Posted by Martin Kyte on 06/03/2023 11:49:58:

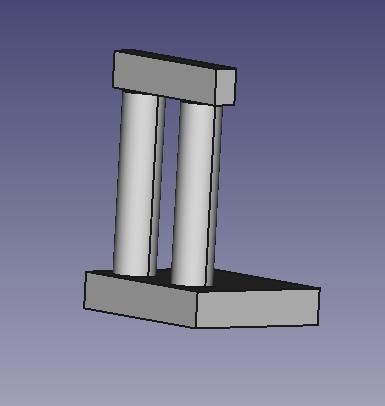

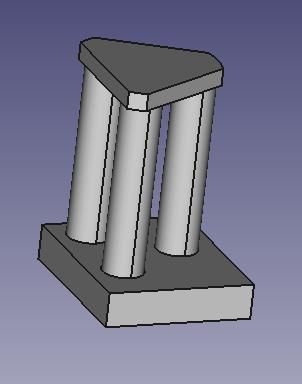

Perhaps I’m missing something but if you arrange the uprights (3 or 4) to be outside the tube clamping the tube between the top and bottom plate the Tube becomes the rigid member. This gives the option of functionally testing all the electronics without the tube and then fully assembling to test properly. Of course if you bolted the whole lot to a wall by the top plate life would be a lot simpler and the pendulum support much more rigid.

I’ll shut up now.

regards Martin

Please don't shut up, that's a valid suggestion.

I've gone with floor-standing because I don't have a suitable wall, not because I believe a tripod to be best approach. Running the pendulum in a vacuum and the need for access during set-up are influences too.

When the clock is evacuated, or the vacuum leaks over time, I expect the tube to move, which would disturb time-keeping if the pendulum was supported by it. So, at the moment, the tube only connects at the base.

John Doe's solid cylinder idea would provide excellent rigidity, but horrible access problems. I base the comment on experience with the Mk1 clock, where the tripod fitted inside a 68mm diameter drainpipe. Left precious little room for the internals and my fat fingers. Even the anti-buckling ring was a nuisance.

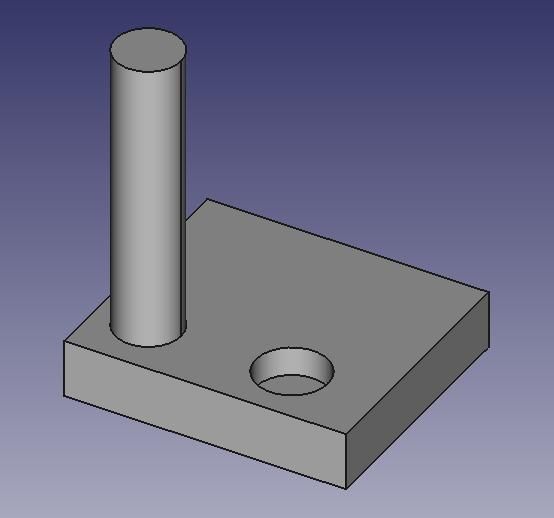

I'm almost persuaded to go with four pillars. Not needed for strength, but rigidity is important. Not much work either.

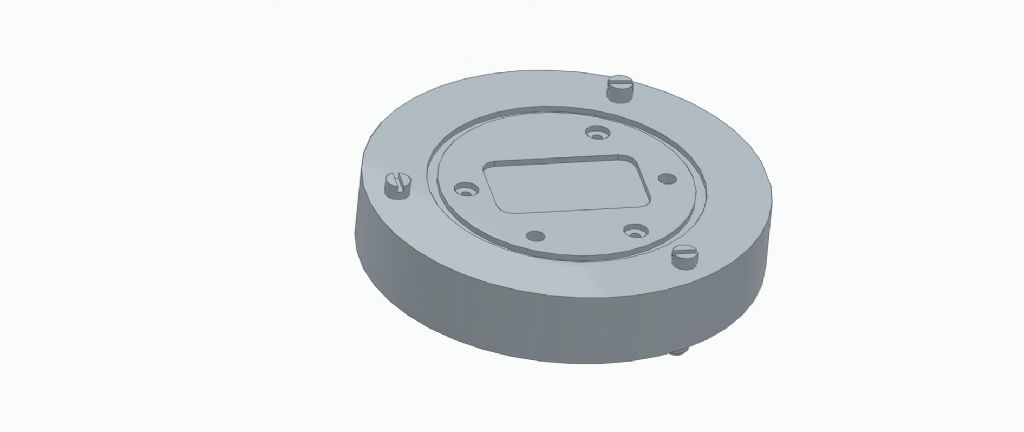

Meanwhile, metal mangling not going as well as it might have done. Strictly speaking only the top needs to be machined, but I'm tidying up. The base machined OK, and I flipped the block to do the top. I rip the scale off with a carbide cutter, then finish with HSS. On top, the scale is thicker, and the casting surface ponded slightly. I should have gone deeper with the carbide because cleaning up the rough cut shows I didn't get down to bare metal over about half the area.

Not the end of the world, but machining scaly cast-iron is a dirty job and unkind to cutters!

Apologies for the chunky tripod post. Intended to explain and clarify, it did the opposite.

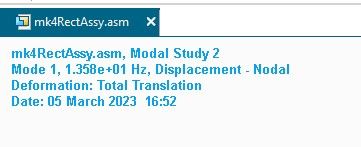

I was pleased to find SE includes vibrational analysis, but can't claim to understand it. It can do 3 modes which I haven't explored because I crashed it last night attempting an analysis with the tube cover fitted. SE goes through a number of set-up stages before doing the analysis, and I guessed, which often ends in tears.

Dave

Dave

Edited By SillyOldDuffer on 06/03/2023 16:01:39

SillyOldDuffer.