Paul,

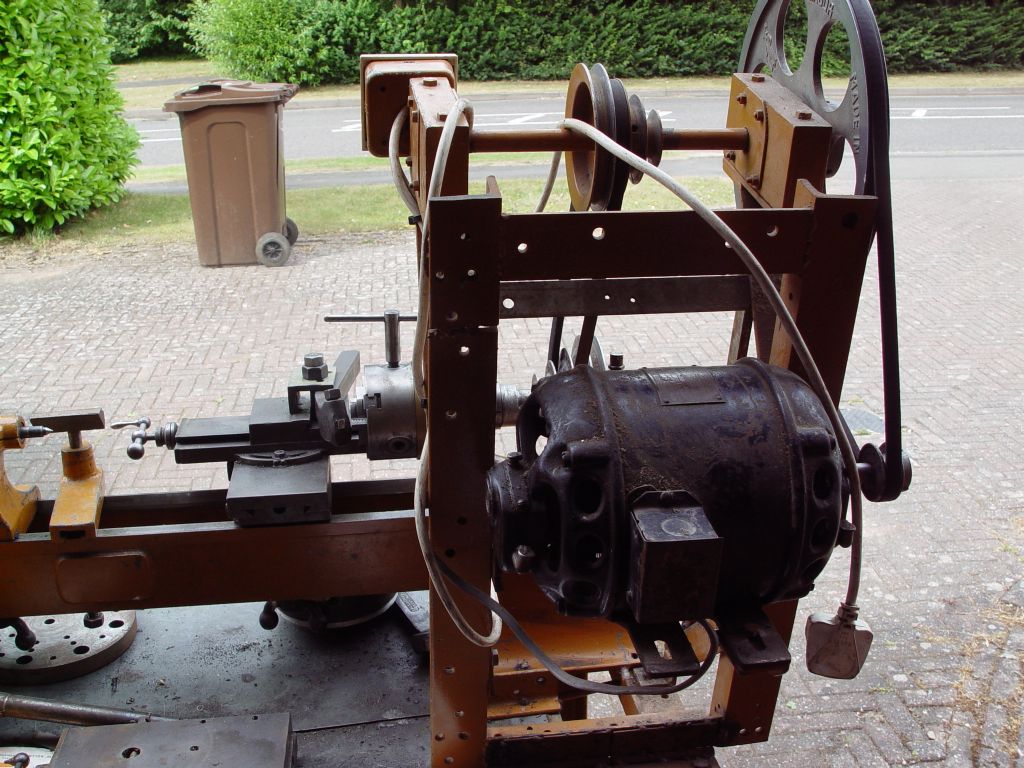

Brian has given you the best link available to try to establish which lathe is in question. The fact that it would come with tooling and accessories has to be a big plus-point in deciding whether to purchase or not. From a brief look at the lathes.co.uk site link, it would appear that the lathes are all roughly Myford size and I would be very surprised if you couldn't utilise a secondhand Myford layshaft, with or without the clutch, without too much jiggery-pokery.

I am assuming that you are UK based as that will make a difference to the validity of the advice you receive in terms of availability of suitable parts. I surmise that original replacement parts will be extremely difficult to source, if not impossible, as you appear to have found.

The drive system used in the designs shown on Tony Griffith's site were very common and similar for a large number of lathes of that era and I'm sure that a lot of them could be modified to fit. As Dave Halford has said, keep the drive and driven pulley sizes mirrored for the reason stated and use the motor to layshaft pulleys to obtain an acceptable speed range overall.

Good luck and let us know how you get on.

John

David George 1.

David George 1.