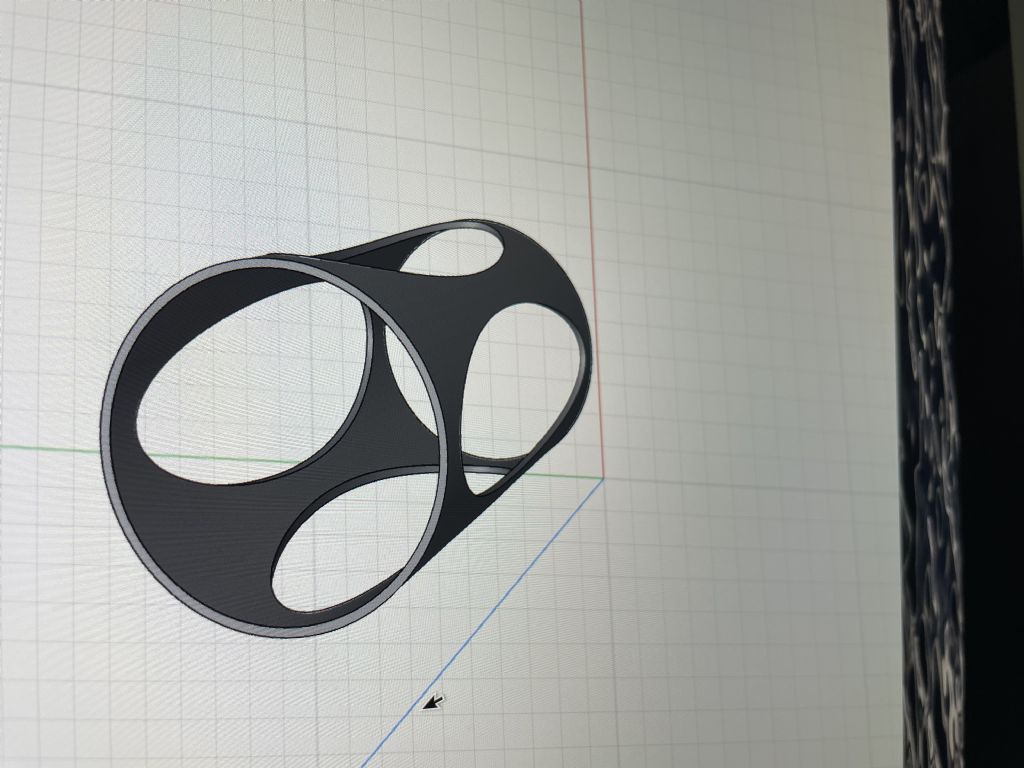

Played with some pillar layouts last night with 2D QCAD, which is easier to use for this job than SE:

I measured the space available for my fingers between pillars in three vertical configurations. Equalateral-tripod, square-quadripod, and rectangular-quadripod. Sorry about the blurred numbers – the tripod gives 72.3mm access, square 57.2mm, and the rectangle 70.77mm.

My hand: 4-fingers across = 90mm, 4 fingers + thumb = 110mm, and forefinger + thumb = 40mm.

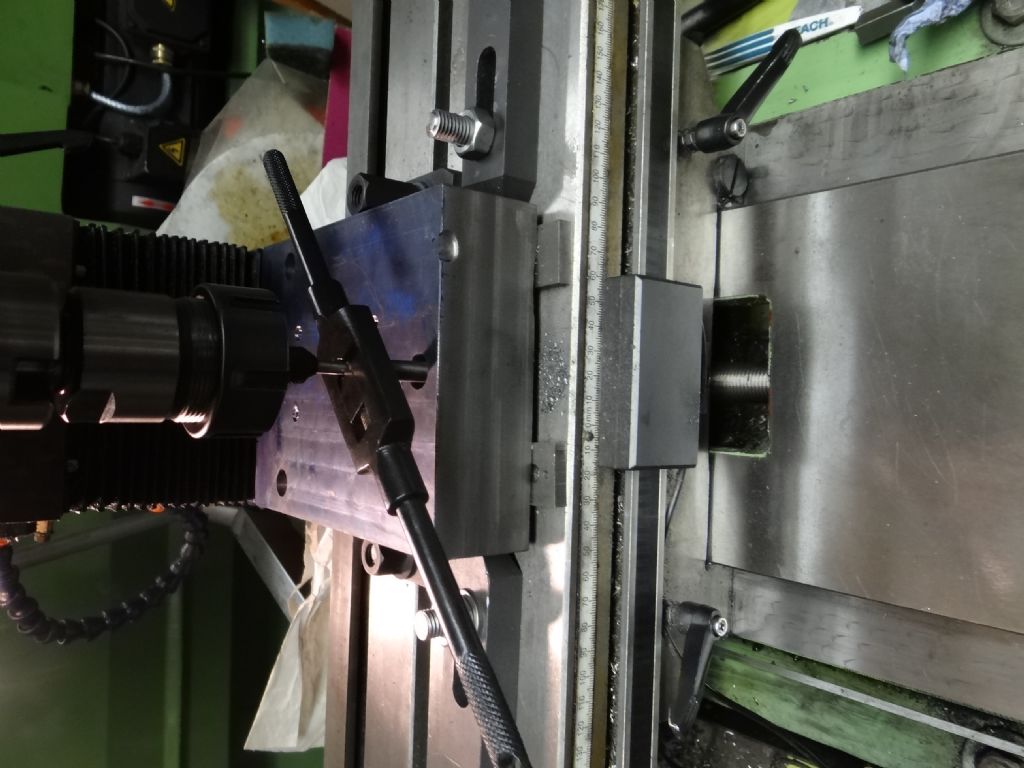

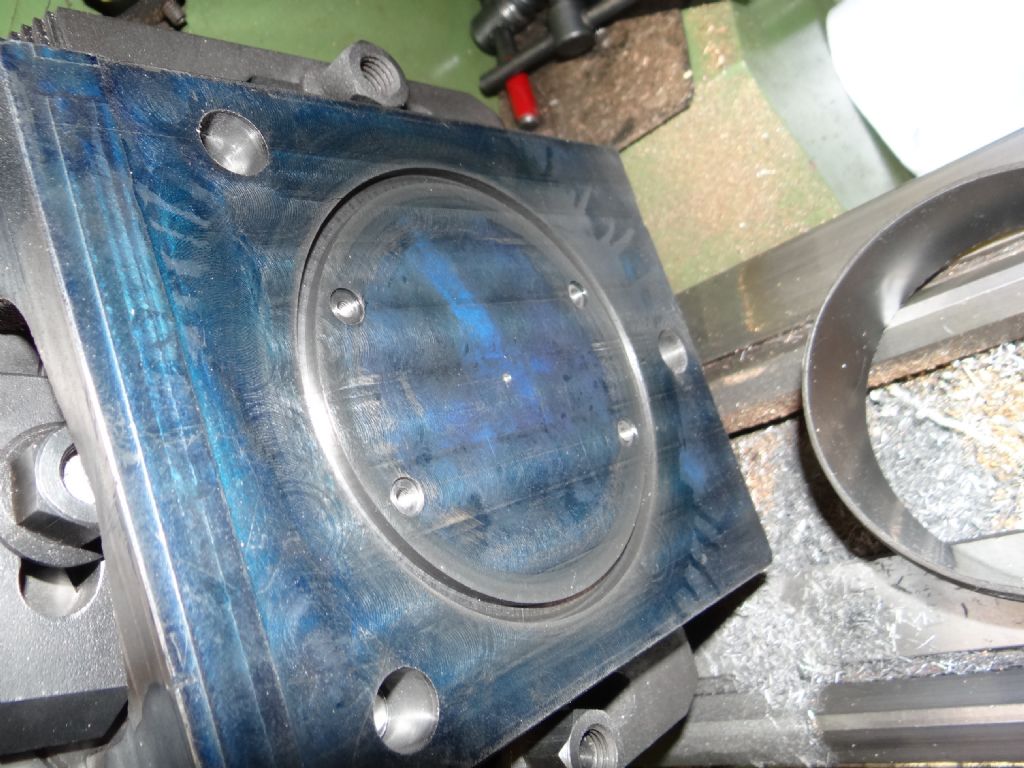

The advantage of vertical pillars is space and simplicity of construction. A tilted tripod supporting a 240mm high platform would be angled at about 75°, requiring me to drill diagonally into the base and platform. Could be done, but it's harder to do and more error prone than going straight in with a milling machine. Perhaps in the Mk V!

The equilateral triangle both maximise stability, whilst the rectangle gives better access in exchange for less stability sideways (compared to a square.)

Spent this morning reading about columns with discouraging results. Apart from the maths boiling my brain, my book says things like "Great and apparently insuperable difficulties arise as soon as we attempt to obtain expressions which relate the strength of longer or more slender columns to their various dimensions."

It usefully explains why circular pillars are better than square or other shapes, the importance of fixing the ends, and would help if knowing the safe load was a concern. The safe load doesn't matter because my bob only weighs about 40g and even a spindly tripod will easily support it. And then the chapter on eccentric loads, which covers my case, doesn't cover dynamic loads (a moving pendulum), or say anything about rigidity, which is my chief concern!

I hope Solid Edge's Simulation tools will help, but frankly have to admit I barely understand the basics.

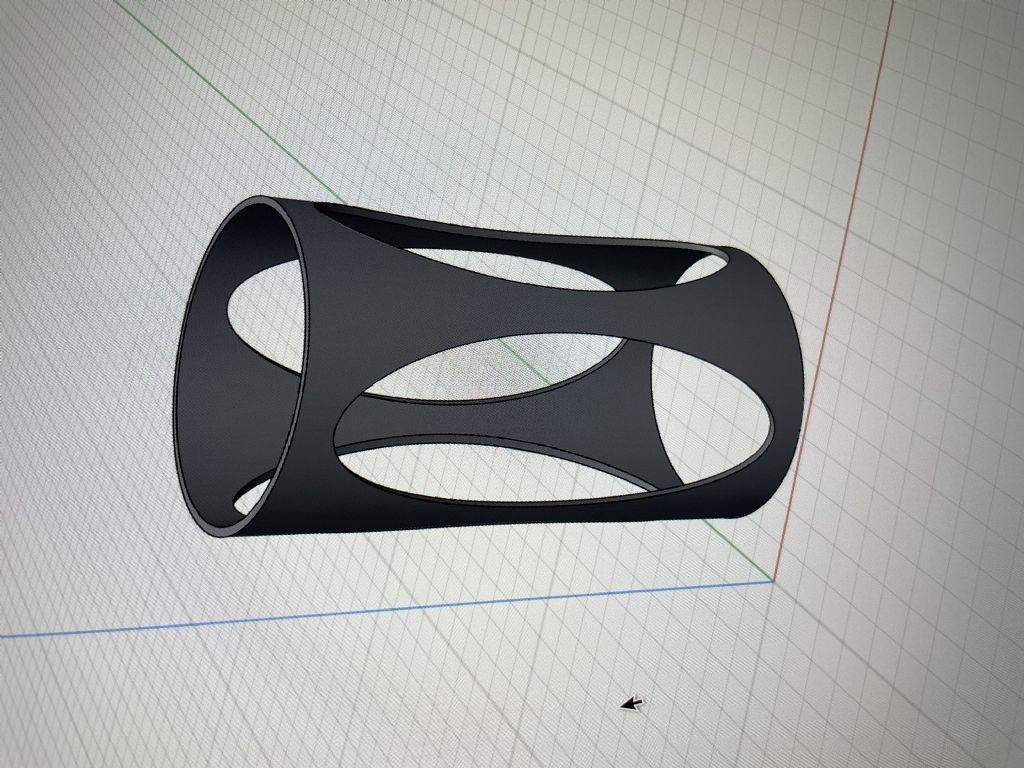

Going to spend an hour pondering what to do whilst de-scaling cast-iron in the snow. I guess cross-bracing a quadripod is the answer, but I'm not sure how to do it whilst allowing access. Before deciding, I need to model the chariot that carries the sensors and electromagnet. Either it fits through the gap or I have to emplace it first and then erect the scaffold around it. Hmmm.

Dave

SillyOldDuffer.

Dave

Dave